High-efficiency multi-use pipe cutting machine

A pipe cutting machine, high-efficiency technology, used in pipe cutting devices, shearing devices, metal processing machinery parts, etc., can solve the problems of low efficiency and high labor intensity, achieve convenient and flexible use, scientific structure design, continuous automatic cutting Effects of pipes or profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

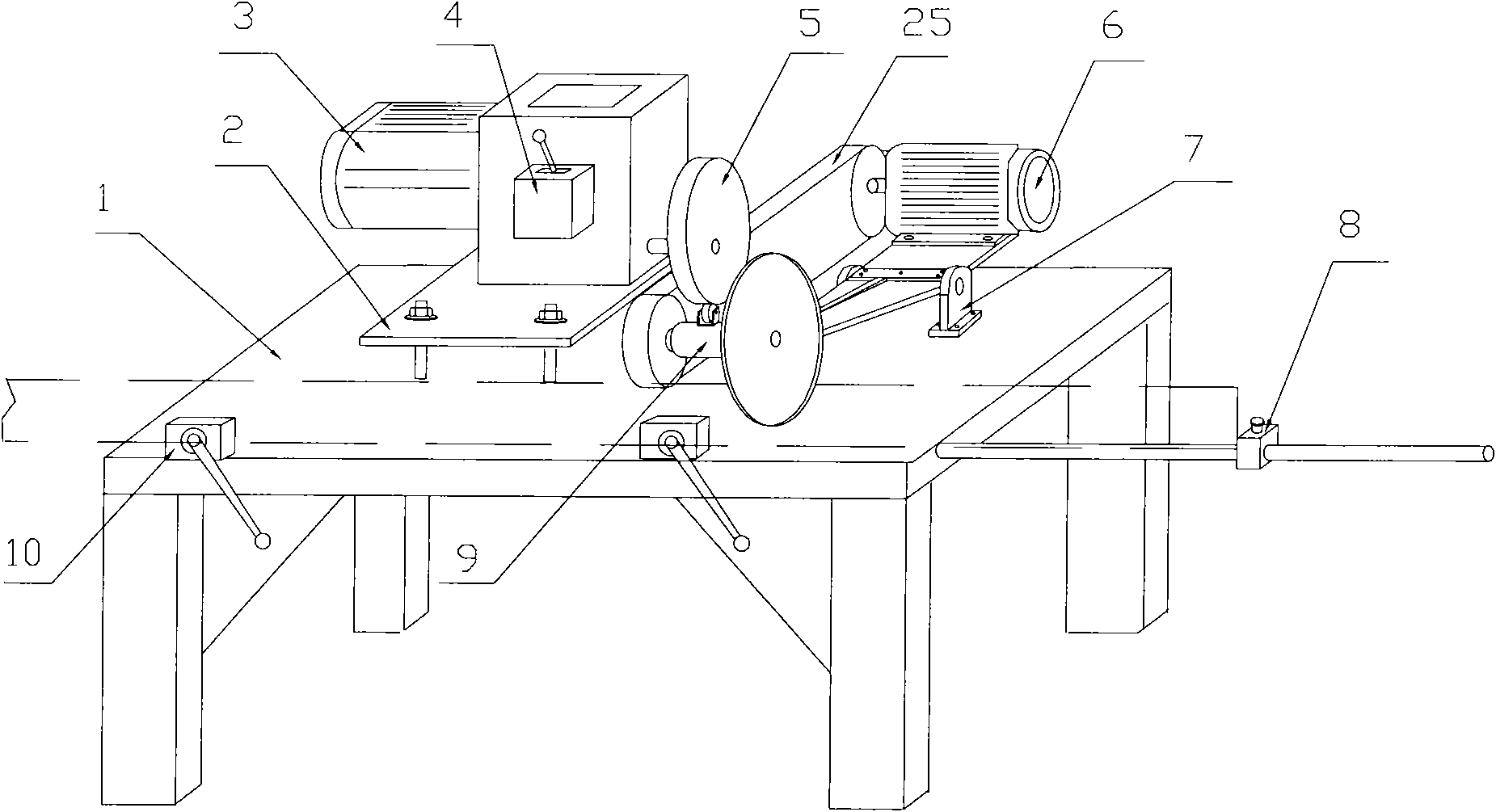

