Improving method of belt porch

A technology of belt corridors and steel corbels, applied in the direction of building construction, building maintenance, industrial construction, etc., can solve the problems of loss, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

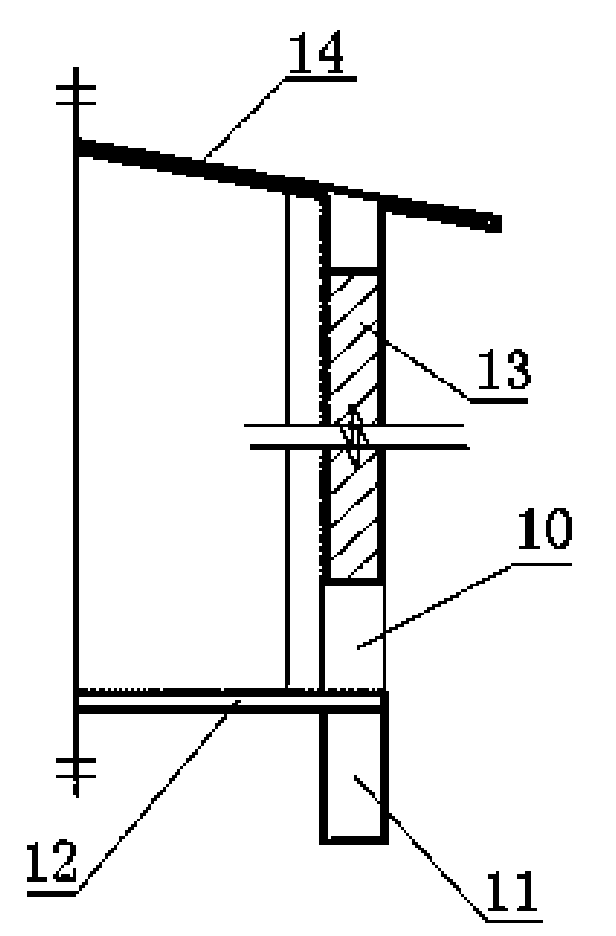

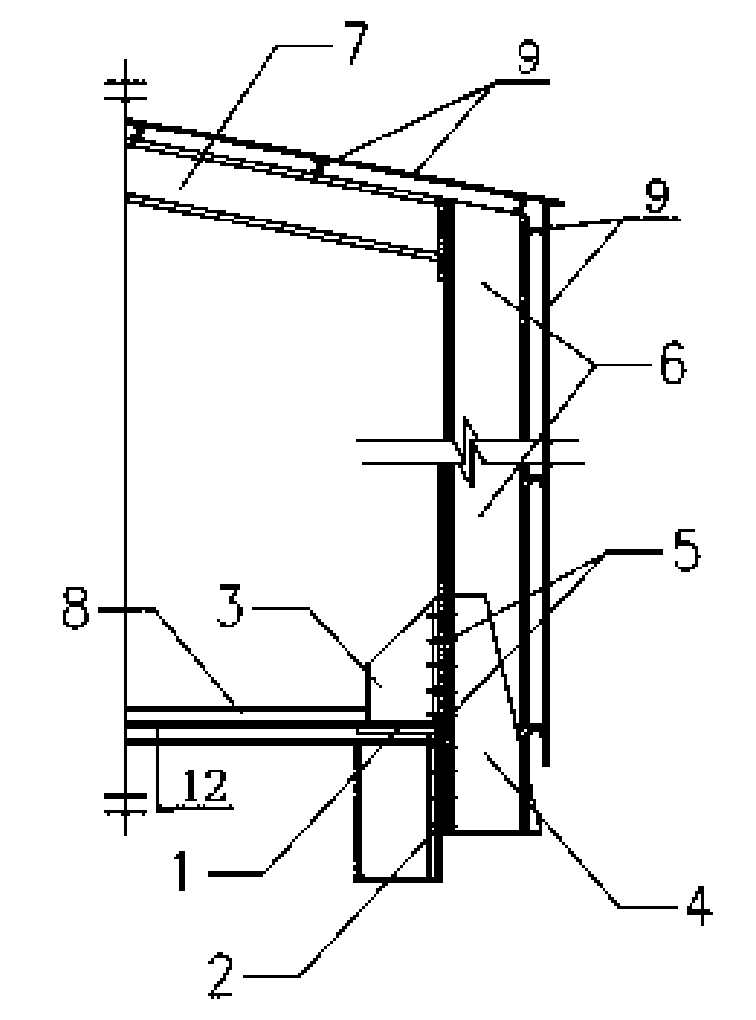

[0012] Embodiment: first make a gap 10 at the cornice every 3 meters and the brick wall near the floor of the enclosure structure on both sides of the original belt corridor, and weld the steel plate 1, 2. Weld the steel corbel 3 and the steel plate 1 on three sides, then connect the steel shoe foot 4 with the steel plate 2 and the steel corbel 3 with high-strength bolts 5, first weld the steel column 6 and the steel beam 7 on the site, Hoisting to the top of the original belt gallery 12 again, the bottom edge of the steel column 6 and the steel boot pin 4 is welded on three sides, and then the surface layer 8 is made on the original belt gallery 12. The other side is symmetrical with this, and finally the middle parts of the steel beams 7 on both sides are welded, and the enclosure brick walls 13 and roof panels 14 of the original belt corridor are removed one by one according to the procedure, and the purlins 9 and colored profiled steel plates 9 are gradually laid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com