Secondary heat exchanger of condensing gas water heater

A gas-fired water heater and heat exchanger technology, applied in air heaters, fluid heaters, heat exchange equipment, etc., can solve the problems of imperfect design process, coating peeling off, complexity, etc., and achieve long-term product life guarantee, replacement The effect of improving thermal efficiency and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

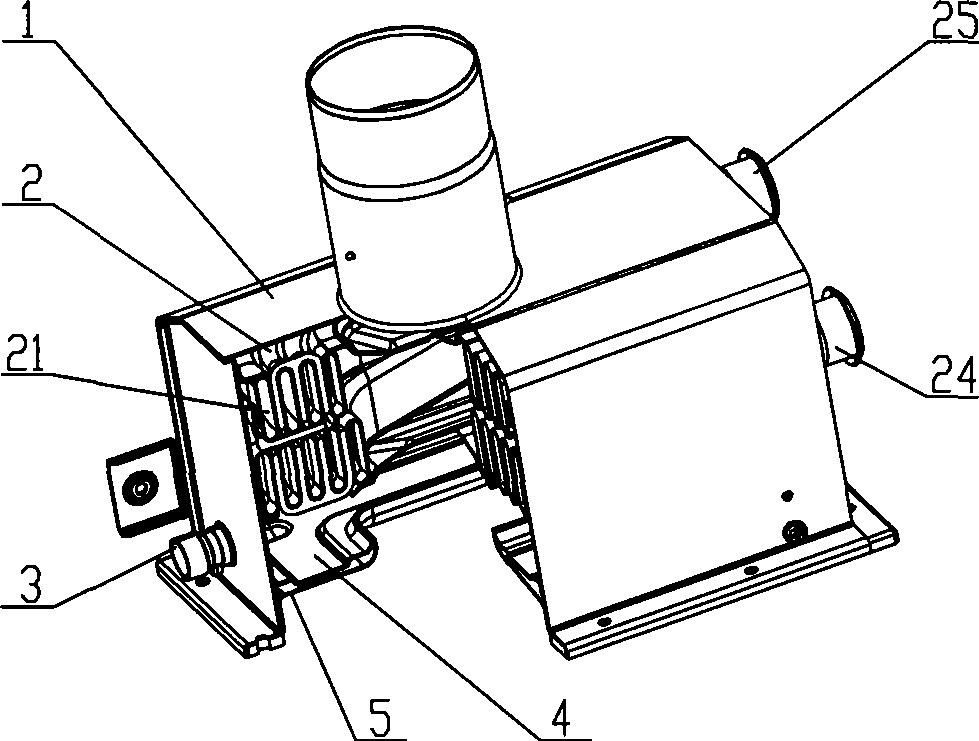

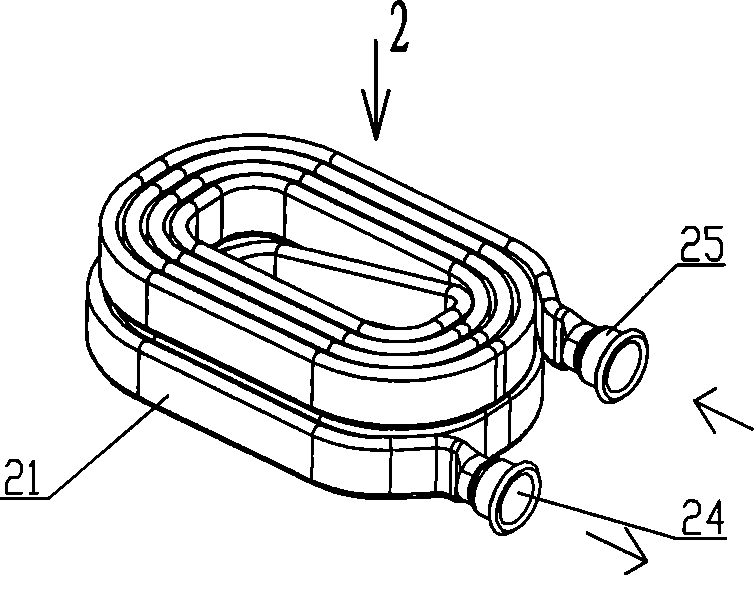

[0018] like Figure 1 to Figure 6 As shown, it includes: flue gas discharge assembly 1, secondary heat exchanger assembly 2 (water inlet joint 25 and water outlet joint 24), condensed water discharge pipe 3, condensed water collecting pan 4, heat shield 5 and so on.

[0019] The secondary heat exchanger of the condensing gas water heater of the present invention is used in the condensing gas water heater. The secondary heat exchanger assembly 2 is welded to the flue gas discharge assembly 1 . The secondary heat exchanger assembly 2 is provided with a double-layer coil heat exchanger 21, and the double-layer coil heat exchanger 21 is formed by spiraling the upper and lower layers of a single stainless steel seamless flat round tube; the double-layer coil The heat exchanger 21, the water inlet joint 25 and the water outlet joint 24 are welded on the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com