Electric control integrated system of carburetor

An integrated system and carburetor technology, applied in the direction of electrical control, charging system, engine control, etc., can solve the problem that the work efficiency needs to be improved, the motorcycle can not meet the emission standard above Euro 3, and the working noise of the air supplement solenoid valve can be reduced And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

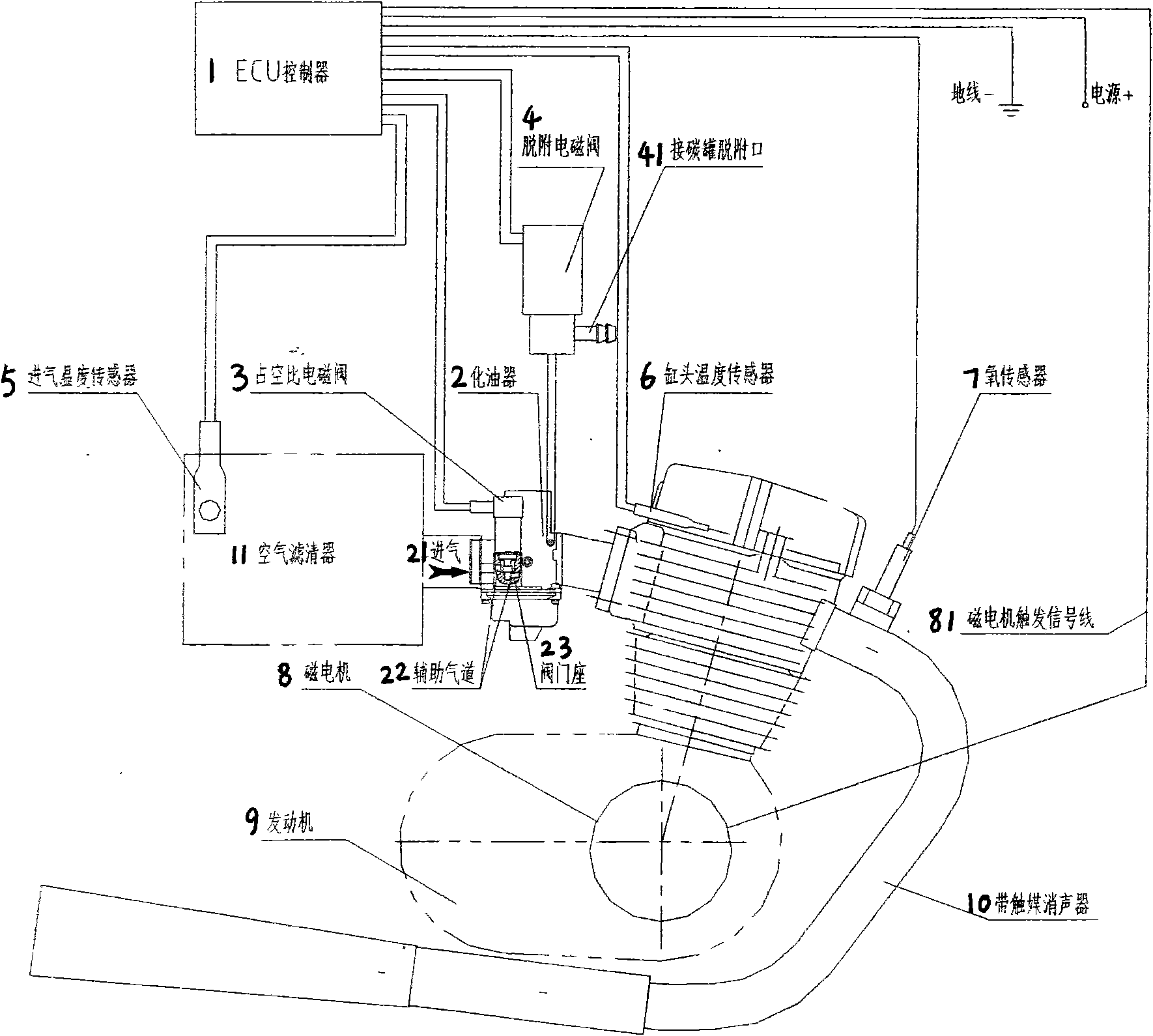

[0032] see figure 1 -As shown in the schematic diagram of the carburetor electronically controlled integrated system of the present invention, 1 electronic controller (ECU) respectively communicates with the duty ratio solenoid valve 3, the desorption solenoid valve 4, the intake air temperature sensor 5, and the cylinder head temperature sensor through the signal line 6. The oxygen sensor 7 is connected; the magneto trigger signal line 81 is connected to the magneto 8 . The duty cycle solenoid valve 3 is installed and fixed on the valve seat 23 of the carburetor 2 . The probe of the intake air temperature sensor 5 is installed on the air intake of the air cleaner 11 . The probe of cylinder head temperature sensor 6 is installed on the cylinder head position of engine 9 . The probe of oxygen sensor 7 is installed on the exhaust port of engine 9 .

