Force sensor

A force sensor and pressure technology, applied in the field of micro-electro-mechanical systems, can solve the problems of high difficulty in serialization of product specifications, failure to meet application requirements, and high manufacturing difficulty, and achieve the effects of simple structure, miniaturization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with preferred embodiment and accompanying drawing, the present invention is further described:

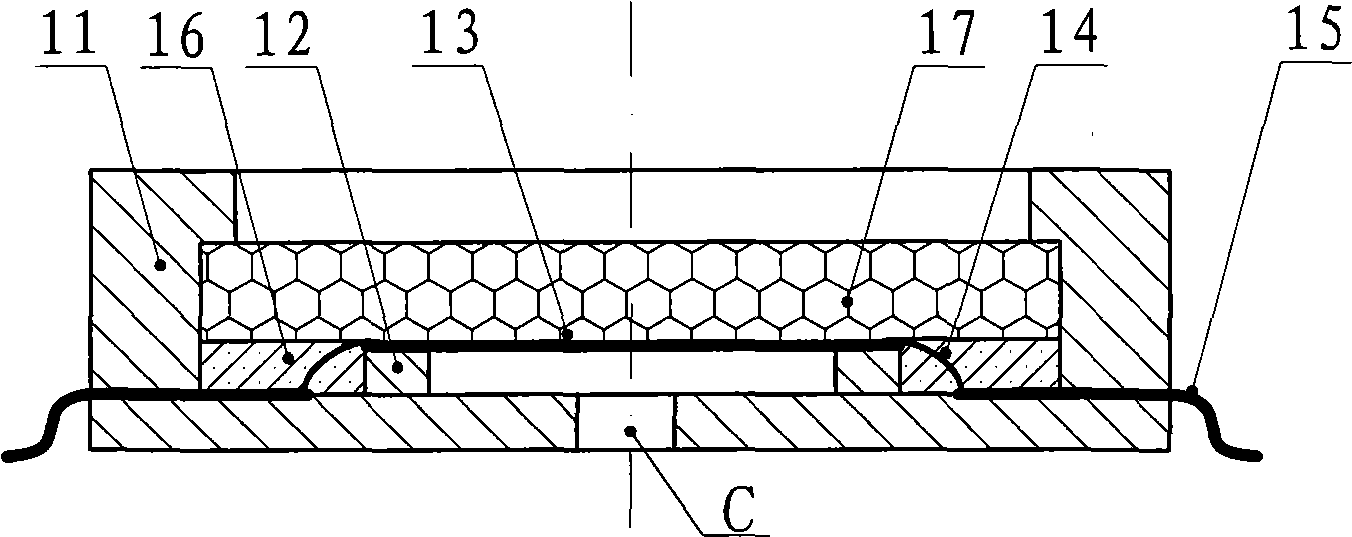

[0023] figure 1 It is a schematic cross-sectional structure diagram of an integrated circuit force sensor of the present invention; wherein, 11 is a rigid insulating open shell, and the cross-section of the outer port of the open shell 11 is smaller than the cross-section of the inner cavity; wherein, the glass base 12, the silicon film 13, and A piezoresistive bridge formed by semiconductor materials is arranged on the silicon film 13, bonding wires 14, and electrical lead pins 15 constitute the silicon film piezoresistive pressure sensitive element of the present invention; the glass base 12 is bonded to the bottom of the housing 11 , the silicon film 13 is bonded on the glass base 12, the electric lead pin 15 is bonded on the housing 11 and drawn out of the shell, and the bonding wire 14 electrically connects the piezoresistive bridge on the silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com