Iron ore sintering test method

A sintering test, iron ore technology, applied in the field of metallurgy, can solve the problems of jumping, large horizontal spacing, poor reproducibility of test results, etc., and achieve the effect of shortening test time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

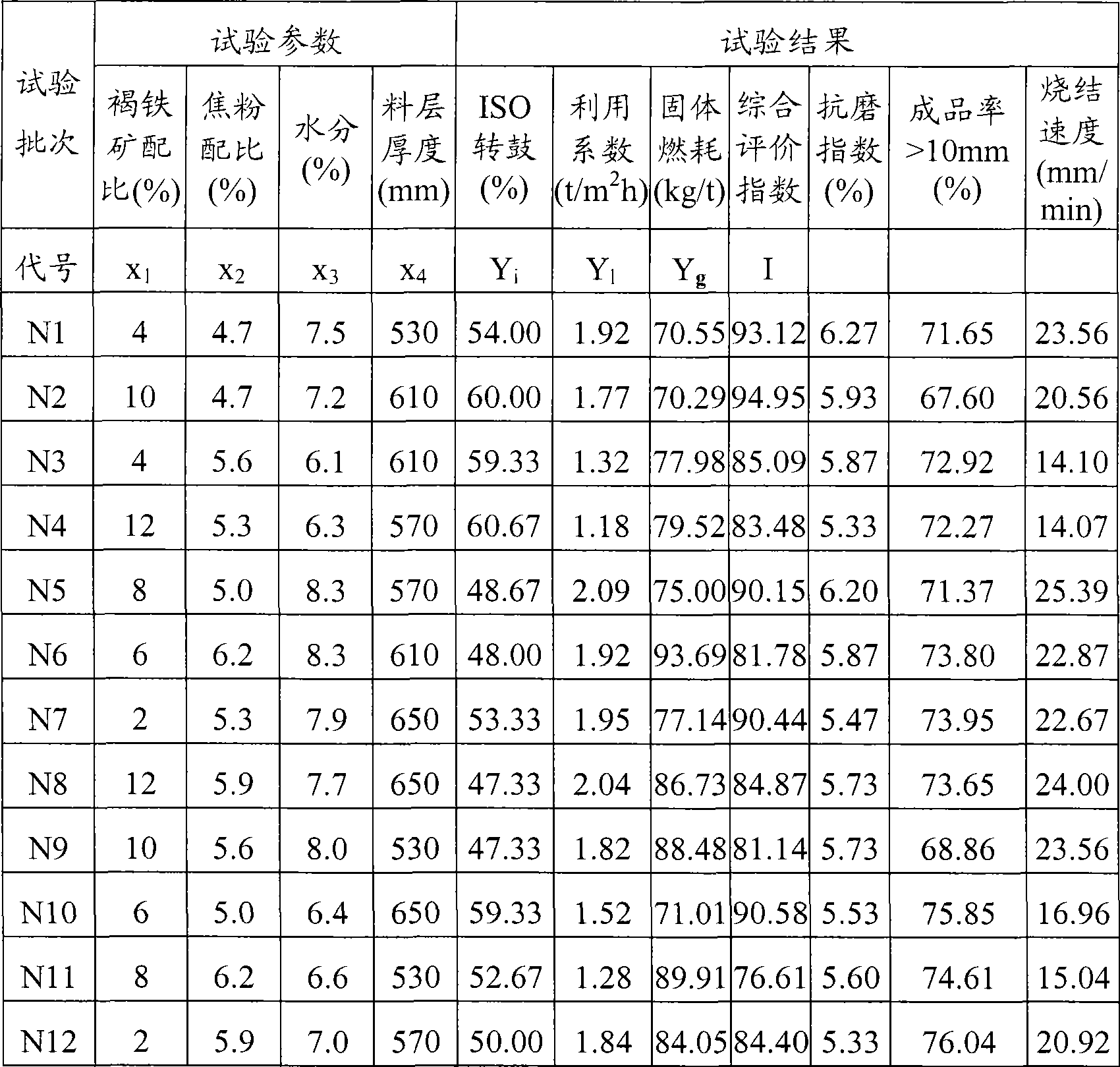

[0080] The iron ore sintering test method of the present invention will be further described below in conjunction with the limonite sintering test.

