Construction method for building large-scale offshore wind farm with depth more than 2m

A construction method and technology for wind farms, applied in water conservancy projects, buildings, artificial islands, etc., can solve the problems of shallow seawater depth, large changes, inability to meet construction requirements, etc., and achieve the effects of low construction cost, simple construction, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

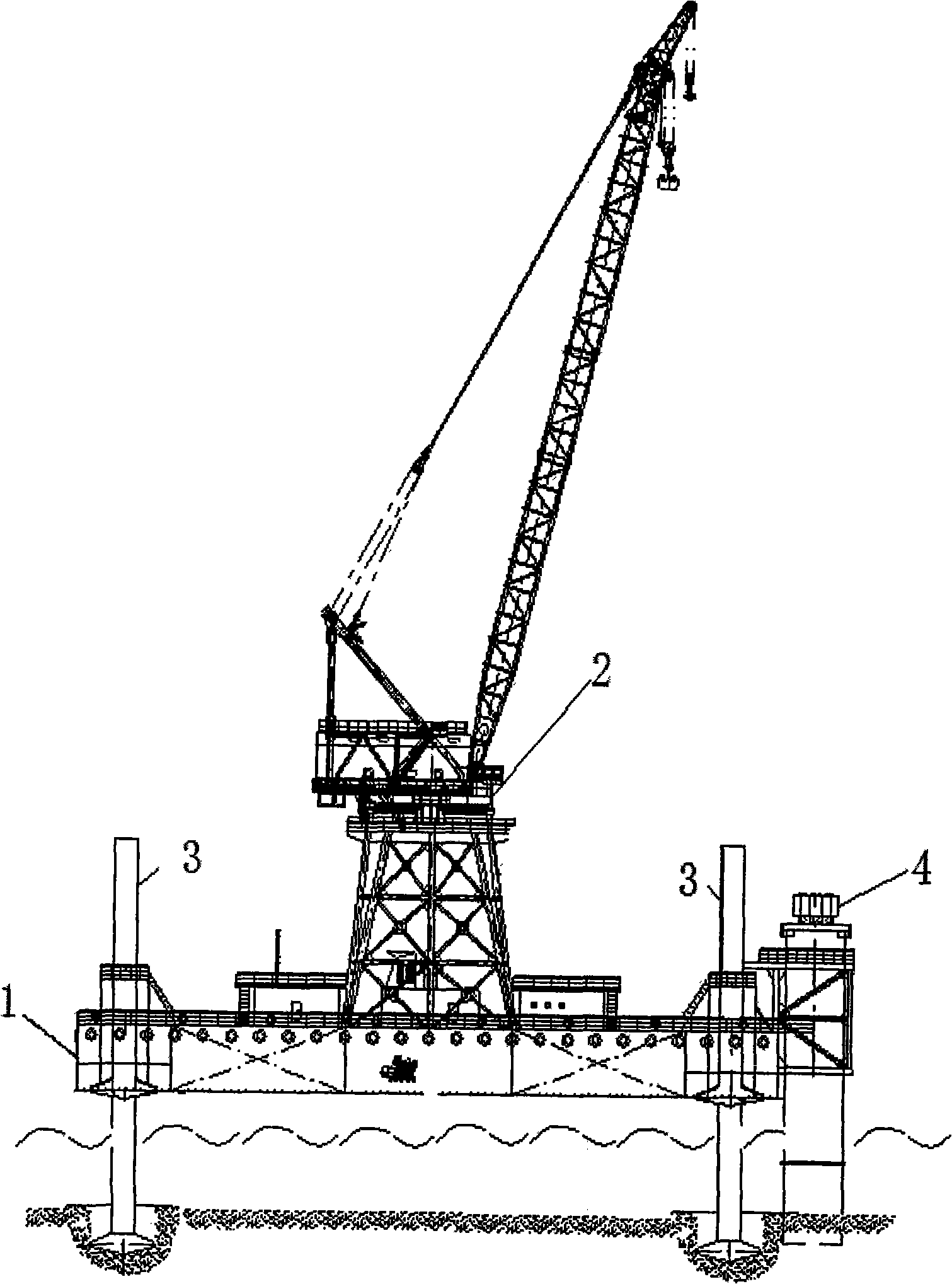

[0025] Referring to the accompanying drawings, the construction method of the present invention for large-scale offshore wind farm construction in areas where the water depth is greater than 2 meters mainly includes the following steps:

[0026] A) Use the shallow water tugboat to tow the construction ship to the set position. After the construction ship is positioned, the shallow water tugboat can leave;

[0027] B) start the hoisting device 3 on the construction ship, so that the hull 1 rises to 2-3 meters above the water surface, and now the construction ship obtains a solid foundation, and the hull is not affected by currents and waves;

[0028] C) The shallow water tugboat tows the transport barge equipped with steel pipe piles, wind turbine operating platform, tower, wind turbine cabin, hub, blades and other equipment to the vicinity of the construction ship and anchors for positioning;

[0029] D) The main hoist of the 400-ton full-slewing crane 2 on the construction sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com