Composite Metal Hollow Dielectric Microsphere Thermal Insulation Coating

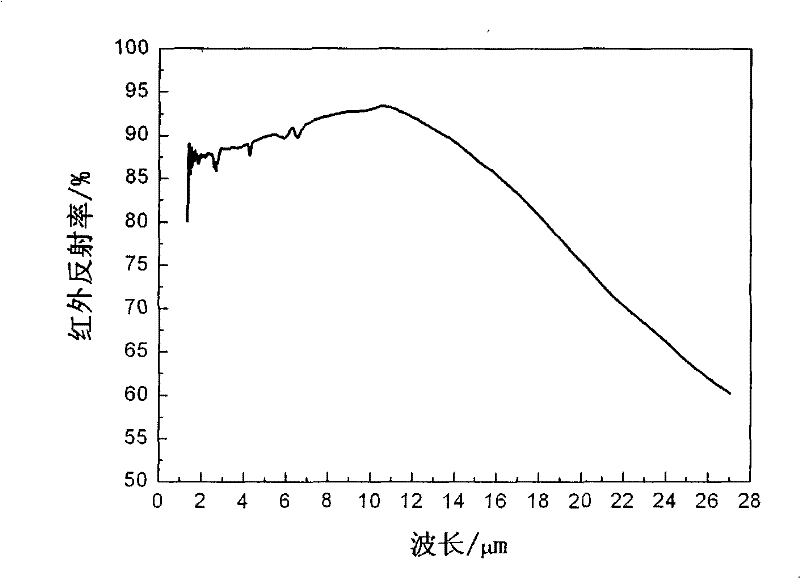

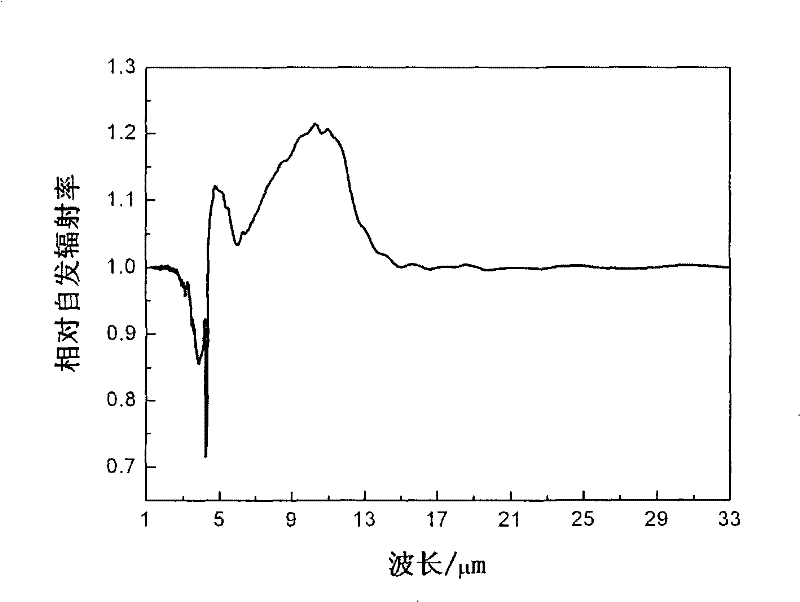

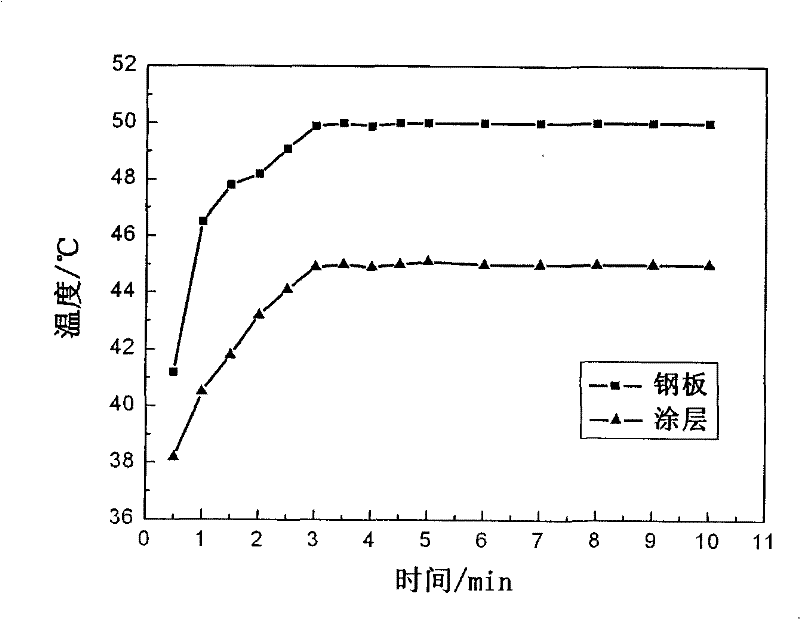

A thermal insulation coating, composite technology, applied in the direction of reflection/signal coatings, coatings, etc., to achieve the best thermal insulation, reduce spontaneous radiation, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below by embodiment and accompanying drawing, the present invention is described in further detail:

[0020] The preparation method of the present invention: take 1000ml of water-based acrylic resin with a density of 1.124g / ml, add 280g of copper-plated hollow medium microspheres, add 30g of dispersant Dispers 750W to adjust the viscosity of the coating, add 80g of film-forming aid Dowanol DPnB to improve film-forming Effect, add 16g of defoamer Foamex 1488, stir the prepared coating with a high-speed dispersion mixer for 2 hours at room temperature, then use spraying or brushing to form a coating on the surface of a 4mm thick steel plate, and dry naturally at room temperature.

[0021] The surface of the coating film formed on the surface of the metal substrate by the present invention is smooth and even, and the adhesive force is good. The metal hollow medium microspheres are closely arranged in the thermal insulation coating, and the distribution is relatively uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com