Sealing sphere flange structure tool provided with sealing groove structure

A technology with sealing and sealing grooves, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., and can solve the problems of different tightening torques and leakage of flange sealing structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

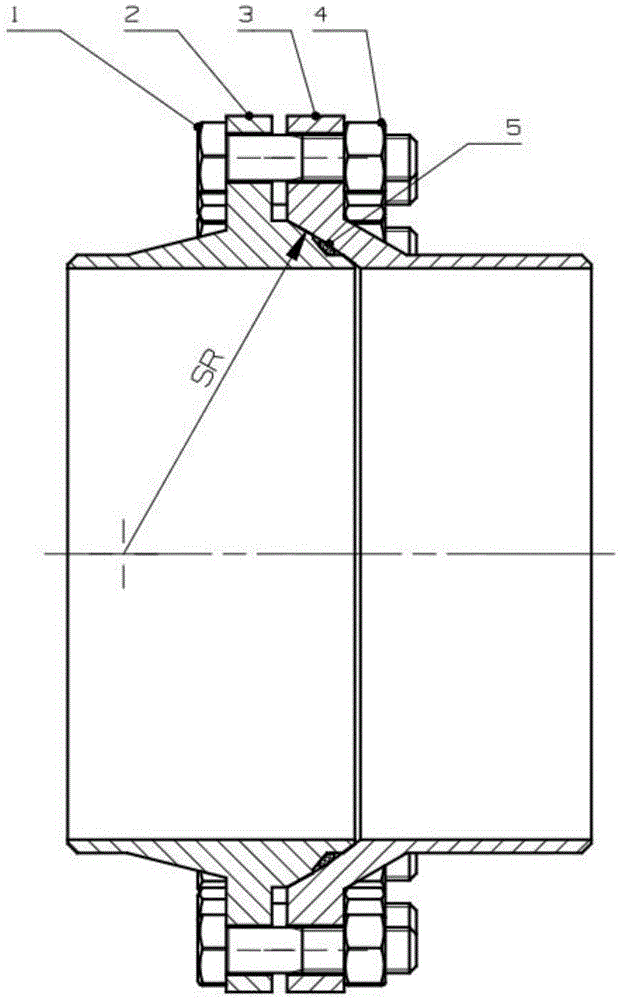

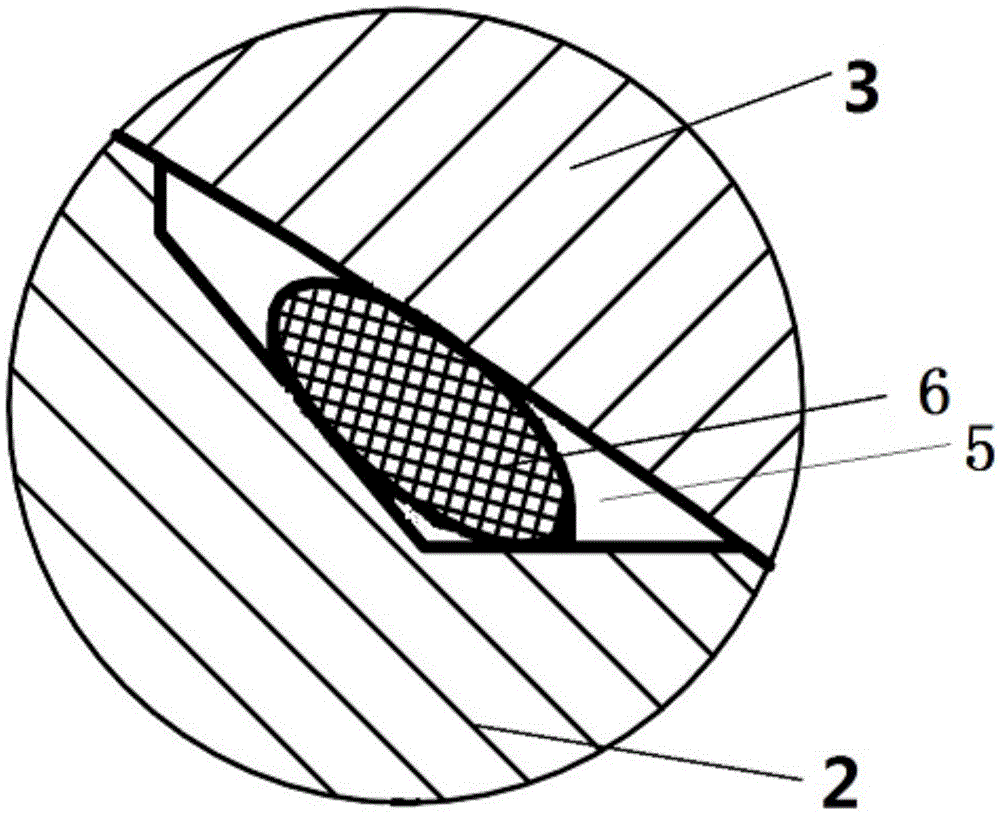

[0012] The present invention is a sealing spherical flange structure tooling with a sealing groove structure, the structure is as follows figure 1 As shown, it includes a concave spherical flange 3 and a convex spherical flange 2 that are connected in an anastomotic manner. There is also a sealing groove 5 on the connecting surface of the convex spherical flange 2 and the concave spherical flange 3. The sealing groove 5 adopts a lathe processing method, such as figure 2 As shown, there is an O-ring 6 built into the sealing groove 5, wherein the O-ring 6 is a standard part, and a nut 4 runs through the edge of the concave spherical flange 3 and the convex spherical flange 2, and is fastened by a bolt 1, wherein , the concave spherical flange 3 and the convex spherical flange 2 are large-diameter spherical surfaces, and the spherical radii are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com