Preparation of side-pocket mushroom cultispecies by adopting plastic breather bags

A technology of plastic bags and cultivars, applied in the field of microbial technology and its equipment, can solve the problems of inconvenient transportation, slow growth, backward production technology, etc., and achieve the effects of shortening the cultivation time, convenient and quick operation, and shortening the growth distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

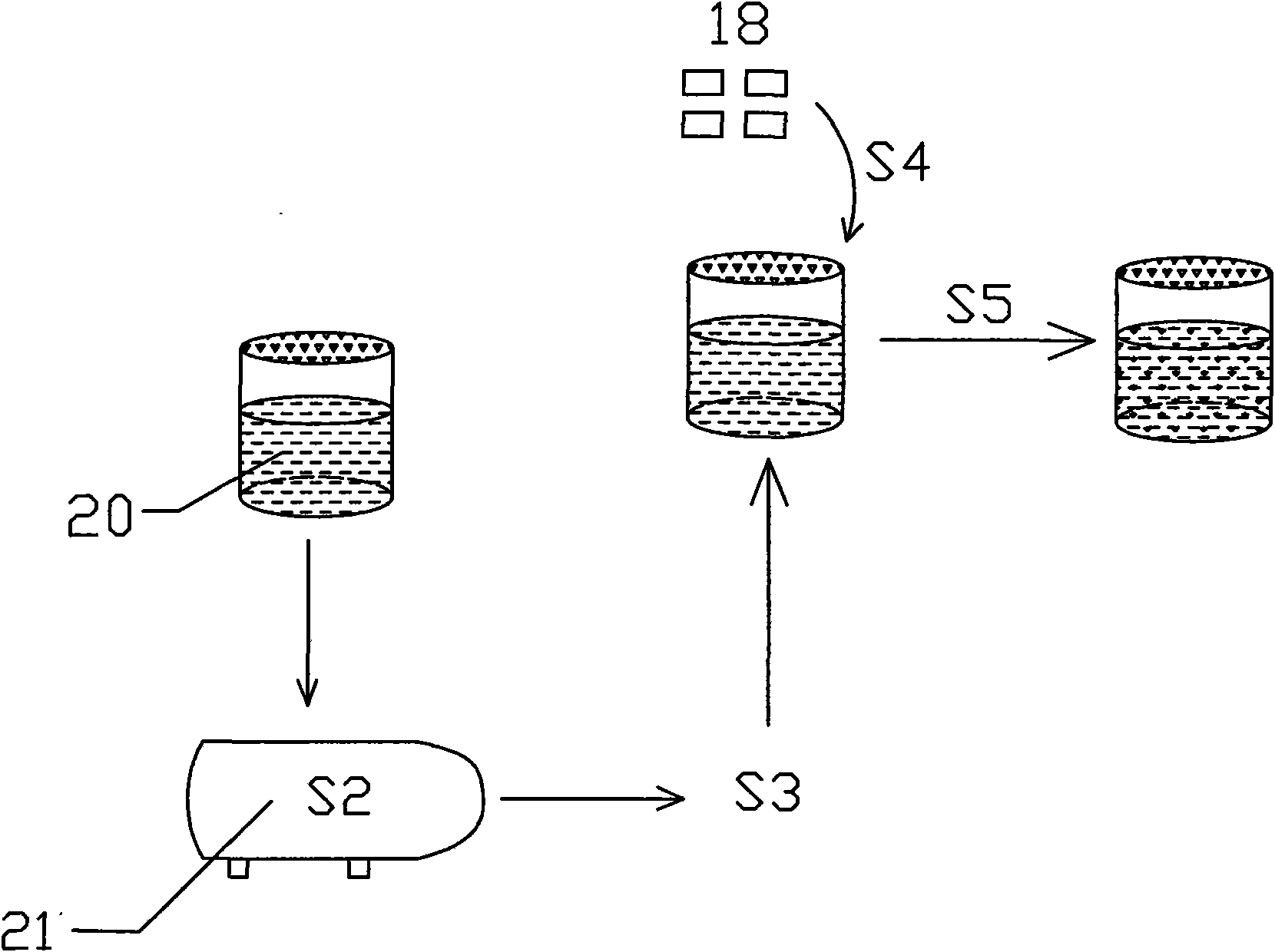

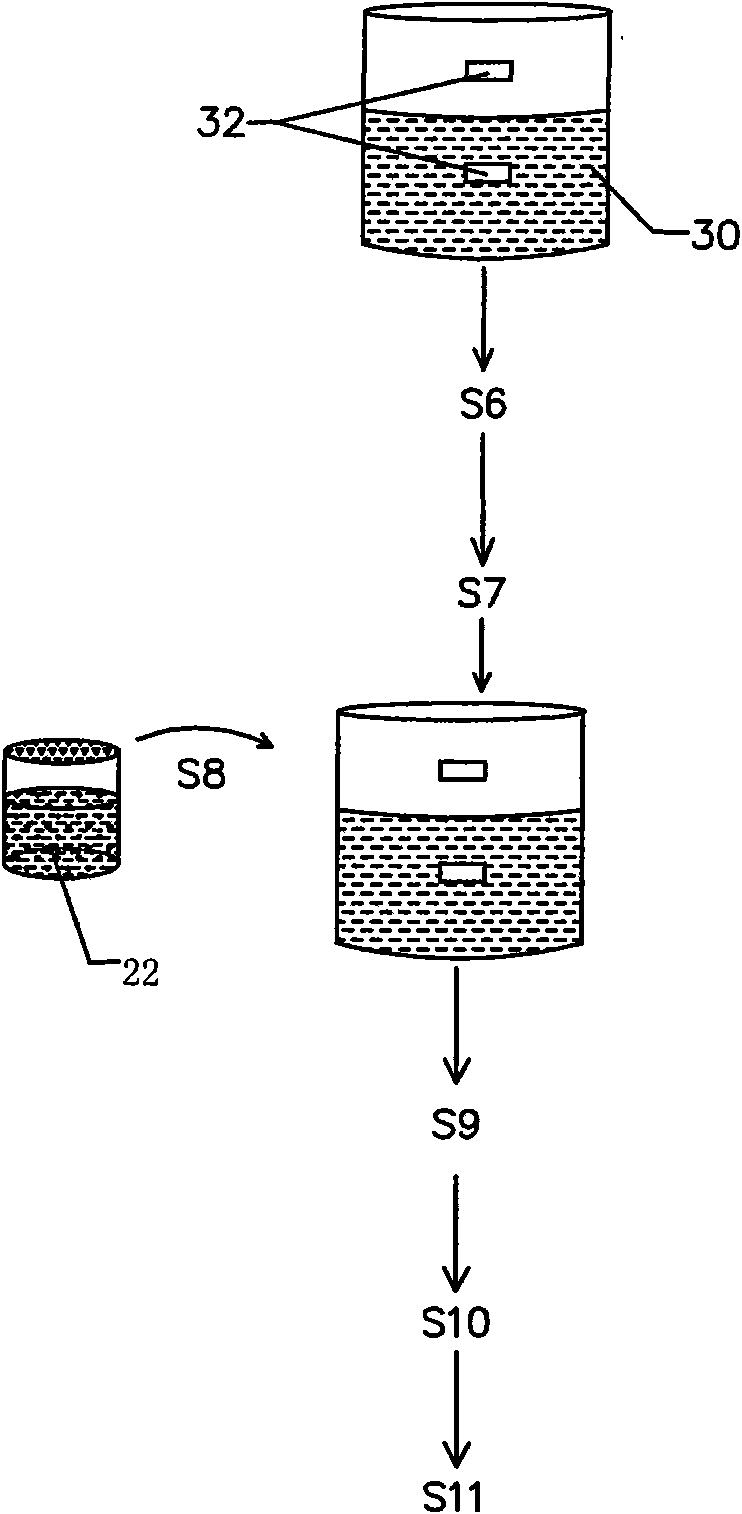

[0041] In the production of large bag cultivars of mushrooms, it is divided into three steps. First, the mother species is obtained by activating the preserved strains, which is called the activation culture step S1, and secondly, the original species is obtained by multiplying the mother species, which is called pre-production. Cultivate step S5, insert in the breathing plastic bag 30 that wheat culture medium (wet weight 6Kg) is housed at last the former seed that pre-cultivate obtains, cultivate cultivar in described wheat culture medium, be called formal cultivation step S9, After the above-mentioned breathing plastic bag 30 is loaded into the wheat culture medium, all will do autoclaving in the autoclave, then make the wheat culture medium and the breathing plastic bag 30 cool to room temperature, and then insert the original species obtained after the pre-cultivation into the The above-mentioned plastics will be described in detail with reference to the accompanying drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com