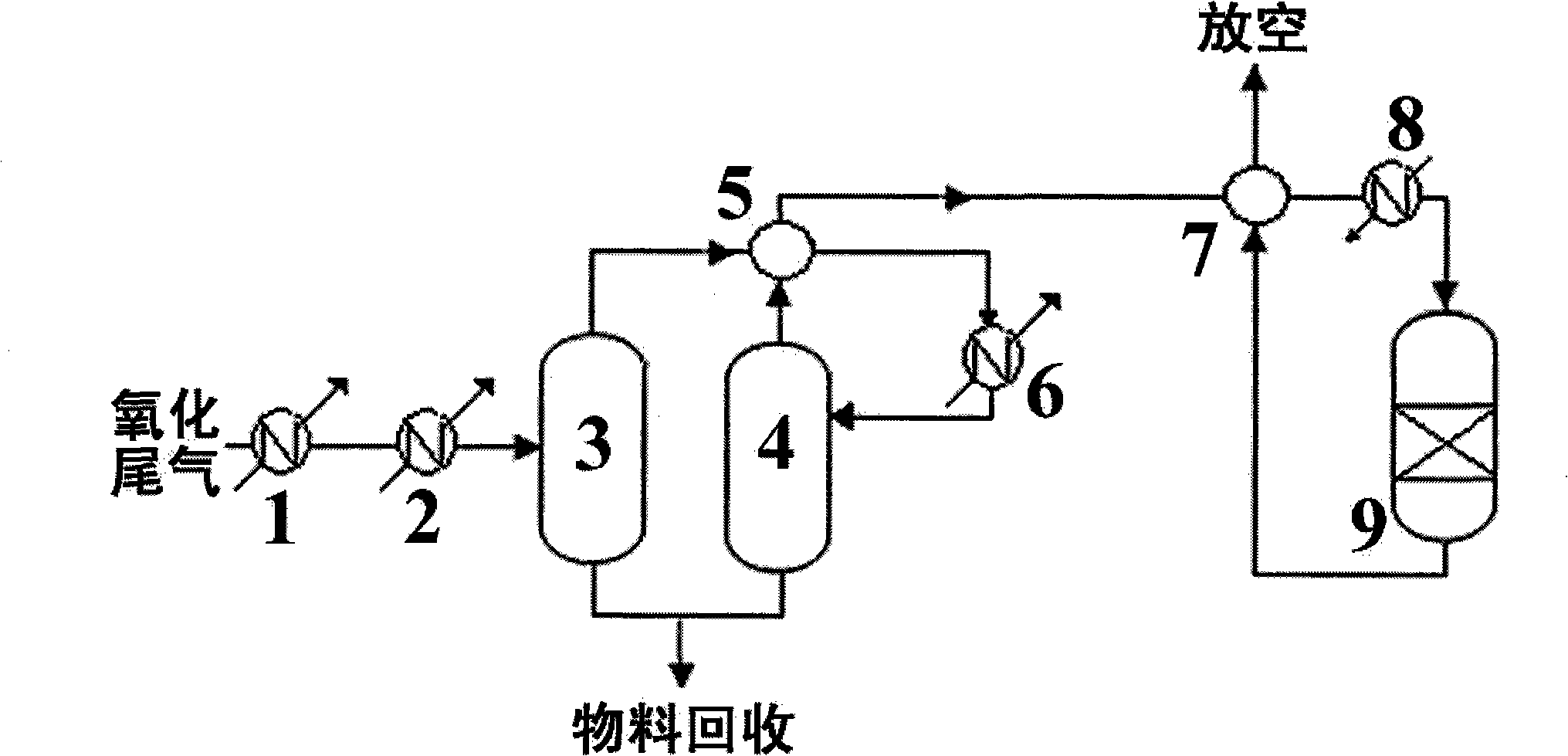

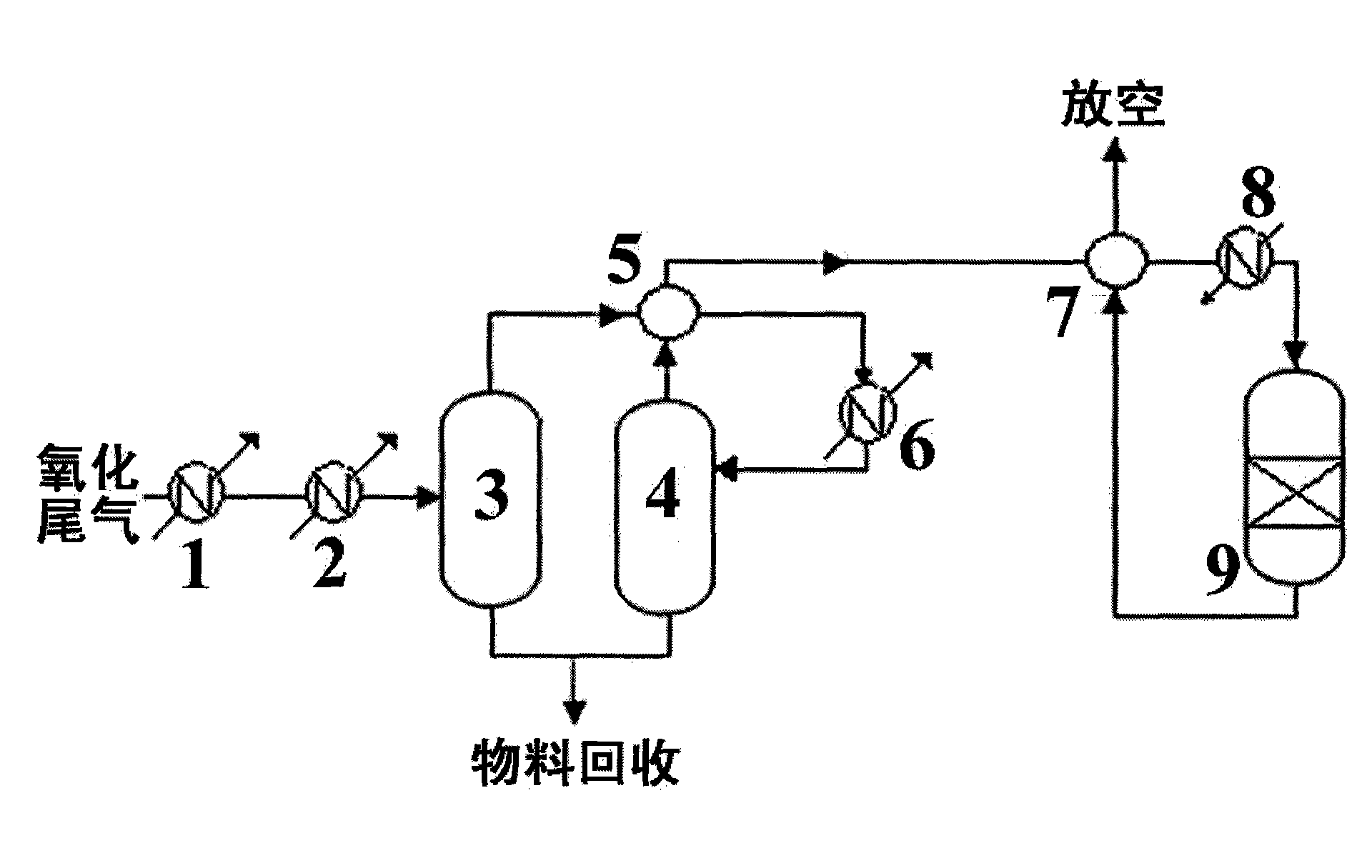

Process for treating oxidized exhaust gas

A technology for oxidizing tail gas and process, applied in the chemical industry, incinerator, steam condensation and other directions, can solve the problems of increased energy consumption, high one-time investment, increased energy consumption, etc., to achieve low operating costs, simple process, lower temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The tail gas of phenol and acetone produced by a certain enterprise contains 10000mg / m of cumene 3 (in addition to entrained liquid phase), cumene hydroperoxide 0.01wt%, benzene 300mg / Nm 3 , Toluene 30mg / Nm 3 , Non-methane total hydrocarbons 45×10 4 mg / Nm 3 , the tail gas temperature is 80~100℃, the flow rate is 19000Nm 3 / h After heat exchange by the heat recovery heat exchanger (1), the temperature is 60-70°C, and after being cooled by cooling water in the cooler (2), the temperature is 25-40°C, and then enters the first gas-liquid separation tank for gas-liquid Separation, the uncondensed gas discharged from the top, after being cooled by the heat exchanger (5), the temperature is 15-25°C, and further cooled by the cryocooler (6), the temperature is 1.4°C, after that, it enters the second gas-liquid separation The tank (4) performs gas-liquid separation, and the uncondensed gas discharged from the top of the second gas-liquid separation tank first passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com