Surface transverse wave pressure and temperature sensor

A technology of temperature sensor and surface shear wave, which is applied in the field of device in the field of sensor technology, can solve the problems of reducing the volume of the sensor, and achieve the effects of improving strain sensitivity, increasing stress concentration effect, and improving resolution and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

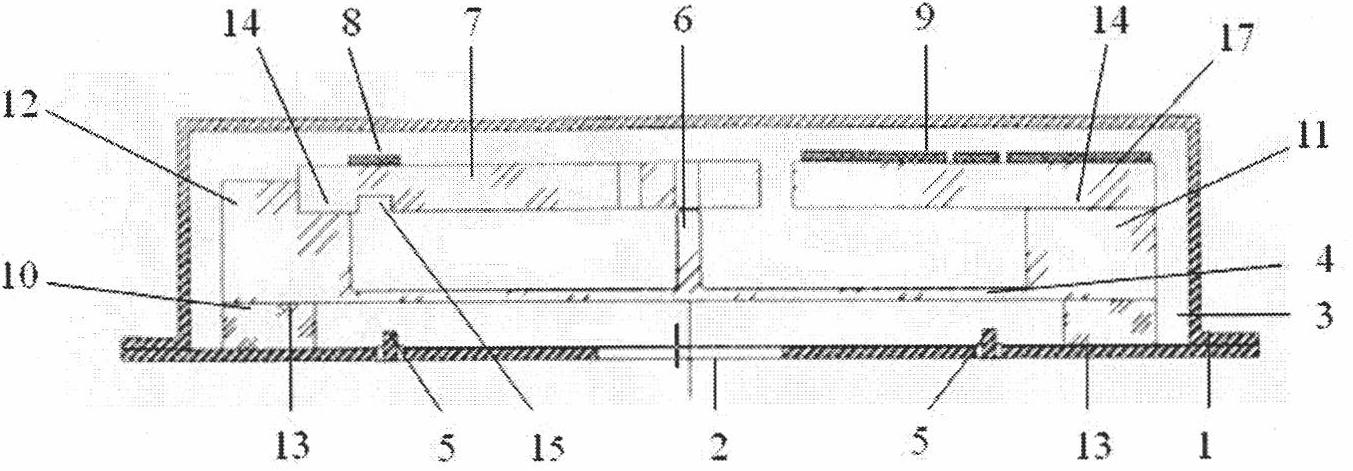

[0025] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment is carried out under the premise of technical solution of the present invention, has provided detailed implementation mode and specific operation process, but protection scope of the present invention is not limited to the following the embodiment.

[0026] Such as figure 1 As shown, this embodiment includes: a metal base 1, a tube cap 3, a glass diaphragm 4, a glass ring 10, a quartz crystal cantilever beam 7, a resonant surface shear wave force sensor 8, a quartz crystal plate 17 and a resonant surface shear wave The temperature sensitive element 9 is provided with a glass ring 10 on the metal base 1 , the glass ring 10 is concentric with the pressure inlet 2 of the metal base 1 , and the measured pressure can be transmitted to the glass diaphragm 4 through the glass ring 10 . A glass diaphragm 4 is arranged on the glass ring 10. There ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com