Automobile steering-by-wire redundancy and fault tolerance system and control method

A technology of steering system and automobile line, applied in the direction of automatic steering control parts, steering mechanism, steering rod, etc., can solve the problems of low efficiency, failure to consider the practical application of CAN communication, and complicated design process, etc., and achieve high industrialization benefits, The effect of real-time communication performance optimization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

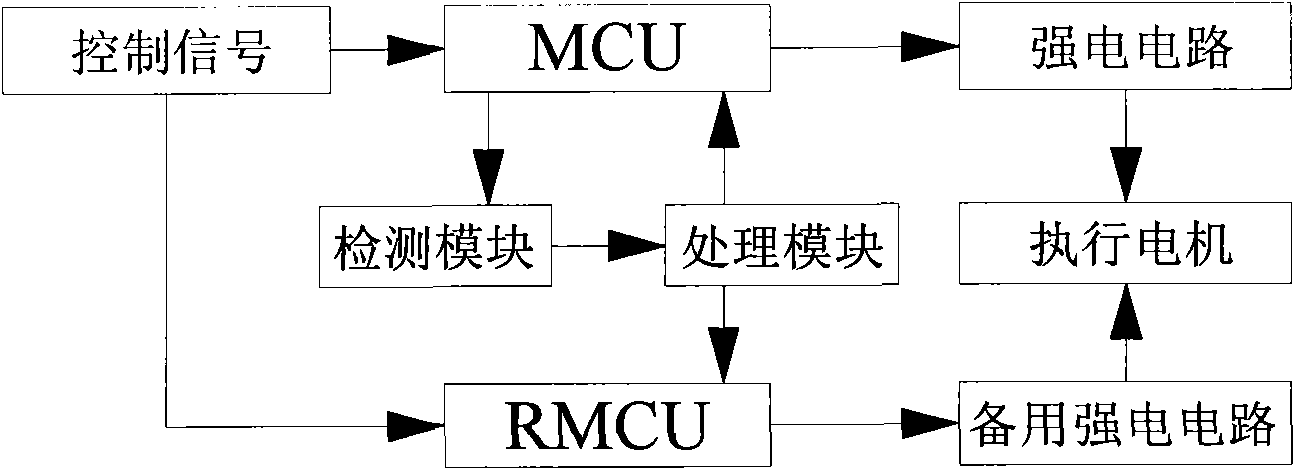

[0029] figure 1 The automotive steer-by-wire system with redundant and fault-tolerant structure of the present invention is shown.

[0030] exist figure 1 middle:

[0031] MCU: the main control chip of the steer-by-wire system;

[0032] Detection module: mainly includes the watchdog module;

[0033] Processing module: According to the information of the detection module, shield the main control chip MCU, and start the backup chip RMCU and its backup circuit. The processing module also includes conventional sensor input modules, rotation angle sensors, torque sensors, current sensors, line displacement sensors, vehicle speed sensors etc.

[0034] RMCU: spare chip for steering-by-wire system;

[0035] Backup strong current circuit: the backup motor drive circuit of the steer-by-wire system. The circuit has the function of automatically detecting the temperature and current of the motor. When the motor is overheated and overcurrent, it actively feeds back the signal to the R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com