Paint-free abrasion resistant veneer and preparation technique thereof

A decorative panel and one-sided technology, which is applied in the field of decorative panel manufacturing, can solve the problems of increased difficulty in meeting the requirements of environmentally friendly products, increased work environment pollution, and inability to increase production, so as to omit gluing equipment, save air pollution, and improve The effect of product quality and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

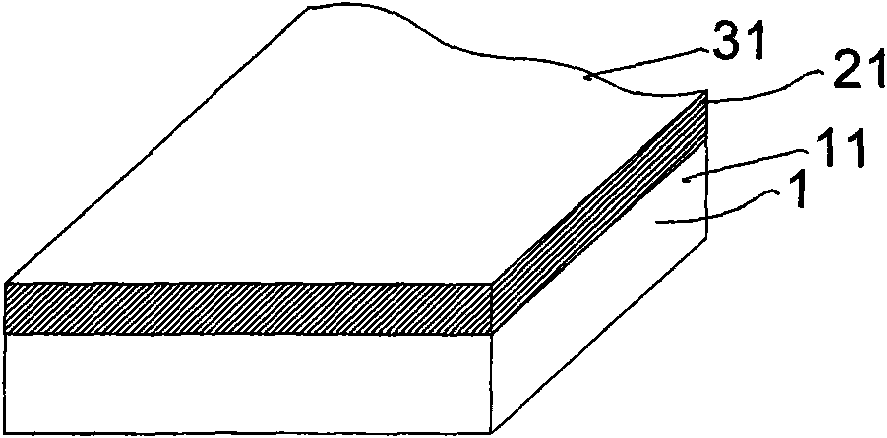

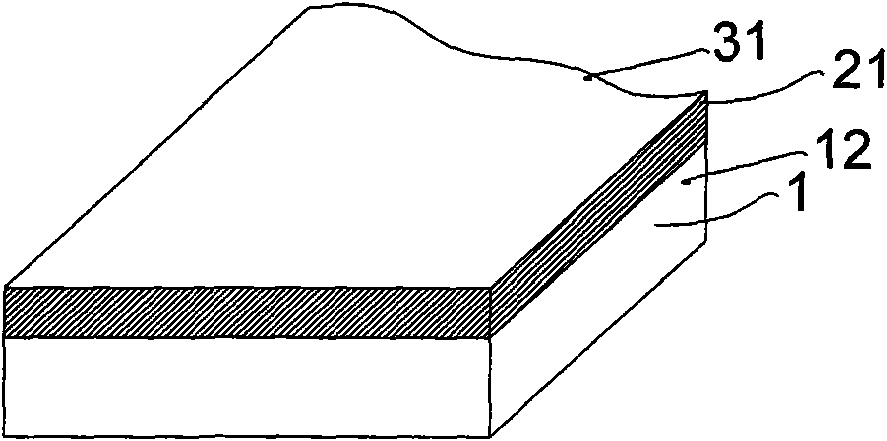

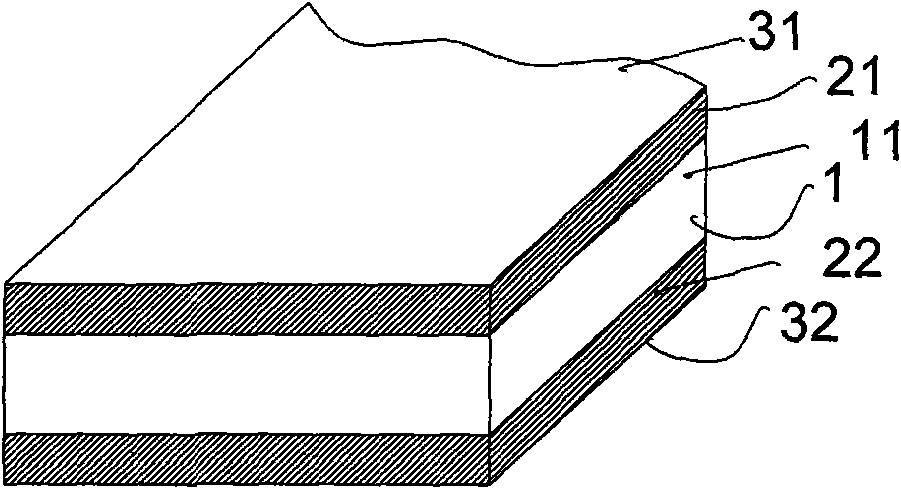

[0025] Such as Figure 1 to Figure 5 In the shown embodiment, reference numerals illustrate: substrate layer 1 , plywood layer 11 , woodworking board layer 12 , first surface layer 21 , second surface layer 22 , first aluminum oxide layer 31 , second aluminum oxide layer 32 .

[0026] Embodiments 1 and 2 The paint-free wear-resistant decorative panels include a base material layer 1 , and a first surface layer 21 is bonded to one side of the base material layer 1 . The substrate layer 1 includes a plywood layer 11 and a wood board layer 12 with a moisture content below 10 after constant thickness sanding and smooth surface. The first surface layer 21 is the first adhesive film base paper made by soaking the decorative paper of pattern and color, a series of ecological and natural wood grain colors and plain colors through the melamine resin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com