Preparing method for mildew inhibitor for feed

A compound, antifungal technology, applied in the preservation method of animal feed raw materials, animal feed, animal feed, etc., can solve the problem of irritation, palatability, safety, and bacteriostatic properties, and chemical antifungal agents are irritating. , allergy hazards and other problems, to achieve good anti-mildew effect, improved anti-mildew effect, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

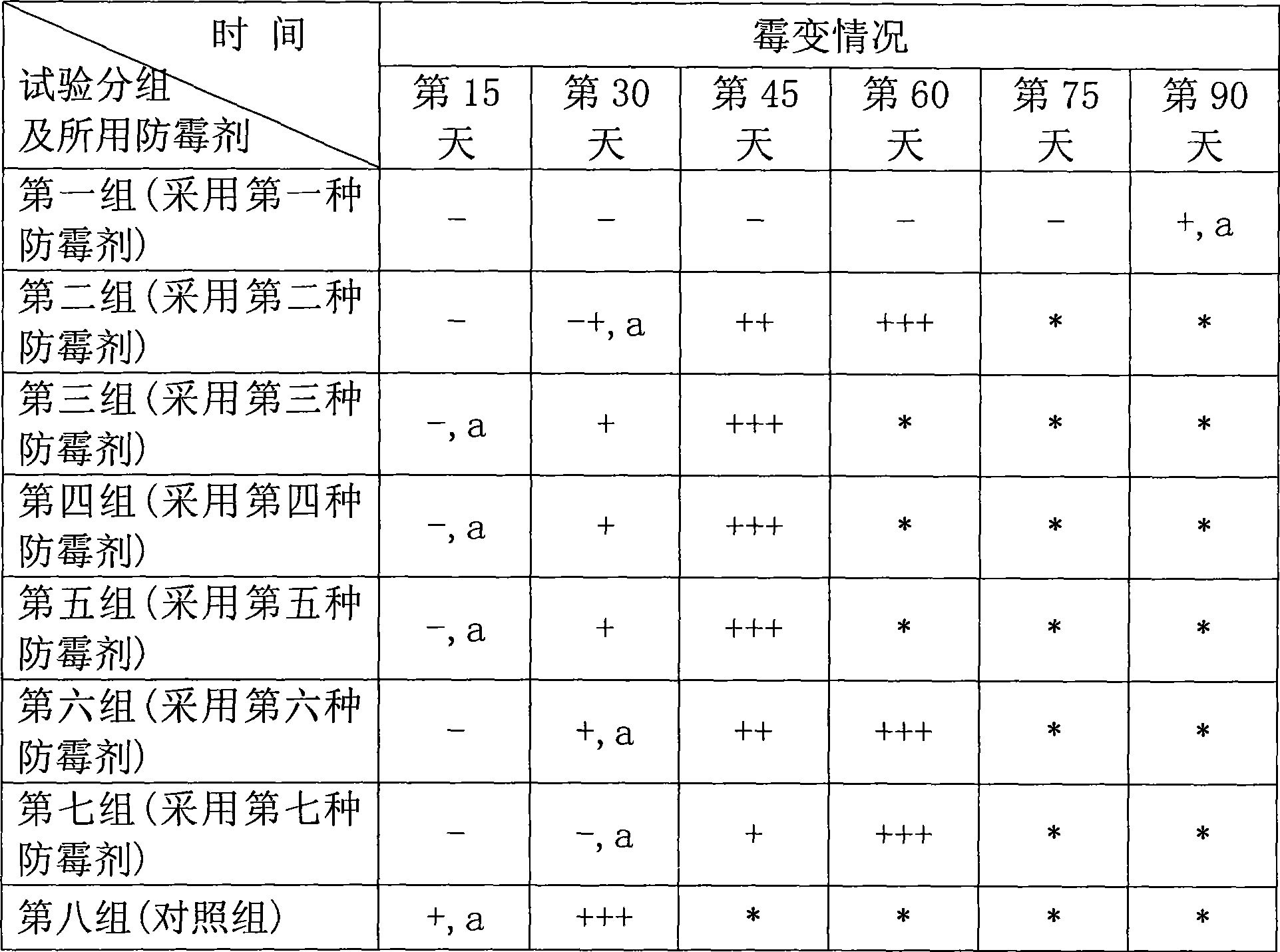

Image

Examples

Embodiment 1

[0029] 1) Add 25 parts of clove oil, 20 parts of cinnamon oil and 5 parts of acetic acid into the reaction kettle, start stirring and adjust to 40r / min, heat up to 50°C within 30 minutes, and then add 5 parts of natamycin , keep warm until completely dissolved to obtain the mixed material A;

[0030] 2) Put 45 parts of corn cob powder into the mixer, start stirring and adjust to 30r / min, add the mixture material A obtained in the above step 1) into the mixer for suction and mixing under stirring, and open the cooling water in the interlayer of the mixer at the same time After cooling, after all the mixed material A is put into the mixer, continue mixing for 15 minutes, after cooling, the mixture is discharged from the mixer, and through pulverization, screening, inspection and packaging, the composite feed antifungal agent of the present invention is obtained.

Embodiment 2

[0032] 1) Add 10 parts of clove oil, 20 parts of cinnamon oil and 5 parts of propionic acid into the reaction kettle, start stirring and adjust to 80r / min, heat up to 60°C within 15 minutes, and then add 15 parts of natamycin Wherein, insulation is until fully dissolved, and mixed material A is obtained;

[0033] 2) Put 20 parts of silica powder and 40 parts of fine rice bran into the mixer, turn on the stirring and adjust it to 40r / min, and add the mixed material A obtained in the above step 1) into the mixer for suction and mixing while stirring. The cooling water in the interlayer of the mixer is cooled. After all the mixed material A is put into the mixer, continue to mix for 15 minutes. After cooling, the mixture is discharged from the mixer. Feed antifungal agent.

Embodiment 3

[0035] 1) Add 25 parts of clove oil, 10 parts of cinnamon oil, 5 parts of acetic acid and 10 parts of propionic acid into the reaction kettle, start stirring and adjust to 60r / min, heat up to 55°C within 20min, and then add 8 parts of sodium Tamycin was added therein and kept warm until completely dissolved to obtain mixed material A;

[0036] 2) Put 25 parts of expanded perlite and 10 parts of silica powder into the mixer, then add the mixed material A obtained in the above step 1) into the mixer for suction and mixing, and discharge the mixture out of the mixer after cooling, crushing, sieving Separation, inspection, packaging, promptly obtain the composite feed antifungal agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com