High-efficiency energy-saving and emission-reduction dust remover

A high-efficiency, energy-saving, dust collector technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of high one-time investment cost, complex supporting facilities, and high maintenance costs, and achieve low one-time investment cost. The effect of low maintenance cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

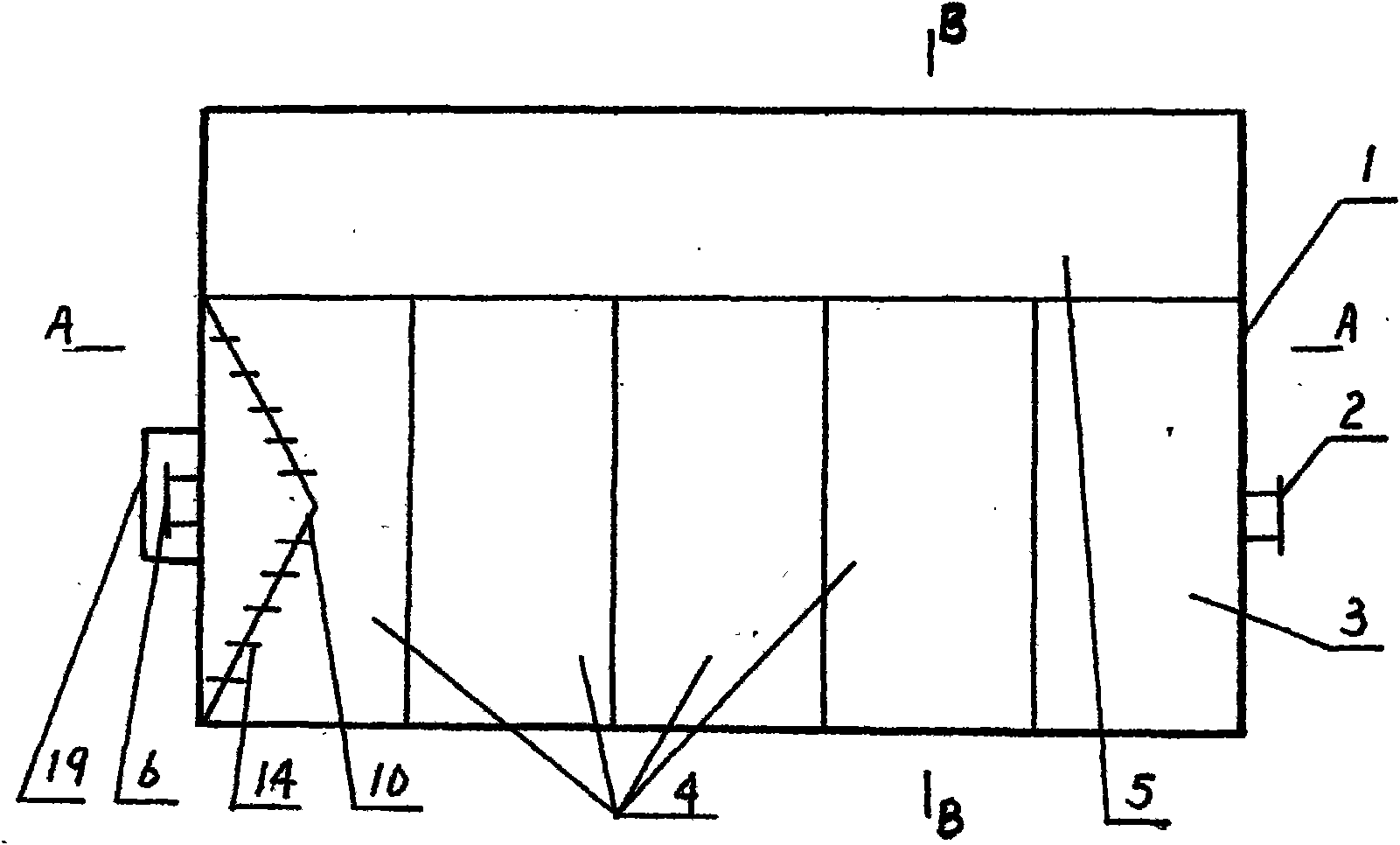

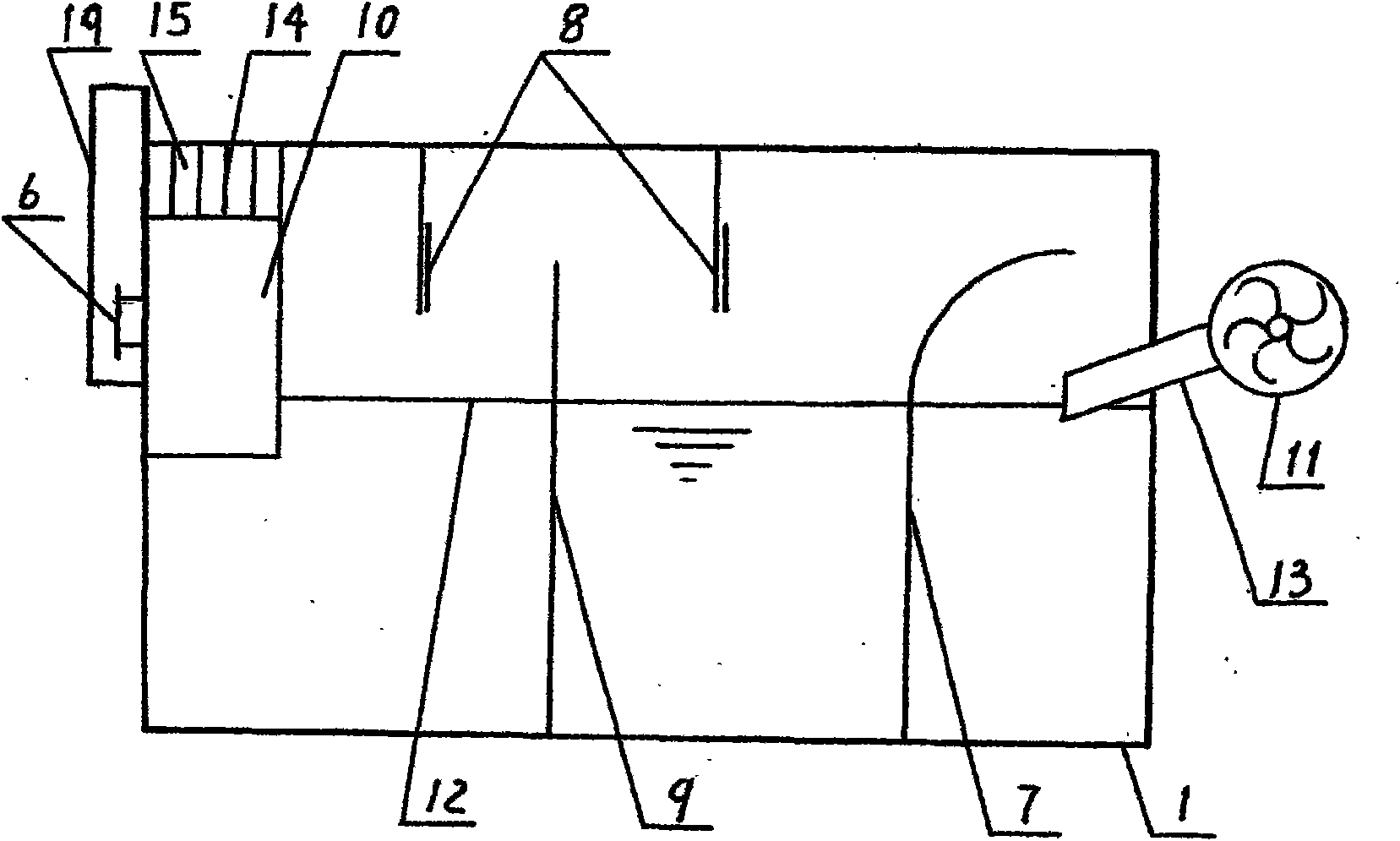

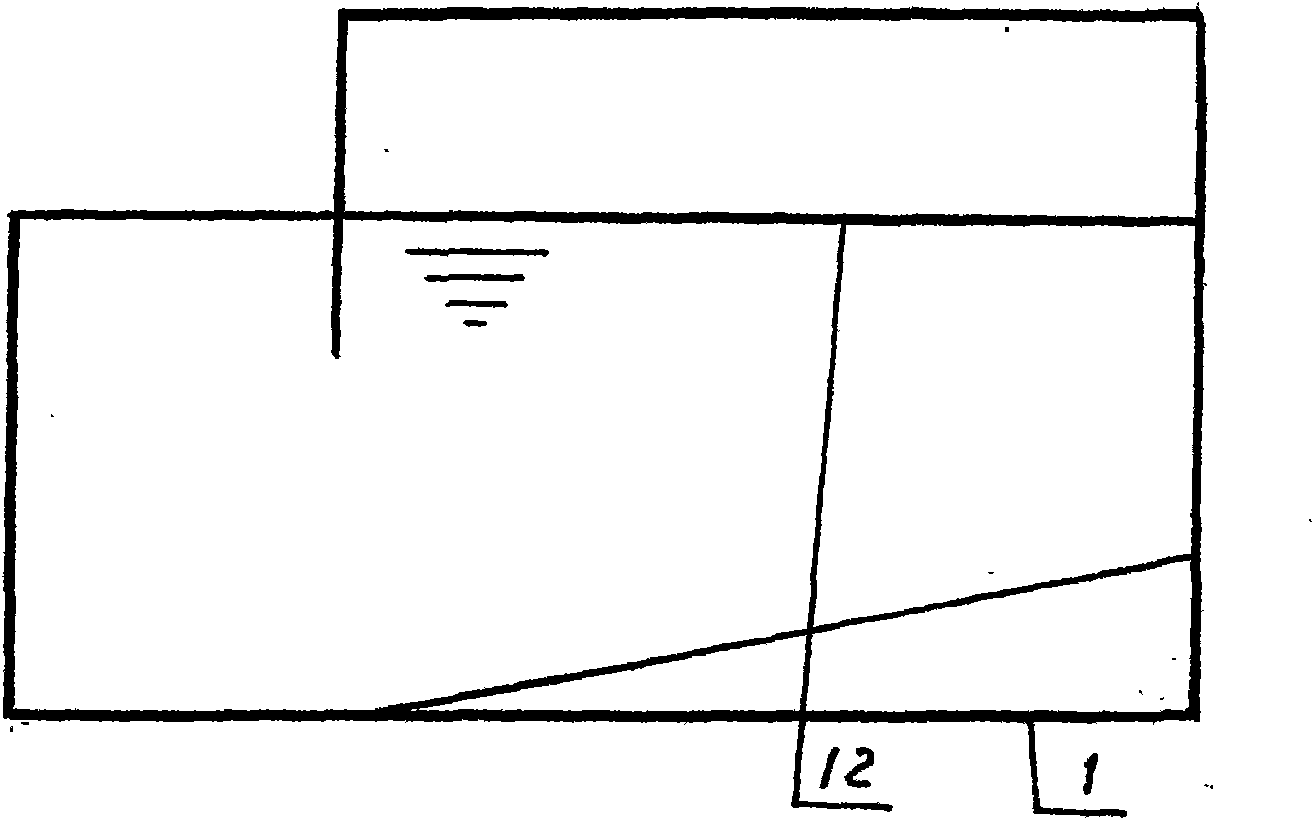

[0019] See figure 1 , figure 2 and image 3 , is a high-efficiency, energy-saving and dust-reducing dust collector with a reinforced concrete structure, consisting of: dust collector shell 1, flue gas inlet 2, fog-making bin 3, dust-reducing bin 4, decontamination pool 5, purified gas outlet 6, fog-making arc plate 7 , automatic