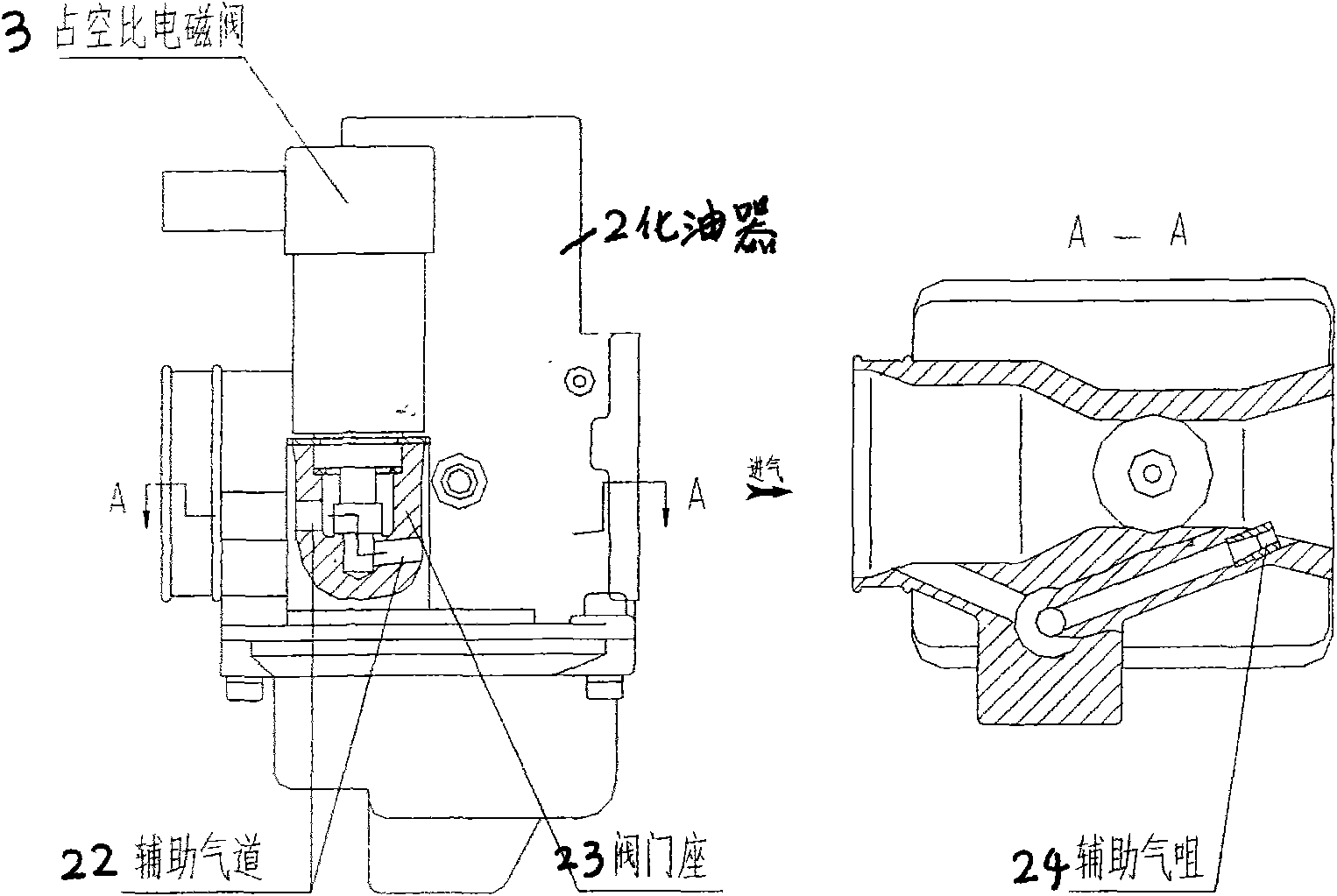

[0033] see Figure 2 present As shown in the schematic diagram of the integration of the new carburetor and the duty ratio so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com