[0081] As we all know, limonite is a refractory ore containing crystal water (Fe 2 o 3· nH 2 O), the sintering performance is poor. Practices at home and abroad show that limonite has poor sintering strength, low yield and high solid fuel consumption. However, the price of limonite is relatively cheap, and the grade will increase after burning, which will help to improve the furnace grade and reduce costs, and will also help alleviate the shortage of high-grade iron ore resources.

[0082] Therefore, in view of the special characteristics of sintering, the study of limonite sintering performance must examine four factors: limonite ratio, fuel ratio, mixture moisture, and material layer thickness. If a full factorial multi-level complete test is used, the number of tests will increase dramatically or even be unacceptable. The...

Embodiment 2

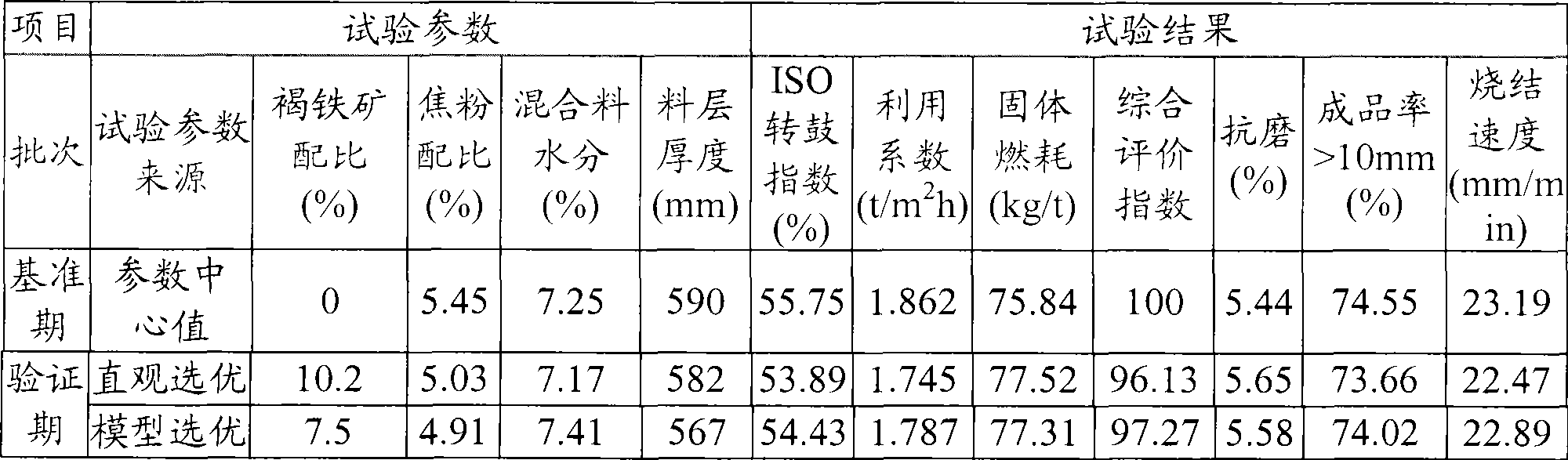

[0138] The present invention also utilizes uniform design to optimize known models. Specifically, using conventional methods for optimization is also effective for models with extreme values. For many models, there are no extreme values or small values, and it is very difficult to optimize in this case.

[0139] Uniform design is mainly used for experimental design, but uniform design can also be used to optimize parameters for experiments and production processes where the mathematical model is known. This method is called uniform design computer experiment. This kind of optimization is not to arrange experiments to study the reaction mechanism between factors, but to use this method to find parameters that meet the conditions more quickly and easily. For example, the sinter strength model that the inventor obtains by regression to a certain iron and steel plant is:

[0140] y ^ = 0.00183592 x ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com