Device and method for testing linear reciprocating sliding friction and abrasion

A technology of sliding friction and testing equipment, which is applied in the field of wear and friction, and can solve problems such as the inability to achieve a straight line at a constant speed, reciprocating relative sliding wear, difficulty in measurement, and small wear surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

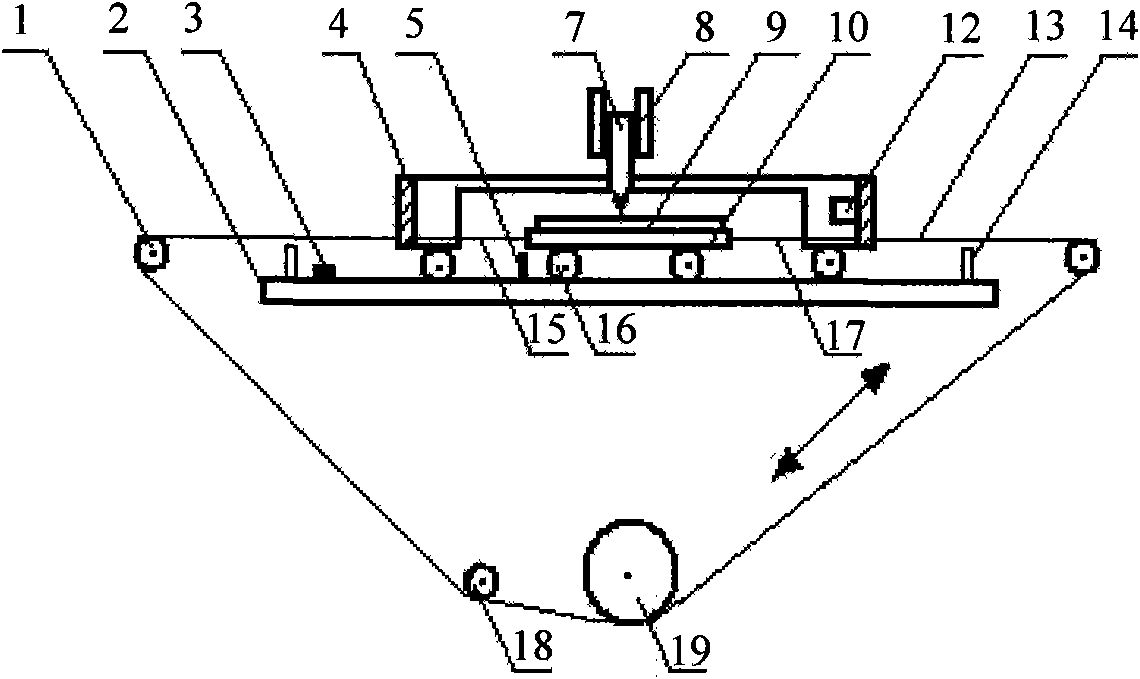

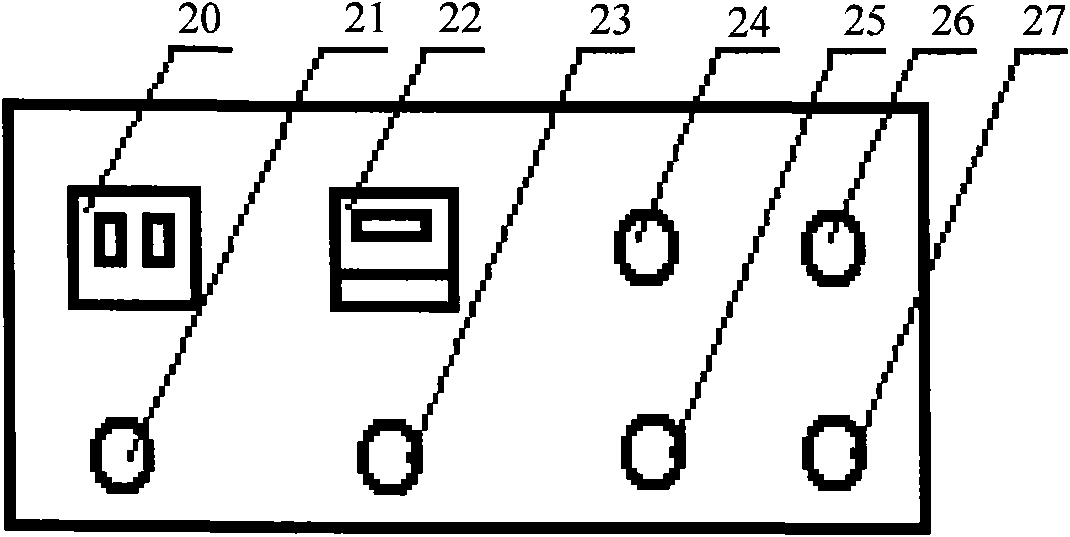

[0029]Start the inverter and set the walking speed. Install the sample 9, open the locking device 5 of the sample table 10, and connect the drag frame and the sample table 10 with steel wire ropes 13, 15, 17. Put the friction block 7 on the sample 9. Set the wear cycle on the counter 22, start the motor, and carry out the wear test. After a certain period of wear, the test piece or wire is evaluated.

Embodiment 2

[0031] Start the inverter and set the walking speed. Install the sample, disconnect the workbench from the drag frame, and lock the sample stage 10. Put the slider 6 on the sample 9, and connect the slider 6 and the tension sensor 12 with a light-weight high-strength wire 11 . Start the peak hold instrument 21, start the motor, and measure the maximum static friction force and sliding friction coefficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com