Method and apparatus for producing insulated wire

A technology of insulated wire and manufacturing method, which is applied in the direction of cable/conductor manufacturing, insulator, and conductor/cable insulation, etc., can solve the problems of increasing manufacturing cost, increasing the thickness of insulating film, and being expensive, and achieves stable manufacturing and improved viscosity. the effect of combined performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

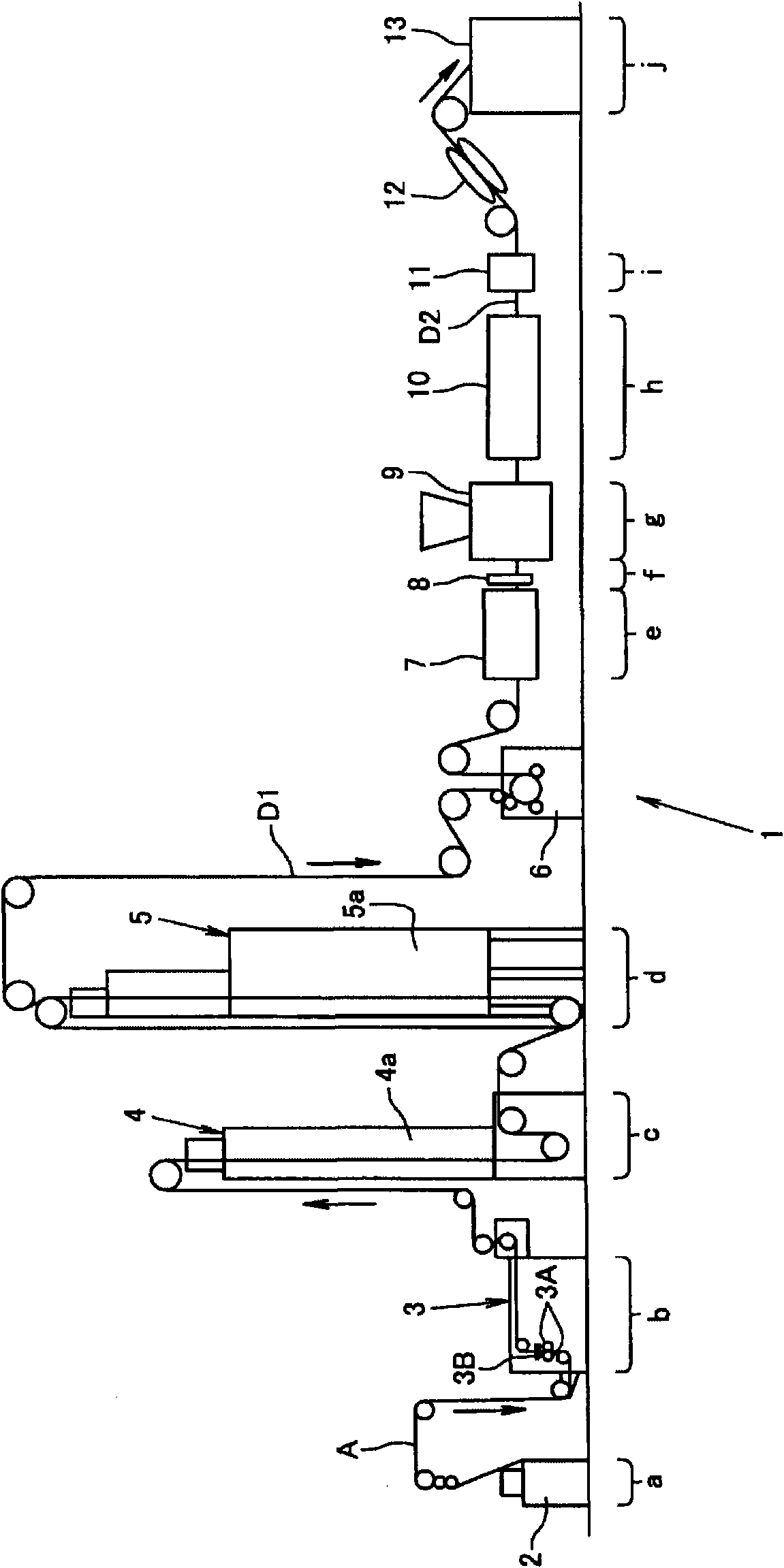

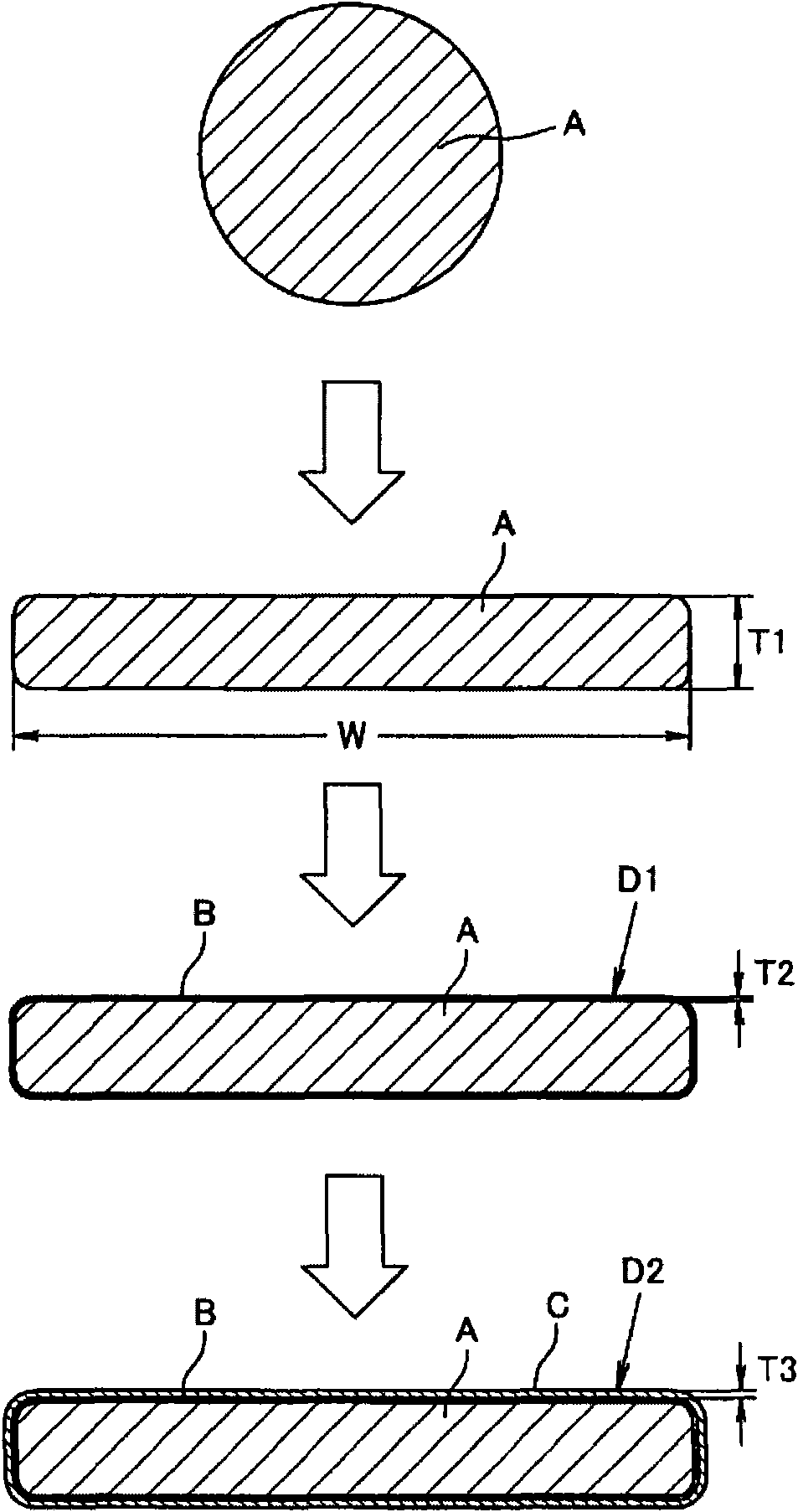

[0086] figure 1 The manufacturing method of the insulated wire D2 which concerns on one Embodiment of this invention, and its manufacturing apparatus are shown. The main of which image 3 Manufacture of the illustrated insulated wire D2 will be described, and the description will also refer to a modified example. Figure 4 The manufacture of insulated wire D2.

