Image forming apparatus

An image and toner image technology, applied in the field of image forming devices, can solve the problems of small magnetic shielding, inability to adapt to size, and redundant space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0066] Details of the fixing unit

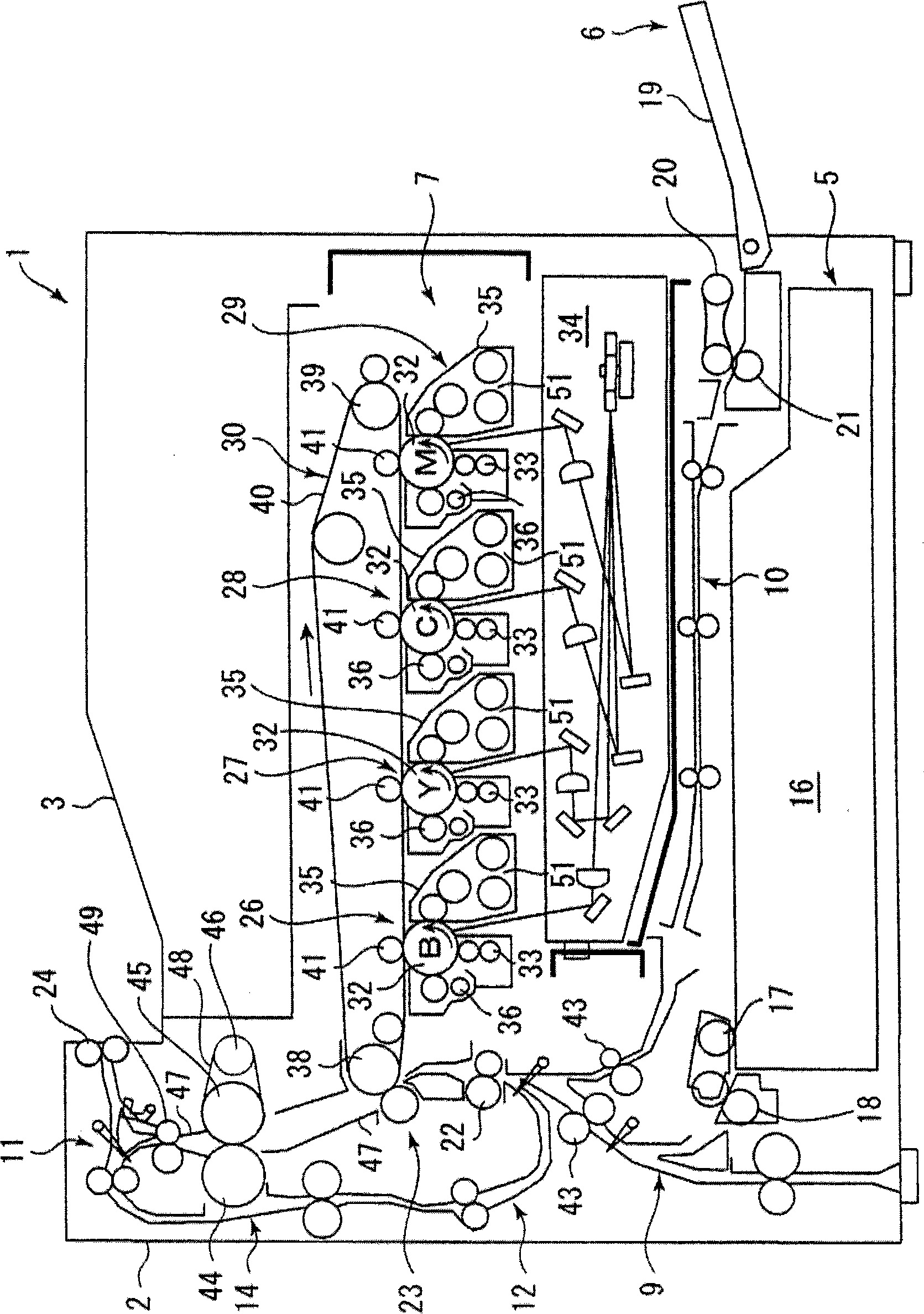

[0067] The fixing unit 14 used in the first embodiment of the image forming apparatus 1 will be described in detail below.

[0068] figure 2 is a longitudinal sectional view showing an example of the structure of the fixing unit 14 . exist figure 2 Middle indicates a state where the fixing unit 14 mounted on the image forming apparatus 1 is rotated about 90 degrees in the counterclockwise direction. Thus, in figure 1 The paper feed direction extending from bottom to top in figure 2 from right to left. In addition, in the case where the device main body 2 is larger (such as a digital composite machine), it may be installed as figure 2 orientation shown. In addition, there are other arrangements, for example, the fixing unit 14 is configured from figure 2 The states shown are tilted left or right poses.

[0069] The fixing unit 14 has the pressure roller 44 , the fixing roller 45 , the heating roller 46 , and the heating belt 48 as...

no. 2 approach

[0138] Details of the fixing unit

[0139] Next, the fixing unit 14 of the second embodiment used in the image forming apparatus 1 will be described in detail.

[0140] Figure 11 It is a longitudinal sectional view showing the fixing unit 14 of the second embodiment. The fixing unit 14 of the second embodiment is the same as the first embodiment, and its basic components include a pressure roller 44 , a fixing roller 45 , a heating roller 46 , and a heating belt 48 . The description of these components 44 , 45 , 46 , 48 is therefore omitted.

[0141] The fixing unit 14 further includes an IH coil unit 150 outside the heating roller 46 and the heating belt 48 . The IH coil unit 150 includes an induction heating coil 52 , a pair of arc cores 54 , a pair of side cores 56 , and a center core 158 . The structures of the induction heating coil 52, the arch core 54, and the side core 56 of the IH coil unit 150 are substantially the same as those of the IH coil 50 in the first ...

no. 3 approach

[0188] Figure 17is a diagram showing the fixing unit 14 of the third embodiment. In the third embodiment, the notch 90 is formed in each block core 158 a instead of the shield member 160 , so that the cross section of each block core 158 a is arcuate.

[0189] Notch

[0190] A part of the block core 158a is cut away in the axial direction to form a notch 90 . The notch 90 can also be formed at the same time by using a molding die when the ferrite powder is sintered, or it can be formed by cutting it after it is made into a cylindrical shape (cylindrical shape) (finally, the cross section can be arc-shaped) .

[0191] In the third embodiment, too, an axial groove 158c and a circumferential groove 158d are formed inside the block core 158a, and protrusions 159a, 159b, and 159c are formed on the shaft member 159. However, since the notch 90 is formed, the axial groove 158c and the circumferential groove 158d are formed avoiding the notch 90 . The rotation or non-rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com