Gasification circulation thermal power system of mild-hypothermia thermal source

A sub-low temperature, thermal power technology, used in engine components, combustion engines, machines/engines, etc., can solve problems affecting system cycle efficiency, and achieve the effect of reducing operating costs, improving thermal efficiency, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

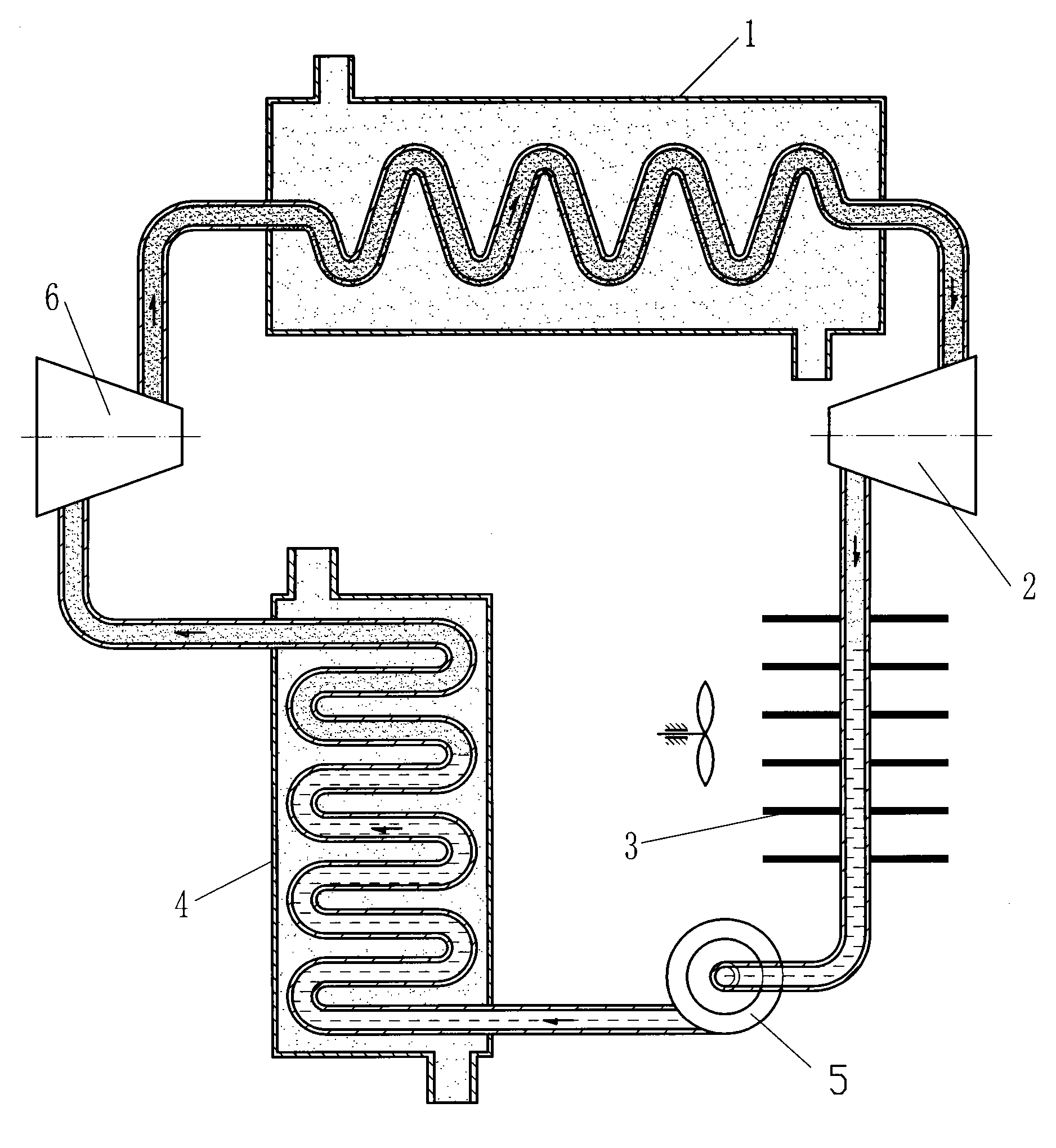

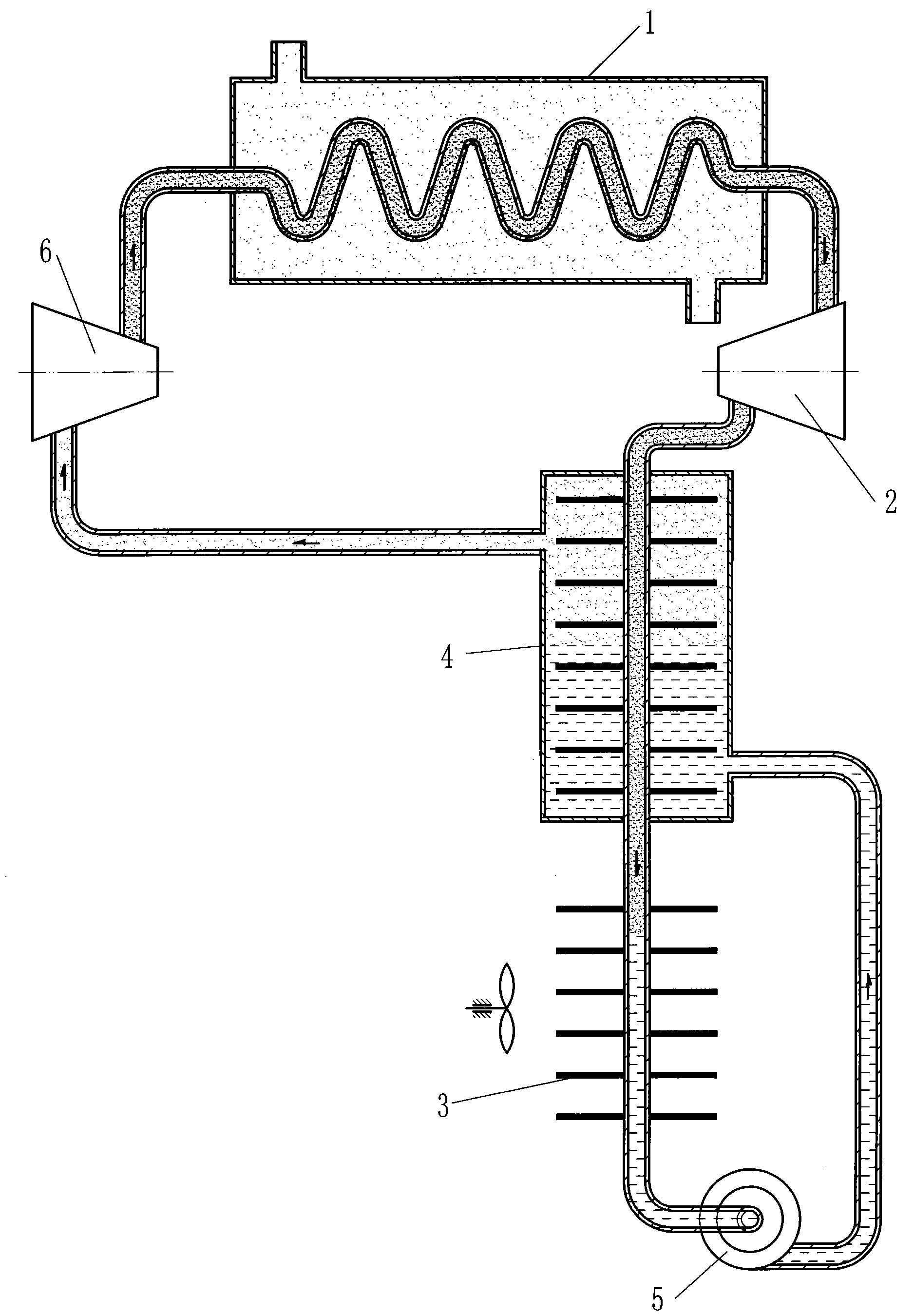

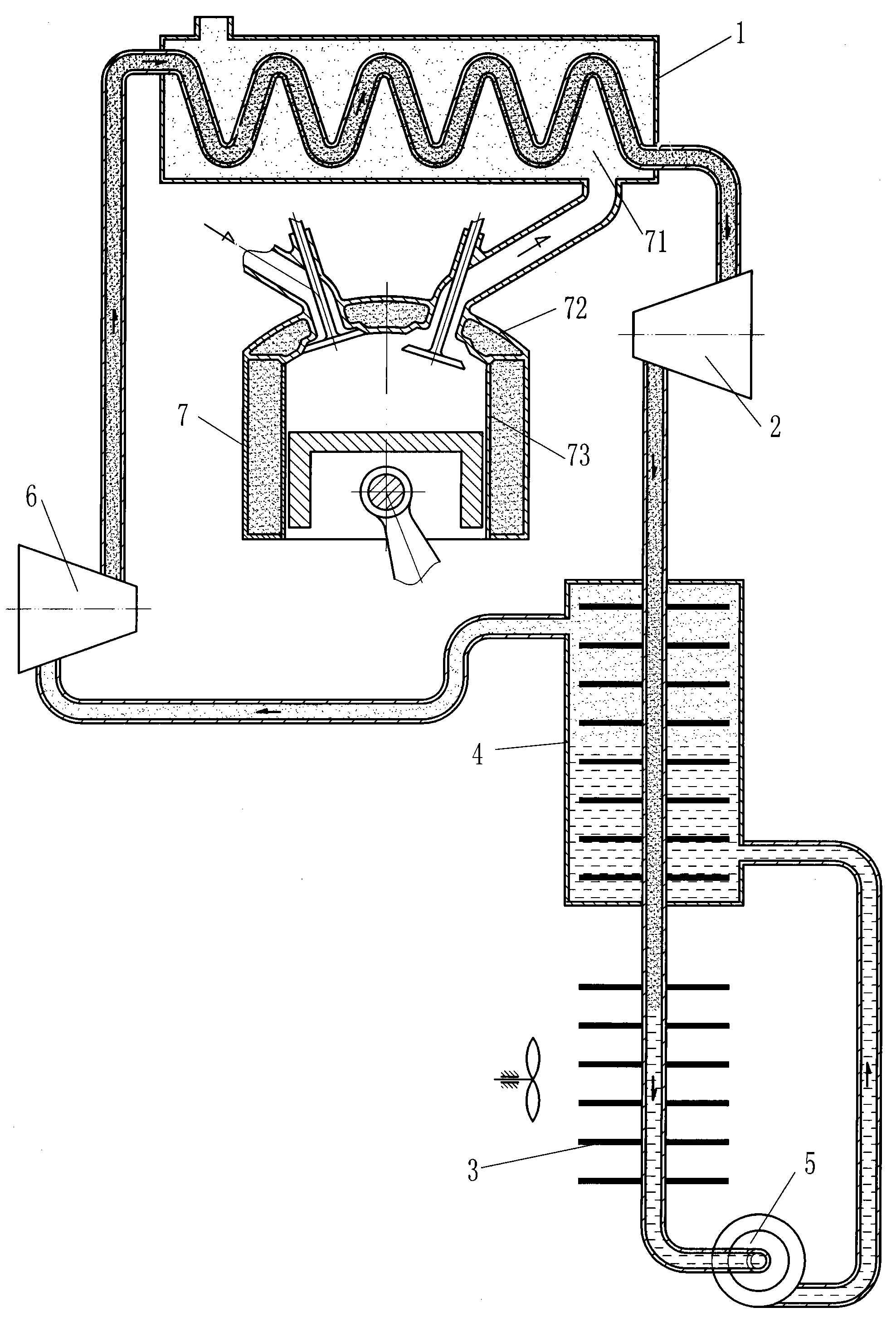

[0018] Figure number

[0019] 1. High temperature heat source 2. Power machine 3. Condensing cooler

[0020] 4. Sub-low temperature heat source 5. Liquid-phase working medium booster pump 6. Gas-phase working medium return booster pump

[0021] 7. Internal combustion engine 71. Exhaust gas 72. Cylinder head 73. Cylinder liner

[0022] Please refer to figure 1 The shown sub-low temperature heat source gasification cycle thermodynamic system includes a high temperature heat source 1, a power machine 2, and a condensation cooler 3. The working medium outlet of the high temperature heat source 1 is connected to the working medium inlet of the power machine 2, and the power machine 2 The working fluid outlet of the condensing cooler 3 is connected to the working fluid inlet of the condensing cooler 3, and the working fluid outlet of the condensing cooler 3 can be directly or through the liquid-phase working fluid booster pump 5 and the heated working fluid inlet of the sub-low te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com