Automatic feeding device for four-column hydraulic column system

An automatic feeding and hydraulic technology, which is applied in the application of ultra-high pressure process, the method of chemically changing substances by using atmospheric pressure, chemical instruments and methods, etc., can solve the problem of false signal sending, hand pressing accidents, and lack of concentration And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

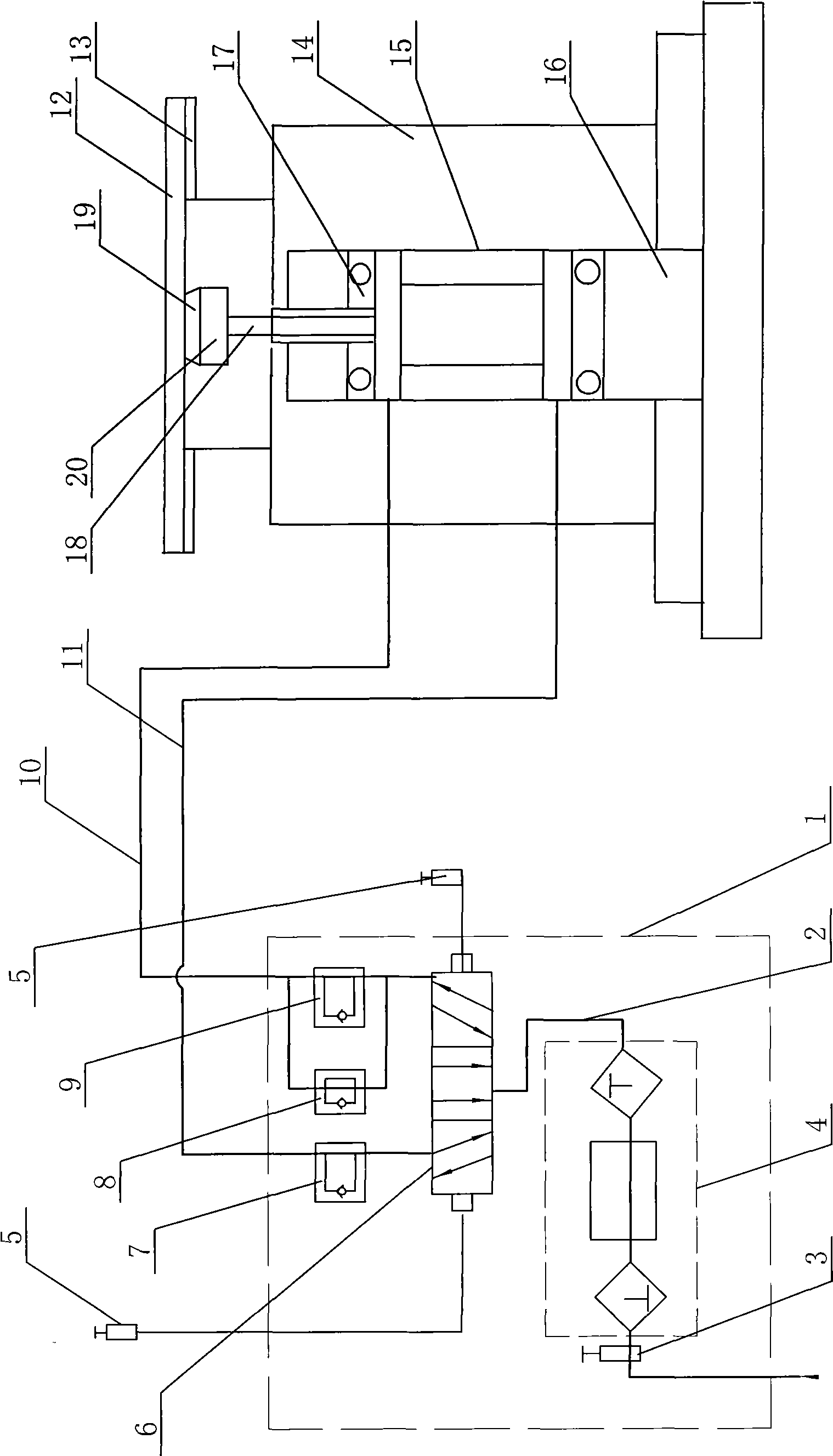

[0014] Such as figure 1 As shown, the automatic feeding device of the four-column hydraulic pressure column system of the present invention includes a power drive part, an electrical control part and a mechanical execution part. The mechanical execution part includes a bracket 16, on which a cylinder 15 is vertically arranged, and the piston 17 of the cylinder 15 is fixedly connected with a push rod 18, and the top of the push rod 18 is horizontally provided with a loading and unloading dial 12, and the lower part of the loading and unloading dial 12 is provided with a The bevel gear 19 is provided with a material receiving device 13 below the edge of the loading and unloading dial 12, and the ejector rod 18 and the bevel gear 19 are connected through a one-way transmission mechanism 20. The one-way transmission mechanism 20 is provided with parts and worms similar to the principle of a bicycle flywheel , when the ejector rod 18 moves upwards, the linear motion of the worm is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com