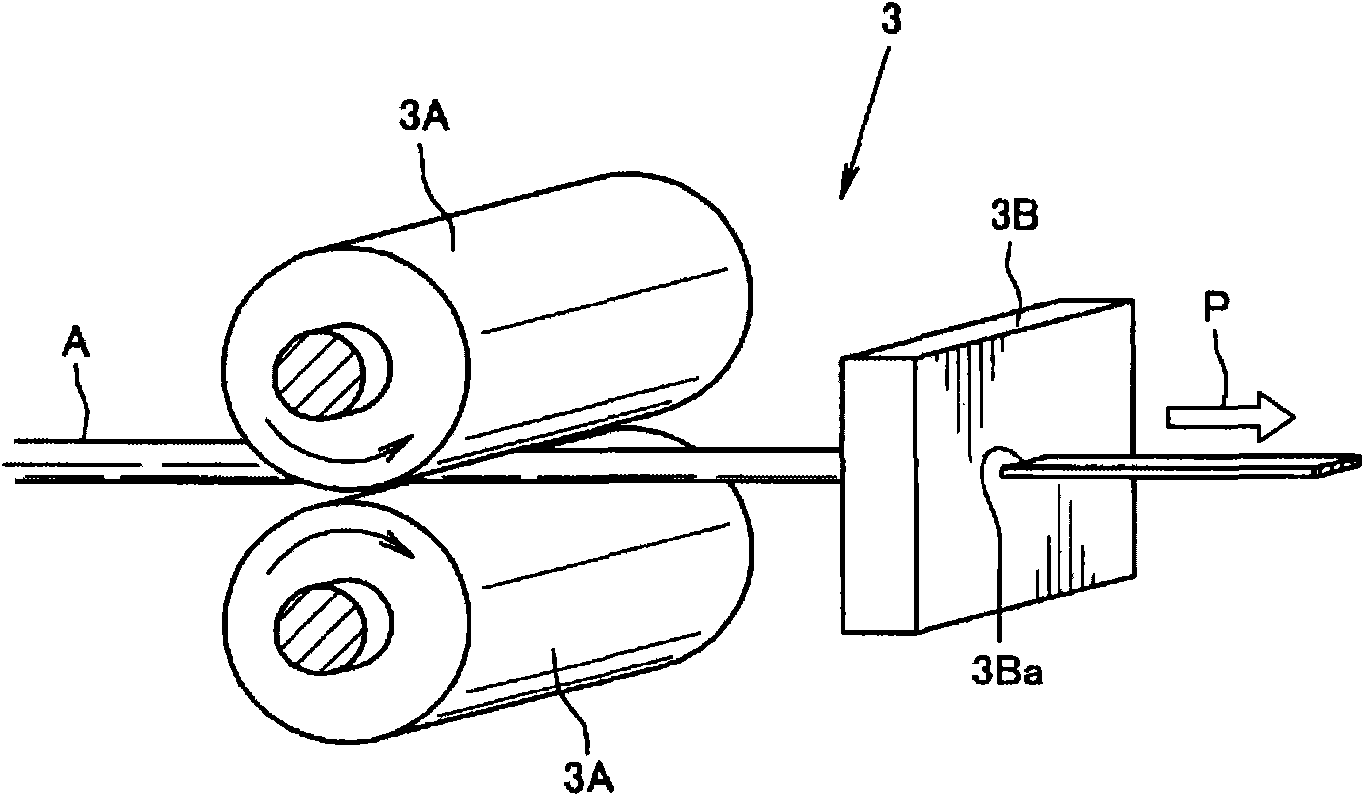

[0087] like figure 1 As shown, the manufacturing apparatus 1 for manufacturing the insulated wire D2 is sequentially arranged in a tandem manner: a conductor supplying part 2 in a conductor supplying step a, a conductor processing part 3 in a conductor processing step b, a conductor annealing part 4 in a conductor annealing step c, a film Film baking section 5 in baking step d, pulling section 6 after film baking section 5, wire preheating section 7 in wire preheating step e, wire straightening section 8 in wire straightening step f, resin extrusion step The resin extrusion part 9 of g, the electric wire cooling p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| section shrinkage | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com