Method for synthesizing propylene glycol methyl ether

A technology for propylene glycol monomethyl ether and a synthesis method, which is applied in chemical instruments and methods, ether preparation, ether preparation by alkylene oxide, etc., can solve the problems of low catalyst activity, high reaction temperature, low selectivity, etc., and achieves short reaction time. , the effect of mild reaction conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

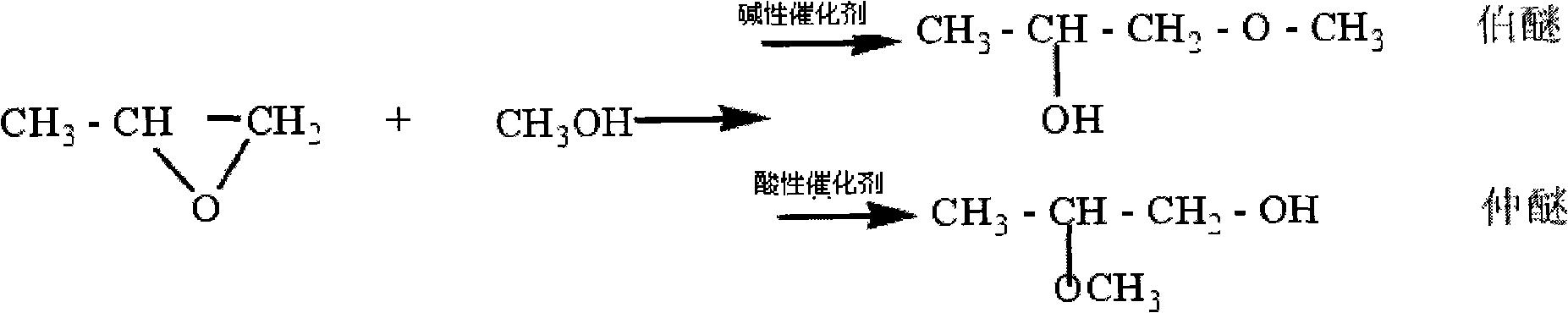

Method used

Image

Examples

specific Embodiment approach 1

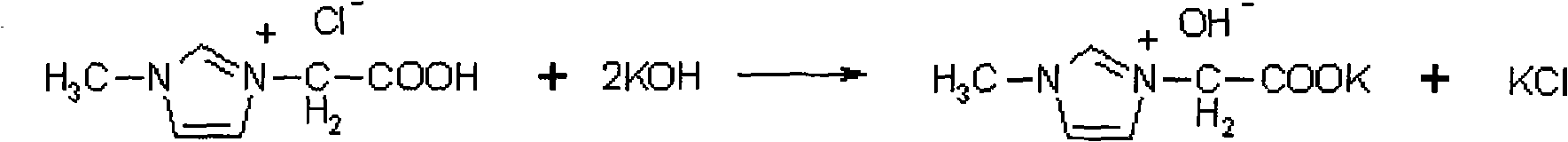

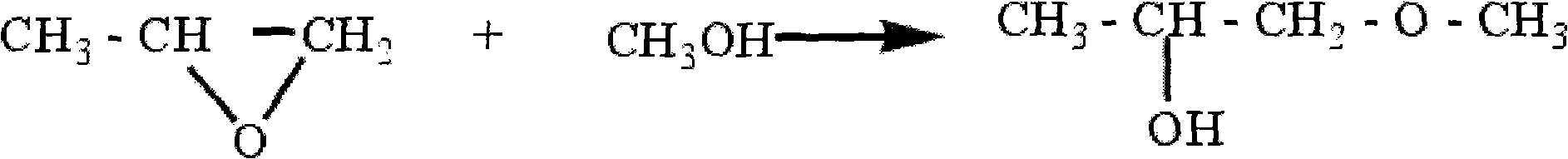

[0007] Specific embodiment one: the synthetic method of propylene glycol monomethyl ether of this embodiment is realized according to the following steps: one, the amount of substance is 0.5~0.6mol, the volume is the anhydrous methanol of 20~24.3mL, and the amount of substance is 0.015~0.025 mol, propylene oxide with a volume of 1.05-6mL and a catalyst with a substance amount of 0.004-0.02mol are uniformly mixed to obtain a mixed solution A; 2. Heat the mixed solution A to 60-70°C in a water bath, and magnetically stir for 3-5 hours , to get mixed solution B; 3. After the mixed solution B is naturally cooled to room temperature, carry out normal pressure distillation, so that the solvent in the mixed solution B is all steamed out to obtain propylene glycol monomethyl ether; wherein the catalyst in step 1 is acetate Hydroxyl methylimidazolium hydroxide, or ionic liquid composed of methylimidazolium acetate chloride and ferric chloride in a molar ratio of 1:1-3.

[0008] The che...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the amount of anhydrous methanol in step 1 is 0.52-0.58 mol and the volume is 21-23 mL. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment differs from Embodiment 1 in that the amount of anhydrous methanol in step 1 is 0.56 mol and the volume is 22 mL. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com