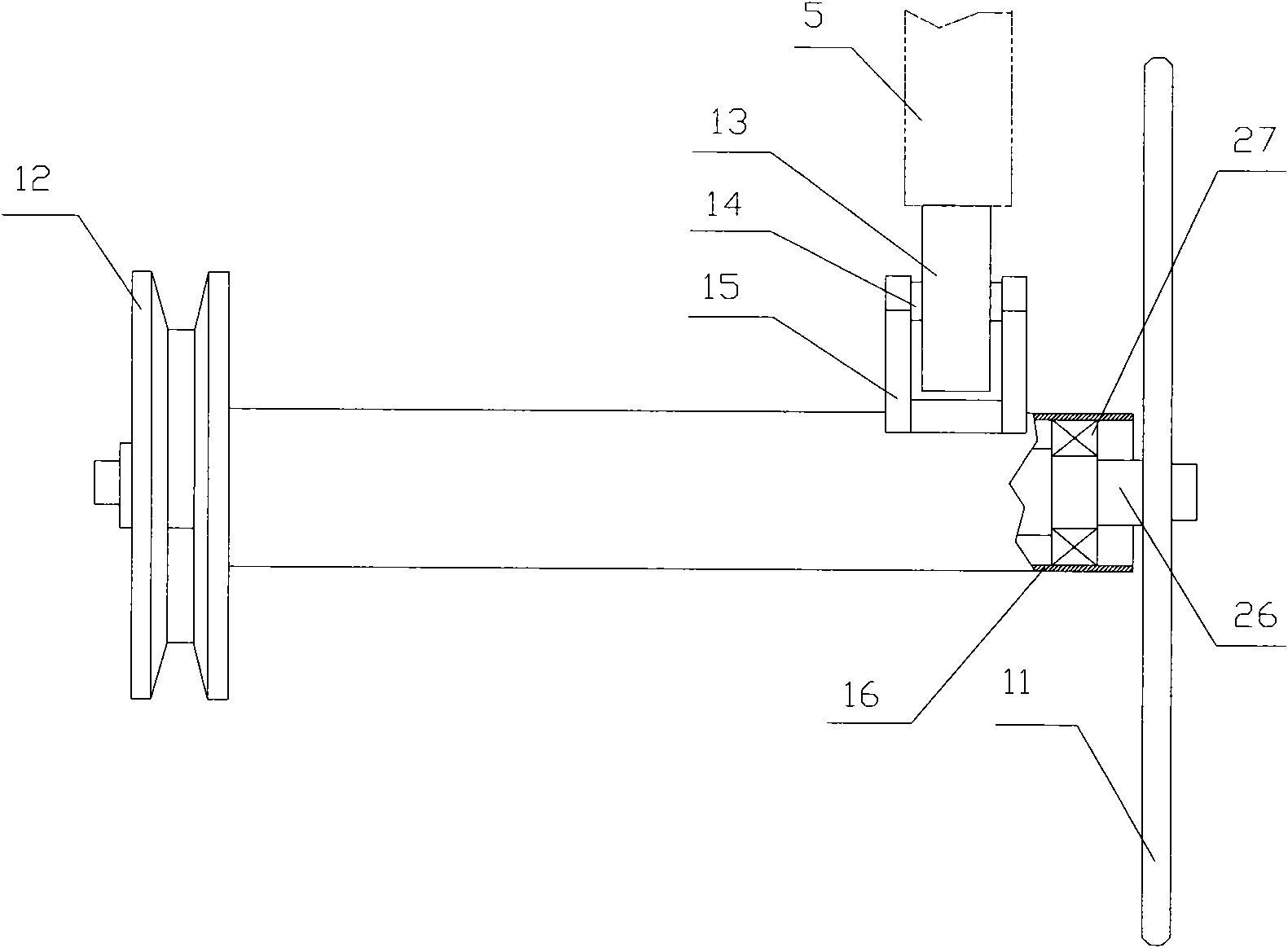

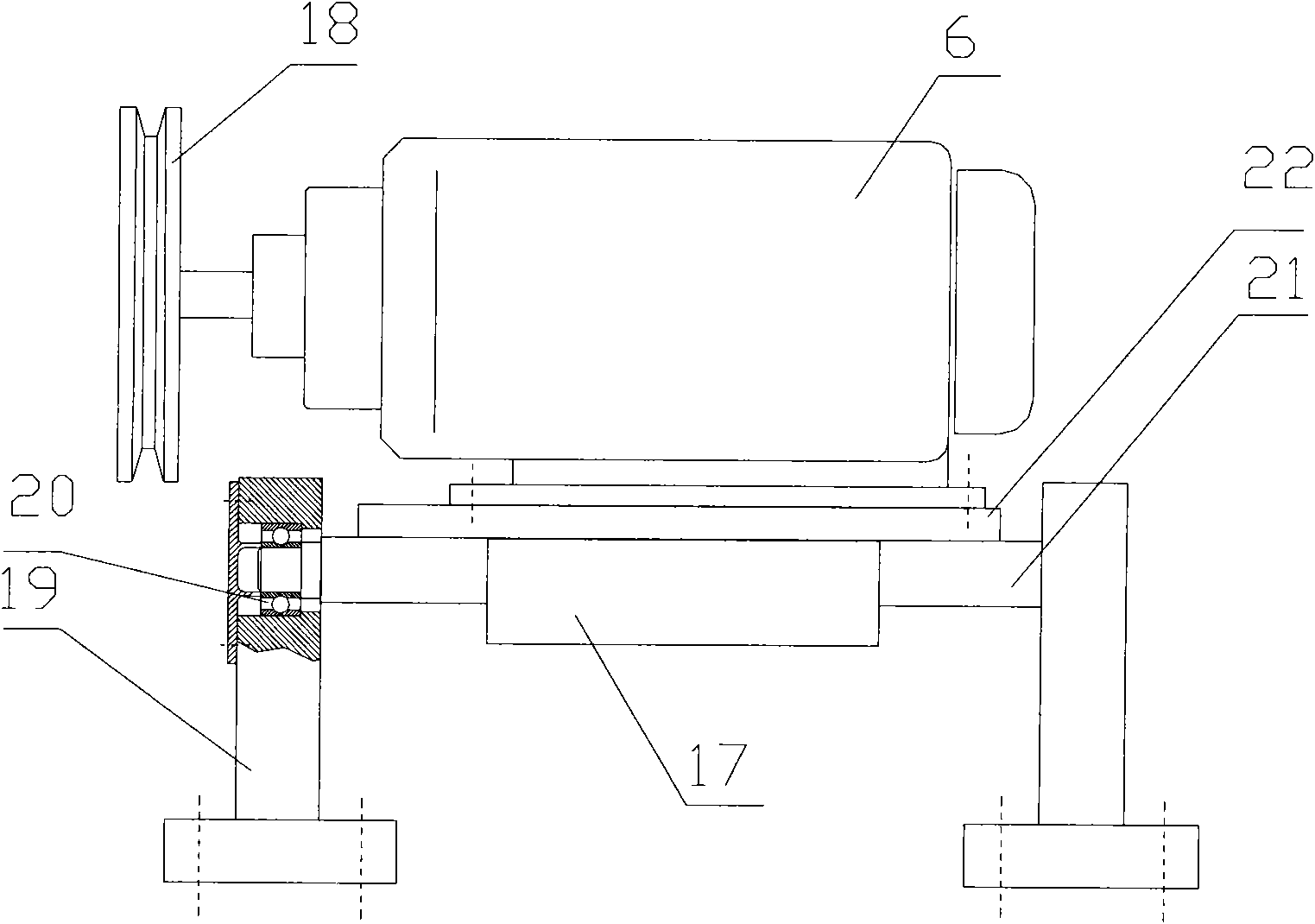

[0023] see figure 1 , 2 . 7), positioning system (8), spindle device (9), clamping device (10).

[0024] First, we install the geared motor (3) on the geared motor base (2) and fix it on the base frame (1). The motor can be a speed-adjustable motor, and the cam (5) is installed on the output shaft of the geared motor (3). , connected with a key, the governor (4) and the geared motor (3) are connected together, the output shaft of the geared motor (3) should be parallel to the main shaft device (9) when installed, and the governor (4) Adjust the rotating speed of the output shaft of geared motor (3), can control the rotating speed of cam (5), also just can control the up and down speed of main shaft device (9), has exactly controlled cutting material speed.

[0025] Then we fix the rocking shaft sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com