Atomizing heater

A spray heating and spray nozzle technology, applied in the field of bathroom equipment, can solve the problems of insufficient heat exchange between aerosol and air, coarse aerosol particles, and low utilization rate of hot water, so as to achieve good hot water atomization effect and aerosol particles The effect of fineness and high utilization rate of hot water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

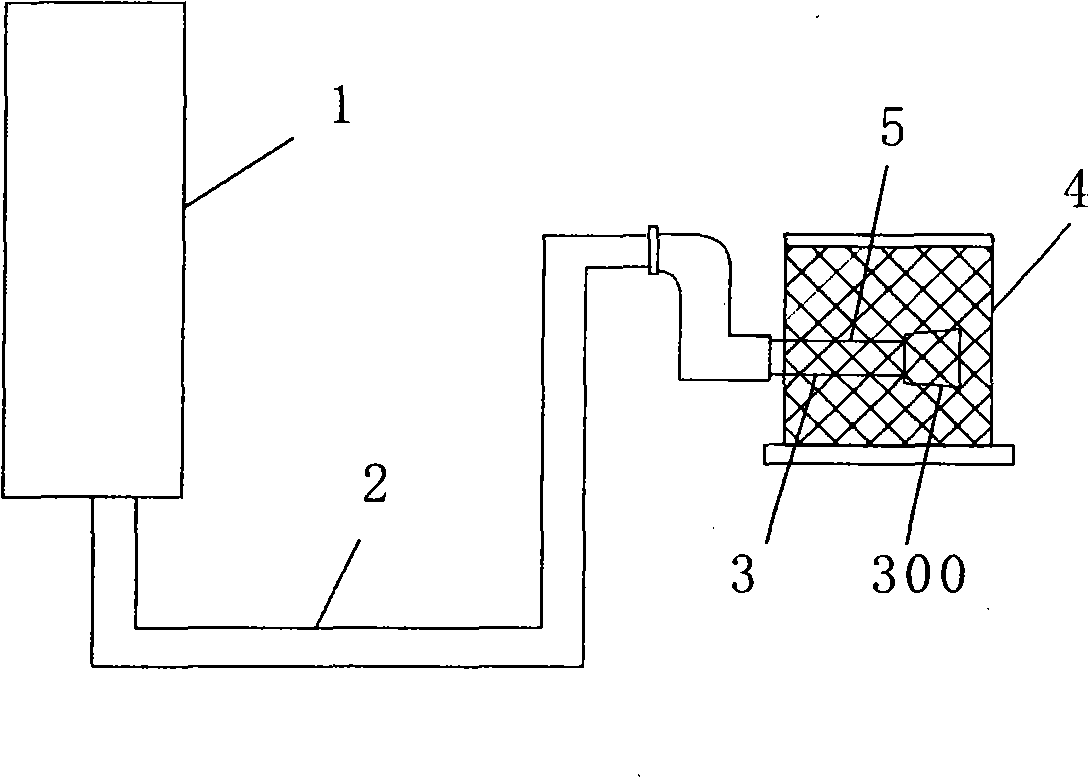

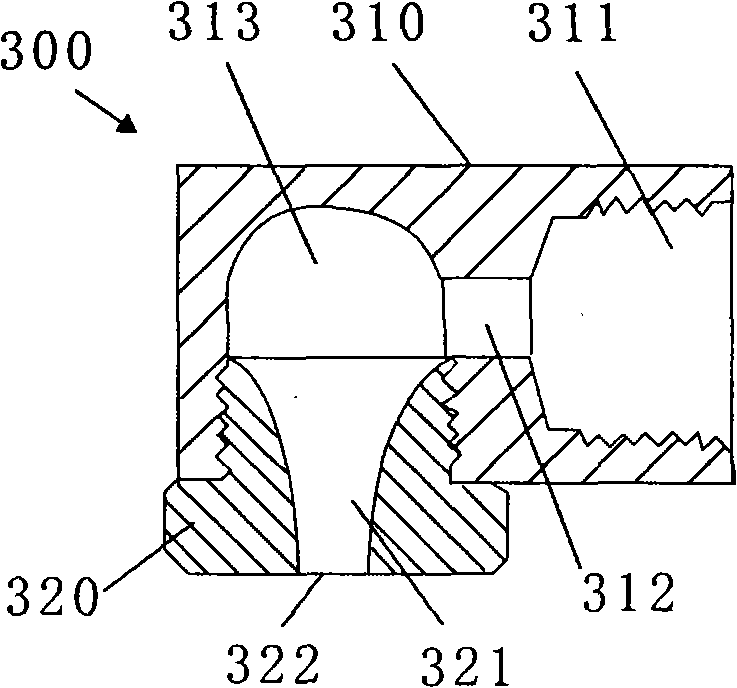

[0028] Such as figure 1 As shown, the spray heater of the present embodiment includes a water heater 1 , a curved water pipe 2 , a spray generator 3 , and a net cover 4 .

