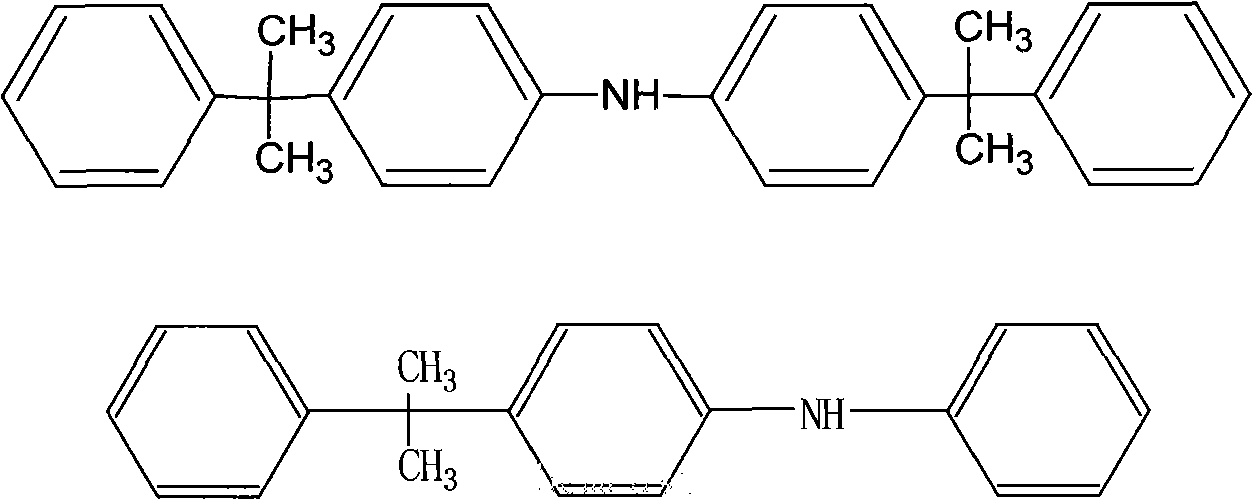

Method for preparing mixture of 4-(alpha, alpha-dimethylbenzyl) diphenylamine and 4,4-bis (alpha, alpha-dimethylbenzyl) diphenylamine

A technology of dimethylbenzyl and diphenylamine, which is applied in the field of preparation of alkylated diphenylamine, can solve problems such as equipment corrosion and high labor intensity, and achieve the effects of no three wastes, reduced costs, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In a 1L reactor equipped with a stirrer, reflux condenser, feeding device and nitrogen protection device, add 16.9g of diphenylamine (99.8% purity) and 2g of activated clay, heat to 60-80°C, and wait until the diphenylamine is completely melted , start stirring and heat up to 120-135°C. Prepare 26g of α-methylstyrene at the same time, and slowly add it to the reactor through the feeding device. After all the α-methylstyrene is added, the reaction mixture is kept for about 4 hours, and the temperature is controlled at 125-145°C, and then Cool down to below 120°C and perform hot filtration. After filtering out the catalyst, the filtrate was poured into a four-necked flask equipped with a thermometer, a bubbling device and a condenser tube, distilled under negative pressure (2.66k Pa), steamed to 245-250°C to stop distillation, cooled, and collected the still liquid to obtain 36.5g Product, yield 85.1%.

Embodiment 2

[0025] In a 1L reactor equipped with a stirrer, a reflux condenser, a feeding device and a nitrogen protection device, add 169g of diphenylamine (purity 99.8%) and 25g of activated clay for heating (heating and dehydration for two hours before use), and heat to 60~ 80°C, after the diphenylamine is completely melted, start stirring and raise the temperature to 120-135°C. At the same time, prepare 253g of α-methylstyrene and slowly add it to the reactor through the feeding device. After all the α-methylstyrene is added, the reaction mixture is kept for about 4-6 hours, and the temperature is controlled at 125-155°C. , and then lower the temperature to below 120°C for hot filtration. After filtering out the catalyst, pour the filtrate into a four-neck flask equipped with a thermometer, a bubbling device and a condenser tube, distill under negative pressure (13.30k Pa), steam to 200-245°C to stop distillation, cool, and collect the still liquid to obtain 358g of product , The yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com