adjustment baffle 8, fixed baffle 9, gas purification partition 10, induced draft fan 11, flue gas pipe 13 and purified gas discharger 19, in the dust collector shell 1 is provided with a mist making chamber 3 and a dust suppression chamber 4 and the decontamination tank 5, the bottoms of the mist-making chamber 3 and the dust-removing chamber 4 are slope-shaped and connected with the decontamination pond 5, and the fog-making chamber 3 and the dust-removing chamber 4 are isolated from the atmosphere by a water seal.

[0020] The dust collector shell 1 is made of reinforced concrete with a rectangular parallelepiped structure, on one side of which i...

Embodiment 2

[0027] See Figure 4 and Figure 5 , is a high-efficiency energy-saving and dust-reducing steel structure, consisting of: dust collector shell 1, flue gas inlet 2, fog making chamber 3, dust reduction chamber 4, water tank 16, purified gas outlet 6, fog making arc plate 7, automatic It consists of adjusting baffle 8, fixed baffle 9, gas purification partition 10, induced draft fan 11, flue gas pipe 13 and purified gas discharger 19. Inside the dust collector housing 1, there are fog making chamber 3 and dust reduction chamber 4. A water adding tank 16 is provided outside the dust collector housing 1 through which water is replenished.

[0028] The dust collector shell 1 is made of steel structural parts into a rectangular parallelepiped structure, and a conical sludge bin 17 and a sewage valve 18 are provided at the bottom. The inlet end of the dust collector shell 1 is provided with a flue gas inlet 2. The outlet end of the outlet is provided with a purified gas outlet 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com