Structure of spiral-flow aeration sedimentation sewage treatment tank and using method thereof

A sewage treatment tank and aeration technology, applied in the direction of aerobic and anaerobic process treatment, etc., can solve the problems of the treatment system not working normally, increase the hydraulic load of the sedimentation tank, increase the total sludge volume of the sedimentation tank, etc., and achieve the reduction of sewage The circulation and operation link, increasing the depth of the pool, and improving the effect of aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Aiming at the deficiencies of the conventional floating growth method bioreactor, the present invention provides a kind of floating growth method bioreactor which can make the activated sludge reflux in the reactor, which can improve the microbial concentration and sewage treatment capacity in the bioreactor, and reduce the The return flow operation of the sludge in the sedimentation tank simplifies the operation and saves energy. The micro-flow operation in the later stage of the cyclone sedimentation treatment is beneficial to the sedimentation of the activated sludge and improves the effluent water quality of the sewage treatment tank.

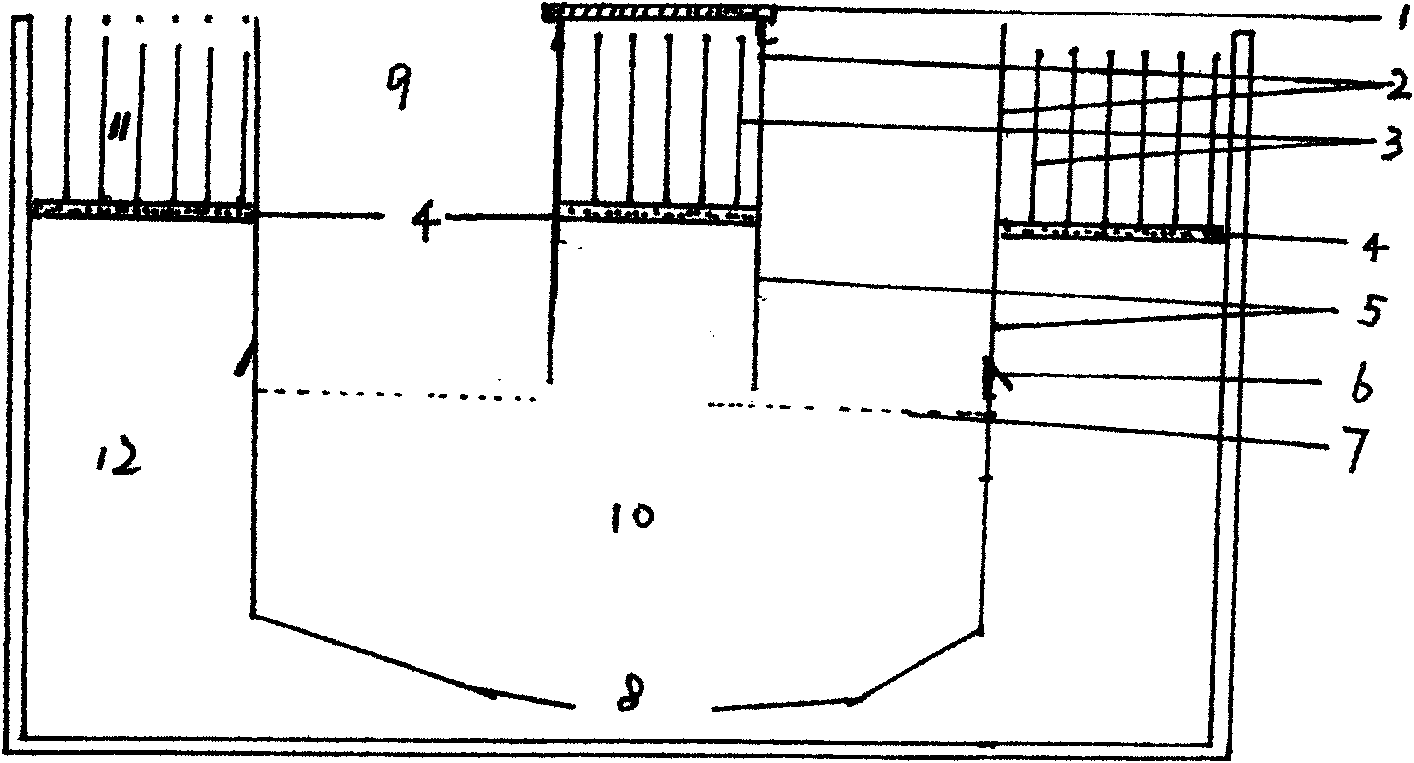

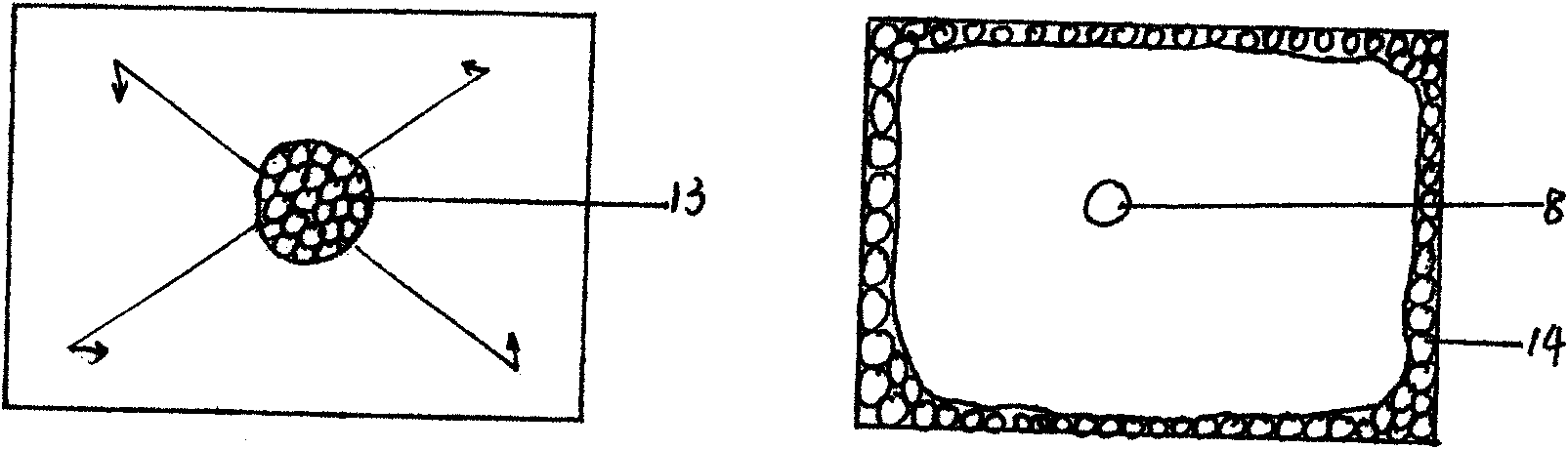

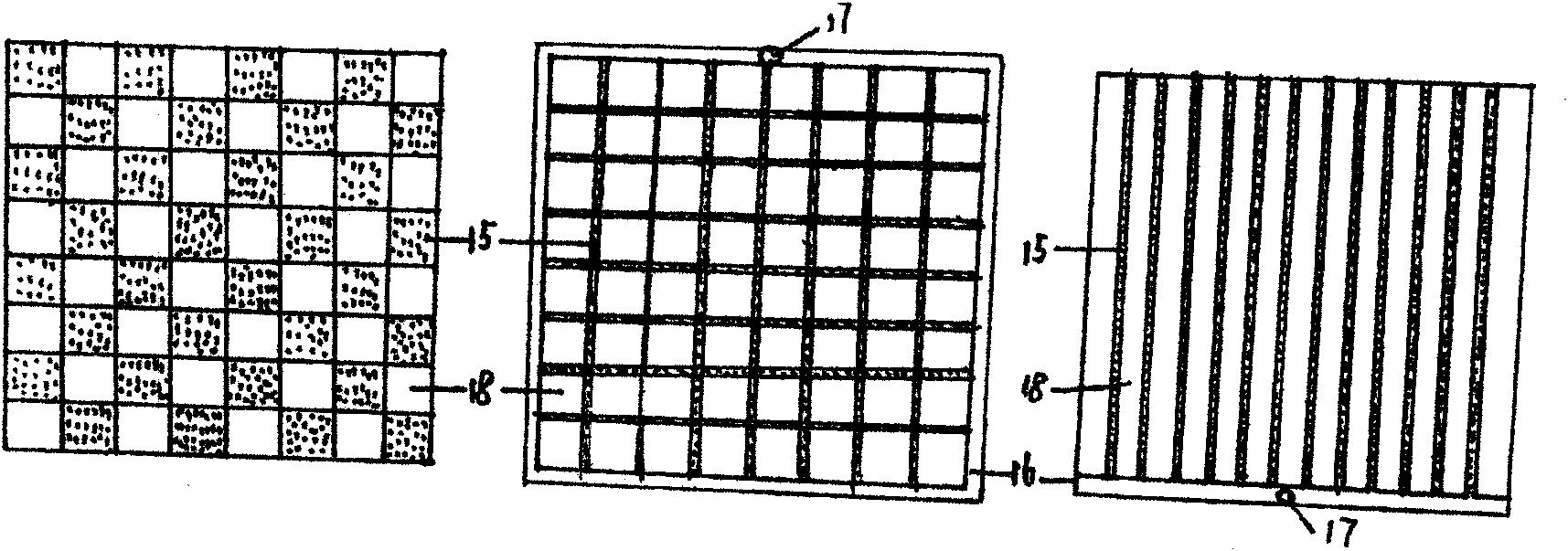

[0032] The structure and use method of the cyclone aeration sedimentation sewage treatment tank: the main process of air flotation separation and biological treatment is organically combined in one container, and fixed water pumping and aeration devices 14 are installed at the four corners or around the container to selectively The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com