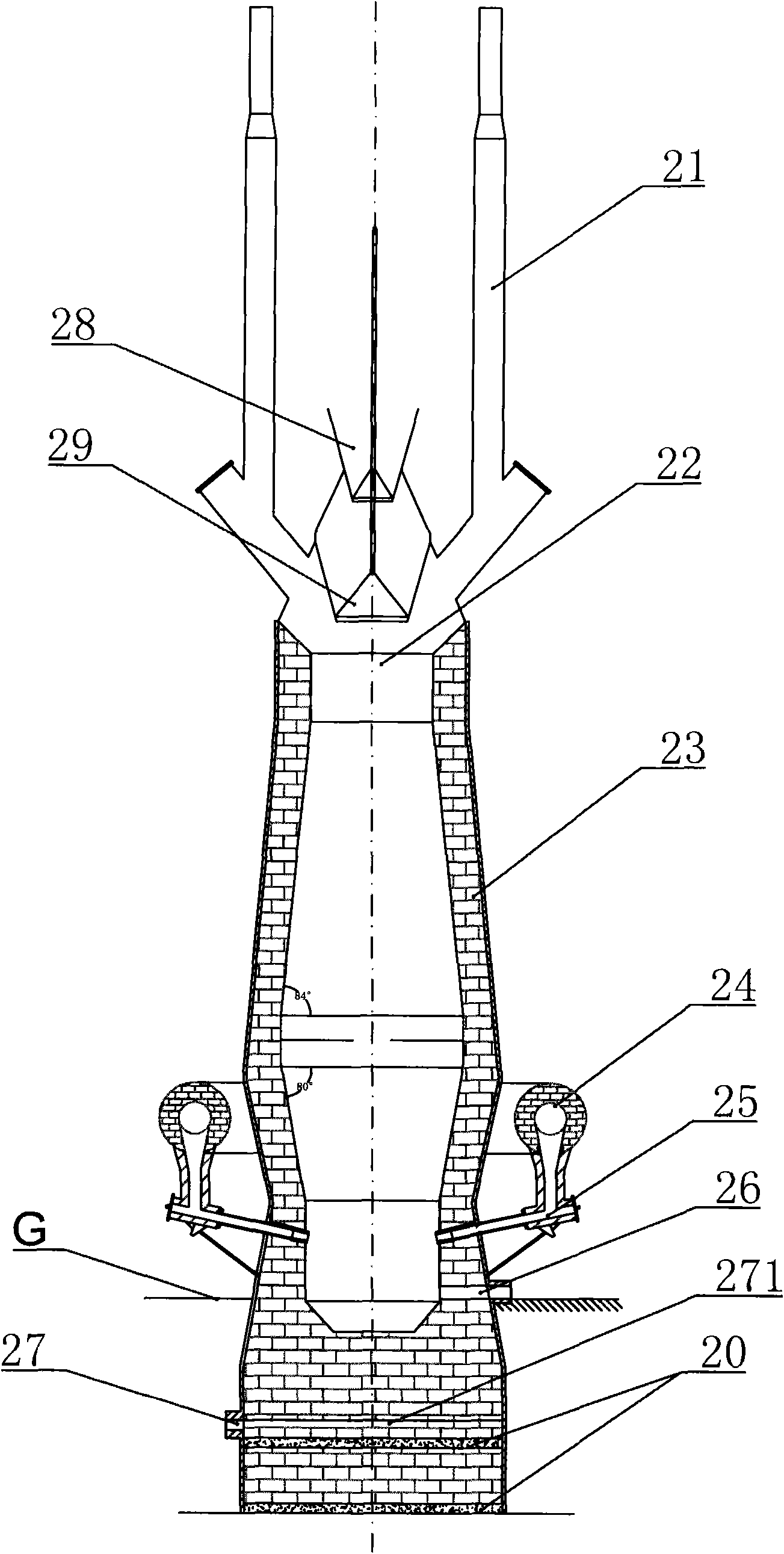

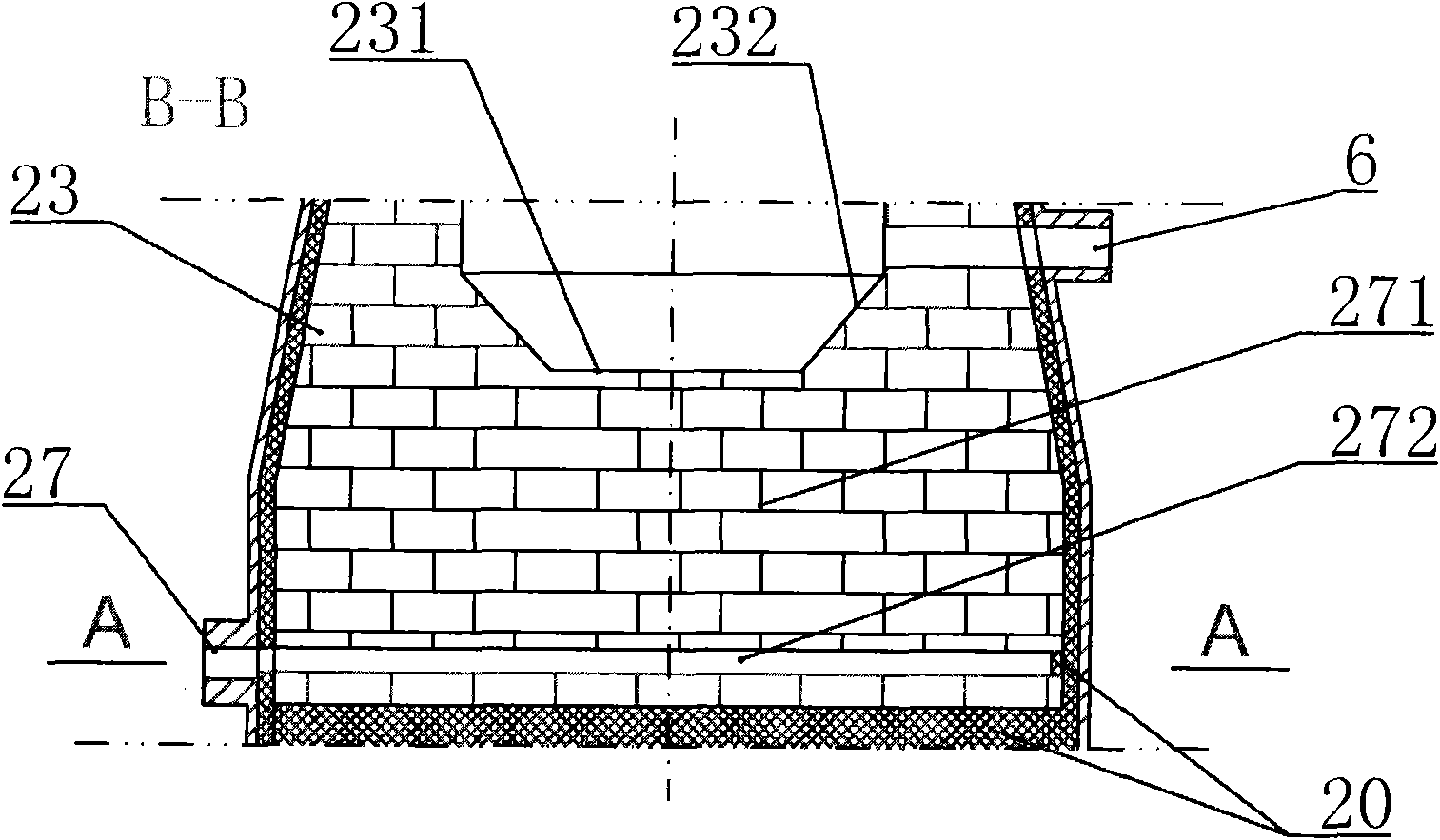

Smelting process for rich manganese and equipment thereof

A smelting method and enrichment technology, which is applied in the integrated smelting field of enrichment and diversification of low-manganese ferroalloys, can solve the problems of increasing investment, reducing production efficiency, and damage to the bottom of the furnace body, so as to achieve full utilization of resources and economic benefits Remarkable, productivity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The main content of raw material manganese ore is shown in Table 1:

[0037] Table 1

[0038] Content (weight%)

[0039] Among them, A is the Tongling block, B is the Tongling block, C is the South African block, and D is the Indian powder. Manganese ore with the following weight ratio: 30% of A, 20% of B, 30% of C, and 20% of D are configured into mixed ore, and the Mn content in the obtained mixed ore is 17.5%, and the Fe content is 35.7%. These four kinds of manganese ores are processed into 20-40mm particle size.

[0040] And according to CaO / SiO 2 =0.35, then it is necessary to add 2.43Kg of quicklime containing 90% CaO to 100Kg of mixed ore to obtain a mixture. The particle size of quicklime is 3-10mm.

[0041] The coke is first-grade coke (ash content 12-12.5), and the particle size is processed to 25-50mm.

[0042] 1350Kg of the above-mentioned mixture and 450Kg of coke are added into the reaction furnace of the present invention. The oxygen-cont...

Embodiment 2

[0065] The main content of raw material manganese ore is shown in Table 4:

[0066] Table 4

[0067] Content (weight%)

mn

Fe

CaO

SiO 2

Pb

Zn

First

33.6

23

0.3

3.6

0.58

0.3

Second

5

45

0.84

11.2

0.6

0.8

[0068] Among them, A is the Australian block, and B is the Tongling block. Manganese ore in the following weight ratio: A 55% and B 45% are configured into a mixed ore, and the Mn content in the obtained mixed ore is 20.73%, and the Fe content is 32.9%. These two manganese ores are processed to a particle size of 20-40mm.

[0069] And according to CaO / SiO 2 =0.35, then it is necessary to add 2.25Kg of quicklime with a CaO content of 85% to 100Kg of mixed ore to obtain a mixture. The particle size of quicklime is 3-10mm.

[0070] The coke is first-grade coke (ash content 12-12.5), and the particle size is processed to 25-50mm.

[0071] Add 1400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com