Automatic monitoring system of tobacco-leaf bulk curing barn

An automatic monitoring system and intensive curing room technology, applied in control/regulation system, non-electric variable control, tobacco, etc., can solve the problems of reducing yellow smoke rate, wasting energy, and wasting electric energy, so as to improve the quality of baking and realize reasonable Effects of using and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

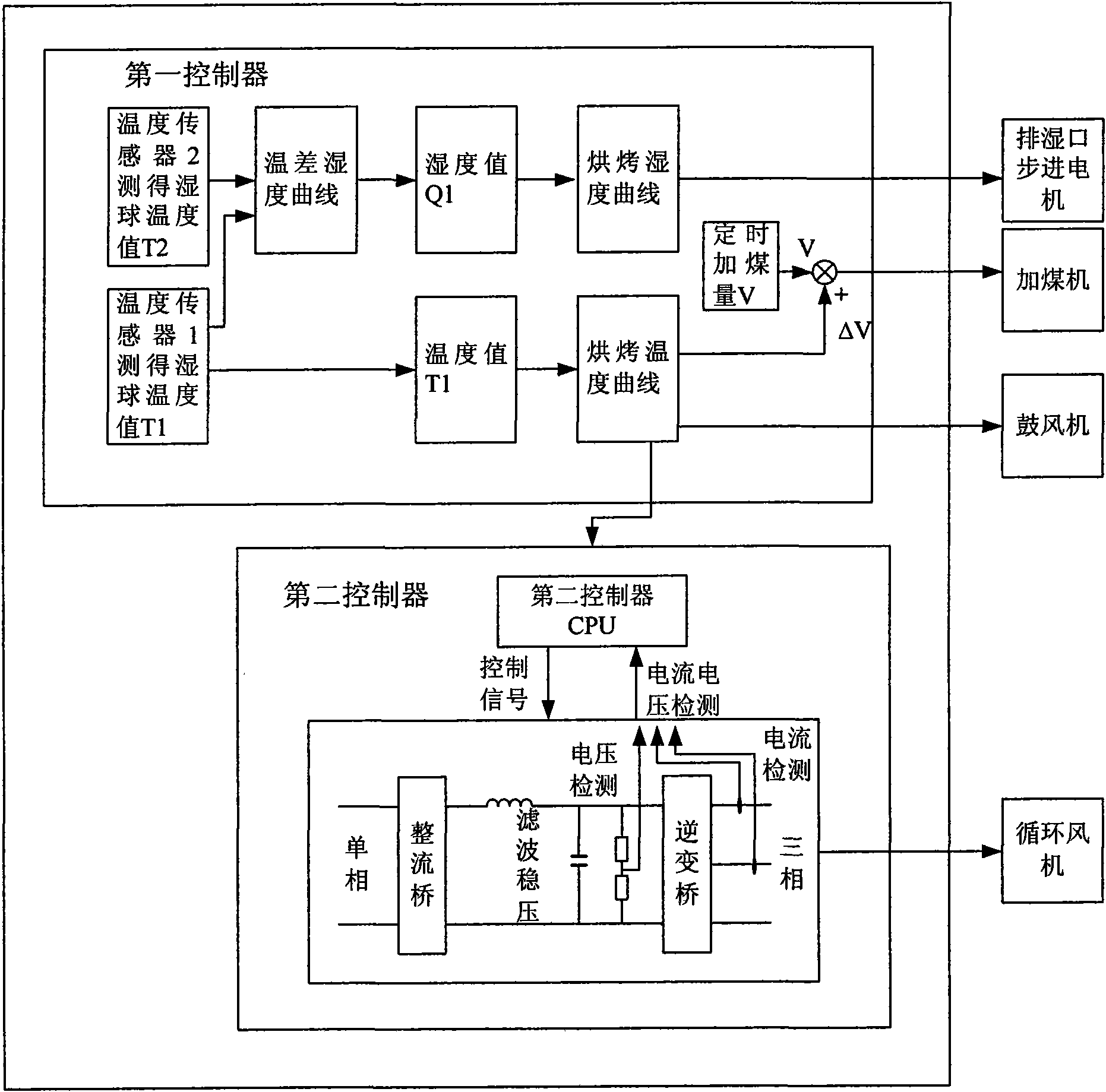

[0017] see below figure 1 The present invention will be described in detail.

[0018] The first controller is the main controller, which controls the coal stoker, the air blower, the stepping motor of the moisture outlet, and sends the circulating fan control signal to the second controller.

[0019] In the first controller, the temperature difference-humidity curve of the dry bulb temperature and the wet bulb temperature, the baking humidity curve and the baking temperature curve are preset. Taking the beginning of a flue-cured tobacco cycle as the timing starting point, at time t, the temperature sensor measures the dry bulb temperature T1 and the wet bulb temperature T2 respectively.

[0020] After comparing the temperature difference between T1 and T2 with the temperature difference-humidity curve, the barn humidity Q1 is obtained. Compare the humidity value Q1 with the humidity value Q at time t in the preset baking humidity curve. When Q1>Q, control the stepping motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com