Composite micro-nano structure array on high light-transmission substrate and method and application thereof

A light-transmitting matrix and micro-nano structure technology, applied in the coupling of optical waveguides, optics, light guides, etc., can solve the problems of lack of comprehensive research and utilization of properties, and achieve easy large-scale preparation, increased fluorescence signal intensity, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

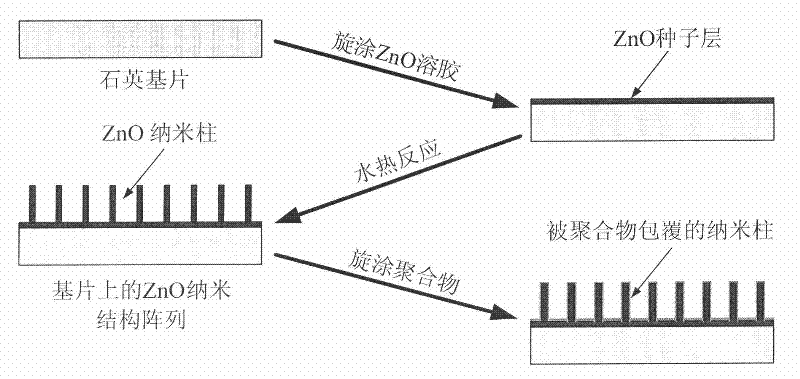

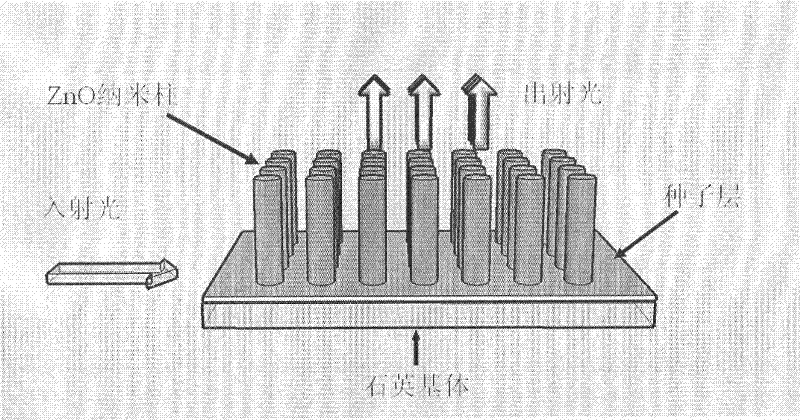

[0031] The preparation process of the ZnO nanocolumn array: 1. Pretreatment cleaning and hydrophilic treatment of the quartz substrate; 2. 3.29g Zn(Ac) 2 2H 2 O was dissolved in 30ml of ethylene glycol methyl ether, and 0.9ml of ethylenediamine was slowly added during stirring at 60°C, and a transparent colloid was obtained after 30 minutes; 3. Spin-coat the colloid on the pretreated Quartz substrate and post-baked at 400 ° C for 1 h; 4. Place the obtained substrate vertically in different concentrations of Zn(NO 3 ) 2 and (CH 2 ) 6 N 4 5. The substrate with zinc oxide nanocolumns obtained after hydrothermal growth was ultrasonically cleaned in high-purity water and ethanol, respectively, and then dried at 120°C for 1 hour. image 3 Shown is the same concentration of 0.01M Zn(NO 3 ) 2 and (CH 2 ) 6 N 4 The SEM image of the nano-column structure obtained by reacting in the mixed aqueous solution at 90°C for 6 hours shows that the distribution of the nano-columns is re...

Embodiment 2

[0033] Preparation process of zinc oxide mound structure array: Steps 1-3 are the same as in Example 1; 4. Prepare 0.02mol / L Zn(NO 3 ) 2 and 0.01mol / L (CH 2 ) 6 N 4 50ml of the mixed aqueous solution is formed, and 0.8ml of concentrated ammonia water with a concentration of 13mol / L is added; 5. The substrate prepared in 1-3 is vertically placed in the mixed solution, and reacted at 90°C for several hours; 6. Same as in Example 1 In step 5, an array of mound structures is obtained.

Embodiment 3

[0035] Preparation process of porous alumina array: 1. Dissolve 15g oxalic acid in 300ml ultrapure water to obtain oxalic acid solution, dissolve 10ml phosphoric acid in 220ml ultrapure water to obtain phosphoric acid pore-enlarging solution, dissolve 7.6ml phosphoric acid and 3.6g chromium trioxide Prepare a mixture of phosphoric acid and chromic acid in 400ml of ultra-pure water; 2. Immerse the polished high-purity aluminum sheet in the oxalic acid solution, and perform electrochemical corrosion for 1 hour in a water bath at 4°C, with a voltage of 50V and a current of 0.02~ 0.34A; 3. Immerse the corroded aluminum sheet in a mixture of chromic acid and phosphoric acid, and corrode it for 50 minutes at 50°C; 4. Then put the corroded aluminum sheet in an oxalic acid solution for 1 hour of electrochemical corrosion in a water bath at 4°C. The voltage is 50V, and the current is 0.02-0.20A; 5. The obtained substrate is immersed in a phosphoric acid pore-enlarging solution, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com