Preparation method of titanium dioxide europium-doped nano-film sol

A technology of titanium dioxide and nanosheets, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of complex process and high cost of raw materials, and achieve the effects of good optical performance, energy saving and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

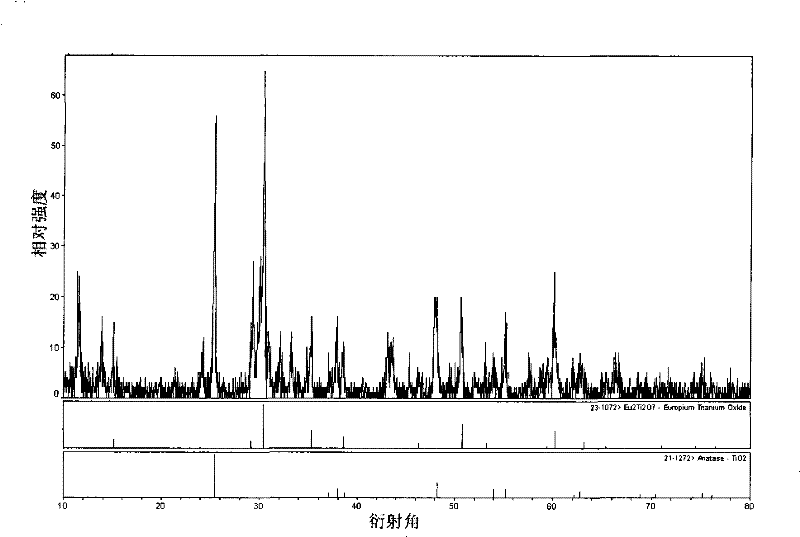

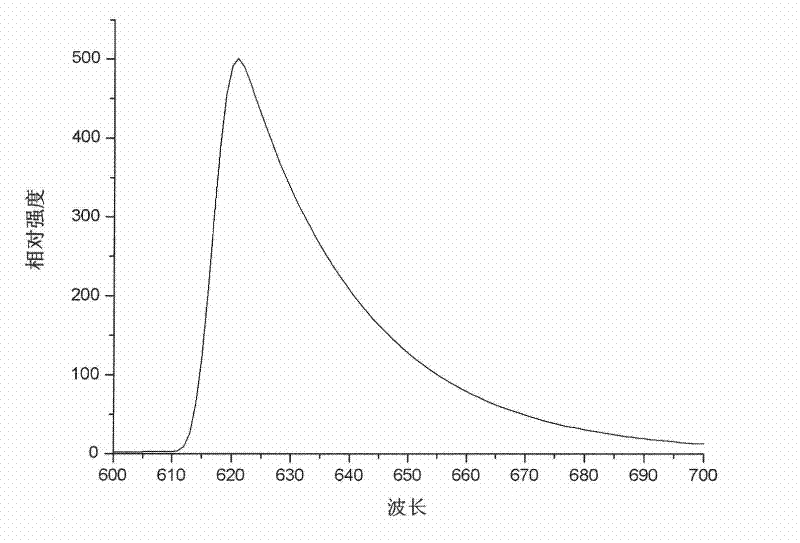

Image

Examples

Embodiment 1

[0020] a, 5g metatitanic acid (H 2 TiO 3 ) was washed with distilled water several times, put in an oven and baked at 60°C for 12 hours, and 0.01g of europium trioxide (Eu 2 o 3 ) is dissolved in 0.16ml of 1mol / l nitric acid to obtain europium ions.

[0021] b. Add 5g H 2 TiO 3 with 6.9g K 2 CO 3 Mix evenly, take 0.16ml of europium ions prepared in a and add to the mixture. At this time, the mass fraction of europium accounts for 0.2% of the mass fraction of titanium, then add 5ml of absolute ethanol, and grind thoroughly.

[0022] c. Put the mixture in b in a muffle furnace and react at 600°C to 1000°C for 6 hours.

[0023] d. Take out the calcined material, add 1mol / L hydrochloric acid to stir at a ratio of 4g / L, filter and wash after 24 hours, and add tetra-n-butylammonium hydroxide to the filter cake at a ratio of 0.4g / L to stir for 24 hours, and then / min high-speed centrifuge for 10 minutes, the upper liquid is titanium dioxide doped europium nanosheet transparen...

Embodiment 2

[0025] a. Wash 10g of metatitanic acid several times with distilled water, put it in an oven and dry it at 60°C for 12 hours, take 0.1g of europium trioxide (Eu 2 o 3 ) was dissolved in 1.6ml of 1mol / l nitric acid to obtain europium ions.

[0026] b. Mix 10g H 2 TiO 3 with 13.8K 2 CO 3 Mix evenly, add 1.6ml of europium ions prepared in a to the mixture, at this time, the mass fraction of europium in titanium is 1%, add 5ml of absolute ethanol, and grind thoroughly.

[0027] c. Put the mixture in b in a muffle furnace and react at 800°C for 8 hours.

[0028] d. Take out the calcined material, add 1mol / L hydrochloric acid at a ratio of 4g / L and stir, filter and wash after 36 hours, add ethylenediamine to the filter cake at a ratio of 0.4g / L and stir for 36 hours, and then stir at 10000r / min Centrifuge in a high-speed centrifuge to obtain the supernatant which is the corresponding titanium dioxide-doped europium nanosheet transparent sol.

Embodiment 3

[0030] a, the 10 metatitanic acid (H 2 TiO 3 ) was washed with distilled water several times, put in an oven and baked at 60°C for 12 hours, and 0.3g of europium trioxide (Eu 2 o 3 ) was dissolved in 4.8ml of 1mol / l nitric acid to obtain europium ions.

[0031] b. Mix 10g H 2 TiO 3 with 13.8gK 2 CO 3 Mix evenly, add 4.8ml of europium ion prepared in a to the mixture, at this time, europium accounts for 3% of the mass fraction of titanium, add 5ml of absolute ethanol, and grind thoroughly.

[0032] c. Put the mixture in b in a muffle furnace and react at 800°C for 12 hours.

[0033] d. Take out the calcined material, add 1mol / L hydrochloric acid at a ratio of 4g / L and stir, filter and wash after 72 hours, add tetra-n-butylammonium hydroxide and stir at a ratio of 0.4g / L for the filter cake for 72 hours, and then / min high-speed centrifuge to obtain the corresponding transparent sol of titanium dioxide doped europium nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com