System for treating waste gas generated by automotive internal decorative board

A technology for automotive interior panels and exhaust gas treatment, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., and can solve the problem of failure to effectively treat organic pollutants in exhaust gas, low removal efficiency of organic pollutants, and failure to meet emission standards and other issues to achieve the effect of lowering the temperature, lowering the price and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

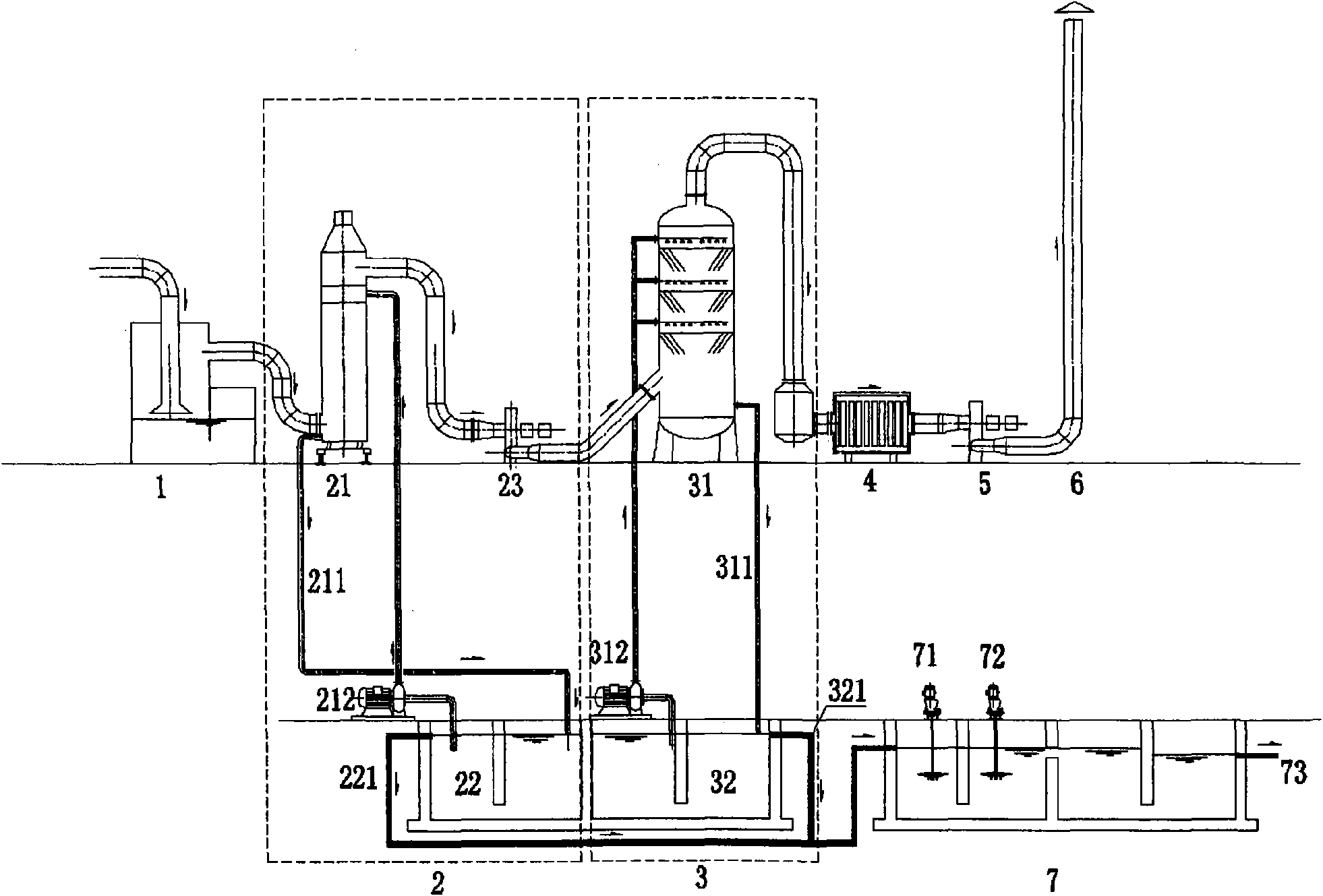

[0027] As shown in the drawings, the process flow device of the present invention consists of an impingement hydraulic leaping dust removal system 1, a cyclone water film dust removal system 2, a chemical absorption system 3, an adsorption system 4, an induced air system 5, a high-altitude discharge system 6 and residual water purification treatment The system consists of seven parts.

[0028] The present invention will be further described in detail with reference to the accompanying drawings.

[0029] An exhaust gas treatment system for the production of automotive interior panels, which in turn consists of the following parts:

[0030] (1) Impact hydraulic jump dust removal system 1: In the impact hydraulic jump dust removal system 1, the momentum of the particle pollutants and the gas is different by the sudden drop in the flow rate after the exhaust gas enters, so that the particle pollutants and the gas are separated, and the gas is affected. The water surface reflects upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com