Hydraulic pump, oil pumping unit, oil pumping module and oil pumping system

A hydraulic pump and oil pumping technology, which is applied in the field of oil pumping modules, oil pumping units and hydraulic pumps, can solve the problems of reducing system reliability and safety, increasing energy consumption costs of oil production systems, increasing system complexity and energy consumption, etc. , to achieve the effect of eliminating potential safety hazards, simple structure, and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] see figure 1 It is a schematic structural diagram of Embodiment 1 of the oil pumping system of the present invention. The oil pumping system in this embodiment is located in a main pipeline A, and there is underground oil B entering through the oil well at the bottom of the main pipeline A. The oil pumping system mainly includes an oil pumping module, that is, a control mechanism, a hydraulic drive mechanism and an oil pumping unit. The oil pumping unit in this embodiment is composed of a hydraulic pump and an oil well pump, and the control mechanism includes a CPU and a servo motor controller. , encoders and some sensors (such as current sensors, position sensors) and corresponding peripheral circuits, the hydraulic drive mechanism includes a bidirectional pump and an AC servo motor, where the AC servo motor corresponds to the servo motor controller in the control mechanism. The main pipeline A is the fixed support part of the whole system, the components of the whole ...

Embodiment 2

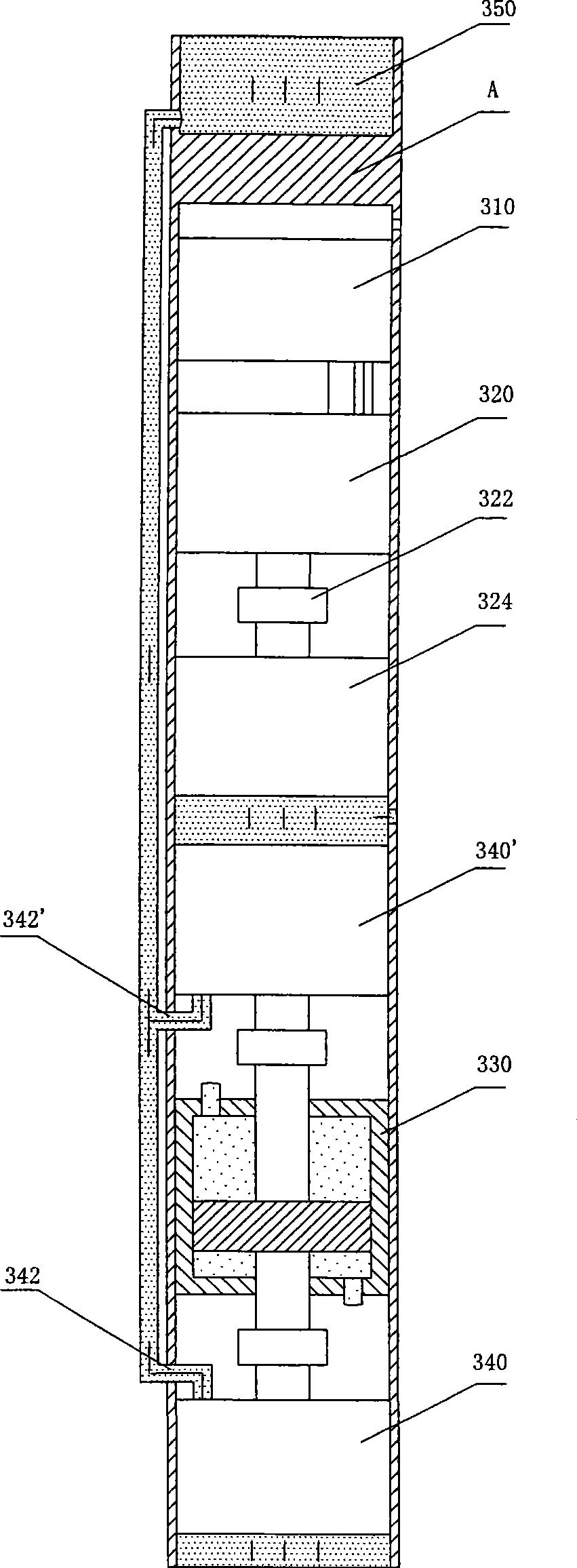

[0050] see image 3 , is a schematic structural diagram of Embodiment 2 of the oil pumping system of the present invention. Different from Embodiment 1, the oil pumping unit in the present invention has two oil pumps, 340' as shown in the figure. In this embodiment, the oil pump outlet pipes 342, 342' of the two oil pumps are combined in Together, they are delivered to the main oil outlet 350 of the oil pumping system.

[0051] Compared with Embodiment 1, this embodiment makes full use of the hydraulic pump 324, and connects the first hydraulic rod 332 with the second oil pump 340', so that when the hydraulic piston 331 of the hydraulic pump 330 reciprocates, the first 2. The second oil pump 340' works in time-sharing, which doubles the oil pumping efficiency.

Embodiment 3

[0053] see Figure 4 — Figure 6 , is a schematic structural diagram of Embodiment 3 of the oil pumping system of the present invention. In the present invention, multiple oil pumping modules can be combined to form an oil pumping system. In an embodiment, the oil pumping system is composed of three oil pumping modules. in, Figure 4 Shown is a schematic structural diagram of the oil pumping module in Embodiment 3 of the oil pumping system of the present invention, the oil pumping module is basically the same as Embodiment 1 or / and Embodiment 2, and will not be repeated here; Figure 5 Shown is the structural diagram of the main oil outlet. The main oil outlet is composed of the main oil outlet 350 and the oil inlets 351 and 352. The oil inlets can be 1, 2, 3, etc., and the figure shows 2 imported oil. Figure 6 It is the connection between the main oil outlet and each oil pumping module, the schematic diagram of the installation, the main oil outlet is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com