[0029] Wherein, the hot water outlet of the water heater 3 is connected to the water inlet of the spray generator 3 through the curved water pipe 2 , and the mesh cover 4 is covered around the spray generator 3 . In this spray heater, the function of the spray generator 3 is to generate water mist, and the function of the net cover 4 is to make the water mist generated by the spray generator 3 collide with the net cover 4, so that the hot water mist can be made finer, And it can also prolong the residence time of the hot water mist in the air, and the heat exchange with the air is more sufficient. In addition, on the one hand, it also prevents the hot water from directly acting on the human body, so as to avoid people being scalded when bathing. In this embodiment, the spray generator 3 is composed of an u...

Embodiment 2

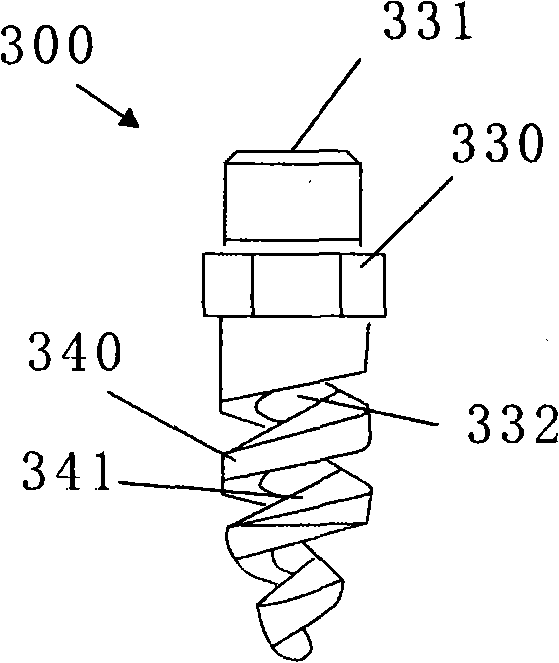

[0034] The overall structure of the spray heater of the present invention is the same as that of the spray heater of Embodiment 1, the difference is the structure of the ultra-fine atomizing nozzle 300 .

[0035] Such as image 3As shown, the ultra-fine atomizing nozzle 300 of this embodiment has a spray head 330 and a spray guide 340 . One end of the shower head is a water inlet 331, which can communicate with the water inlet pipe 5, and the other end is a spout 332, and the diameter of the spout 332 is smaller than that of the water inlet 331 of the shower head 330. The injection guide 340 is integrated with the spray head 330 , and extends downwards in a conical spiral form from the nozzle 332 of the spray head 330 . The number of helical turns of the spray guide 340 is two turns or three turns. In this embodiment, a spray guide with three helical turns is used, and the spray guide 340 has a liquid shock that is inclined relative to the central axis of the spiral. Face 34...

Embodiment 3

[0038] The overall structure of the mist heater in this embodiment is also the same as that in Embodiment 1, except for the structure of the ultra-fine atomizing nozzle 300 .

[0039] Such as Figure 4 As shown, the ultra-fine atomizing nozzle 300 of this embodiment also has a spray head 330 with the same structure as in Embodiment 2, the difference is that there is a planar liquid impingement plate 350 below the nozzle 332 of the spray head 330 . The planar liquid impingement plate 350 is connected and fixed below the nozzle 332 of the nozzle 330 through a steel wire connector 351 . In this embodiment, the planar liquid impingement plate 350 is disc-shaped, with an area five times that of the nozzle, and is parallel to the nozzle 332 of the nozzle 330 . Of course, in the actual manufacturing process, the planar liquid impingement plate 350 can adopt other shapes as required, and can also form a certain angle with the plane of the nozzle 332 of the nozzle 330 .

[0040] With...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com