Pneumatic conveying type automatic mold powder feeding device

A technology of pneumatic conveying and mold flux, applied in the field of pneumatic conveying mold flux automatic adding device, can solve problems such as hindering workers' operation, difficult production, narrow space, etc., so as to reduce labor intensity of workers, avoid slag leakage and dust, and improve surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments, but the present invention is not limited to this.

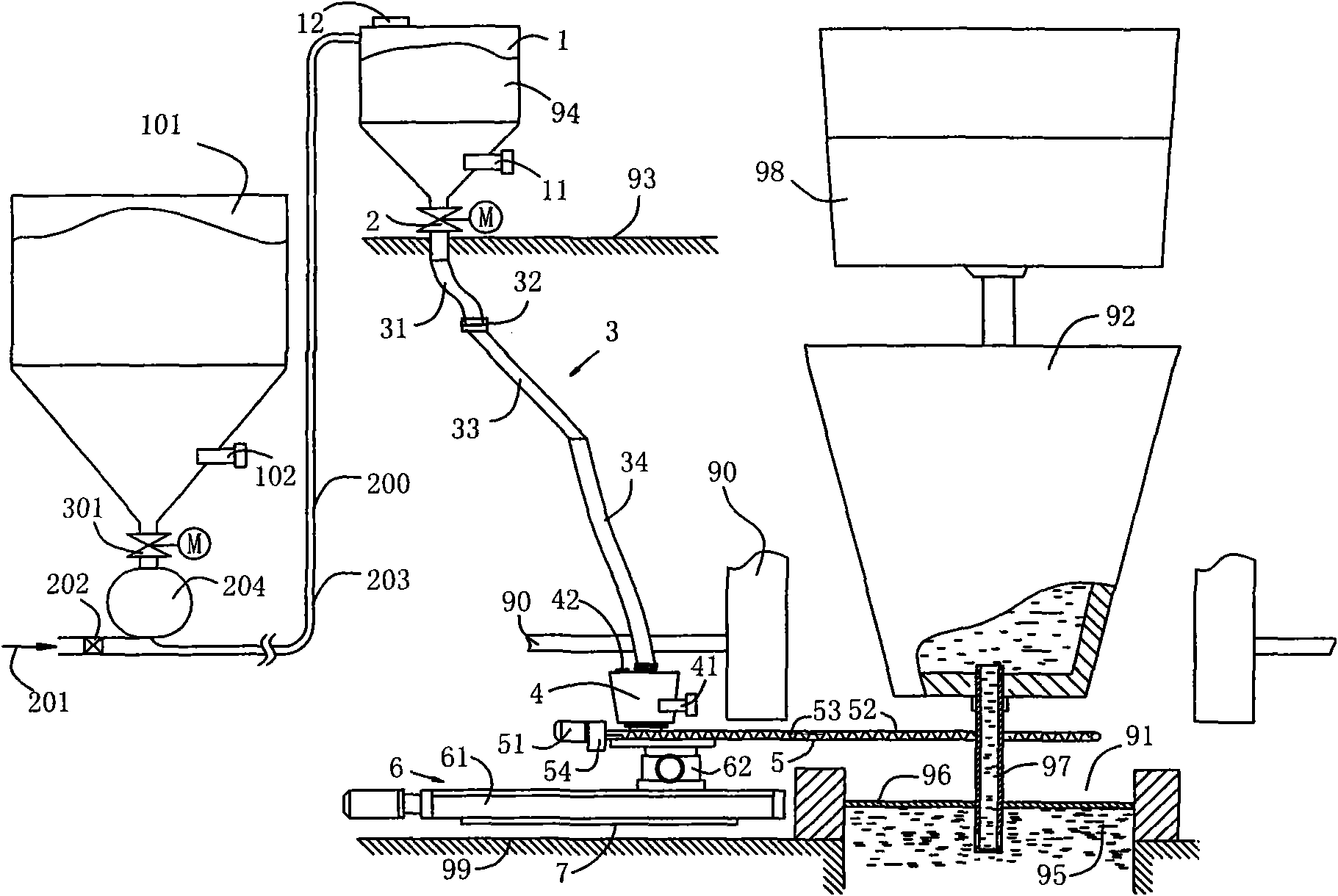

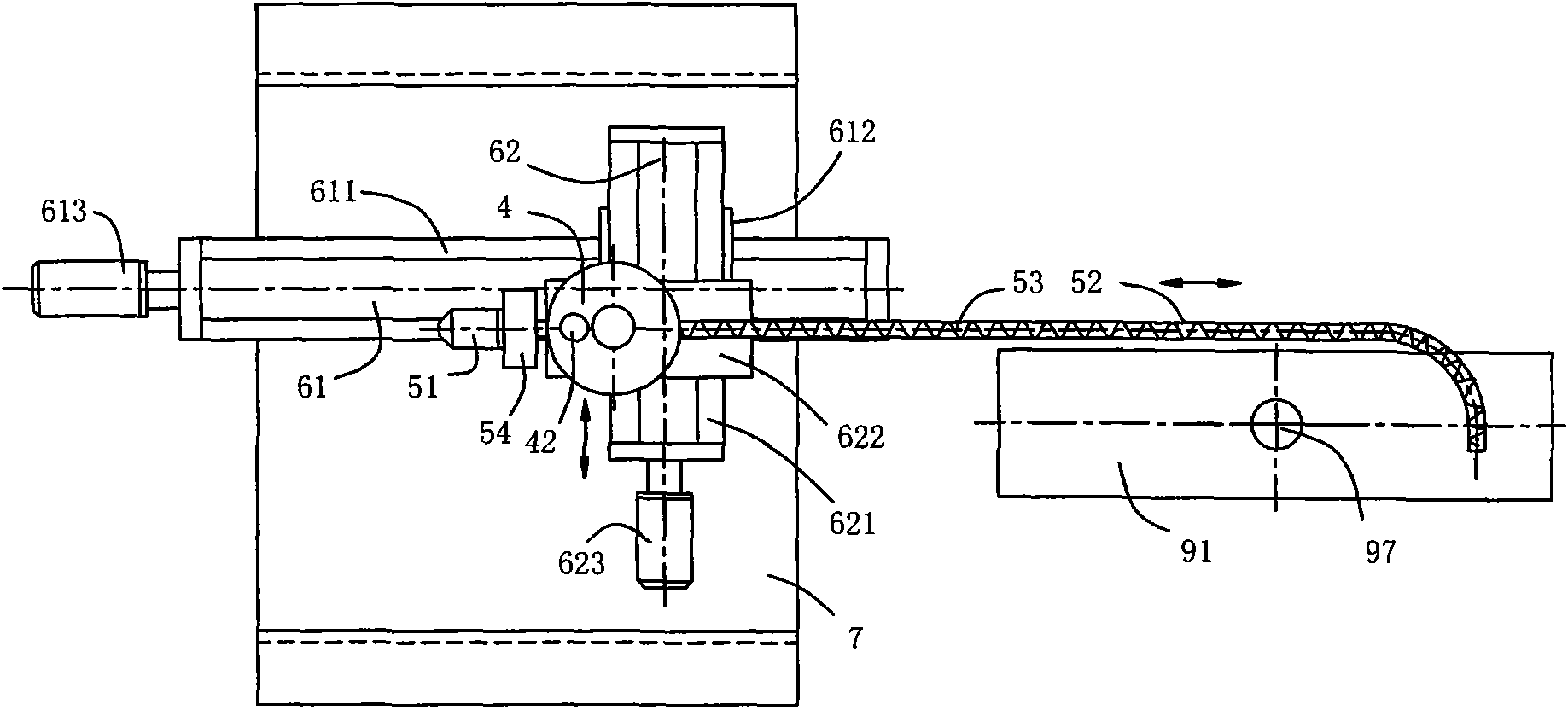

[0042] The pneumatic conveying type protective slag automatic adding device of the present invention is such as figure 1 , 2 As shown, it includes a large silo 101, a pneumatic conveying device 200, an intermediate hopper 1, an electric valve 2, a feeding pipe 3, a small hopper 4, a screw feeder 5, a two-dimensional motion mechanism 6 and a base 7. The large silo 101 is located far away from the crystallizer 91 and is used to store a large amount of protective slag; the pneumatic conveying device 200 is connected to the large silo 101 and the intermediate hopper 1, and the protective slag is removed from the large slag by pneumatic conveying. The silo 101 is transported to the intermediate hopper 1; the lower outlet pipe of the intermediate hopper 1 is communicated with one end of the feeding pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com