Metal-glass sealing process

A glass sealing and metal technology, applied in capacitor casing/package, electrical components, capacitor parts, etc., can solve the problems of poor high temperature sealing and poor consistency of tantalum capacitors, and achieve high insulation resistance, improved quality, and high tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

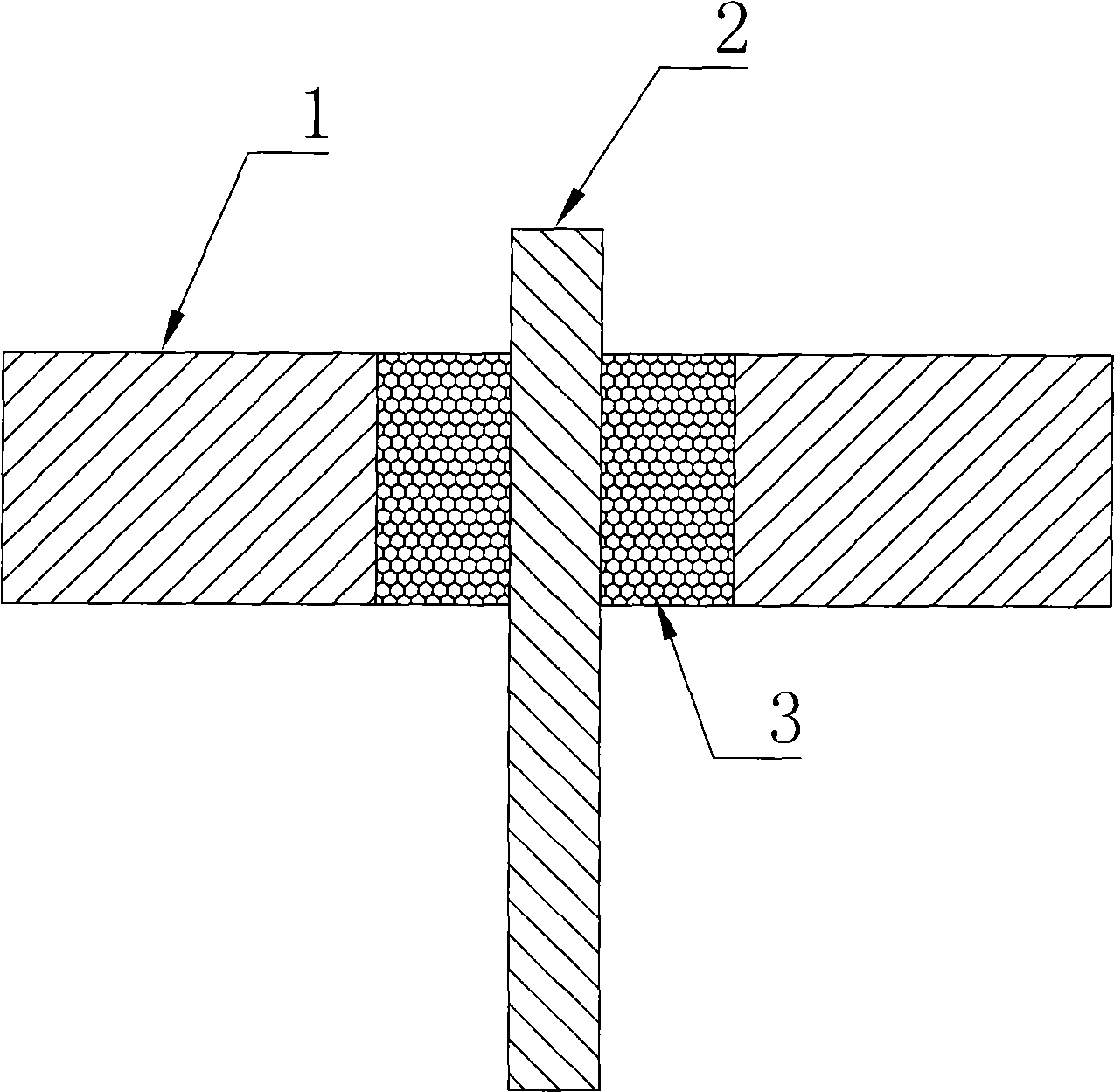

Image

Examples

Embodiment 1

[0034] The sealing process of 304 stainless steel upper cover and 4J52 alloy core post glass sealing insulator for lithium / sub-battery:

[0035] The expansion coefficient of 304 stainless steel is: 19×10 -6 / °C, the expansion coefficient of 4J52 Kovar alloy is: 9.8×10 -6 / °C, according to the new sealing method, the selected expansion coefficient is: 6.4×10 -6 / ℃ sealing glass, the specific sintering process is as follows: Now assemble the 304 stainless steel upper cover, the formed glass blank and the 4J52 alloy core column in the graphite mold, put it into the high temperature sintering furnace, turn on the mechanical pump to vacuum, and the vacuum is pumped to 10 -1 Pa, heat up to 600°C at a heating rate of 10°C / min, and continue vacuuming to make the vacuum degree of the furnace chamber ≤5.0×10 -2 Pa, and keep it warm for 30 minutes. After the heat preservation is over, turn off the vacuum pump and fill the furnace chamber with nitrogen with a purity of 99.99%. ℃, after...

Embodiment 2

[0038] Sealing process of cold-rolled steel upper cover and tantalum core column glass-sealed insulator for lithium / manganese dioxide battery:

[0039] The expansion coefficient of cold-rolled steel is: 12×10 -6 / ℃, the expansion coefficient of metal tantalum is: 6.5×10 -6 / °C, according to the new sealing method, the selected expansion coefficient is: 3.4×10 -6 / °C sealing glass, the specific sintering process is as follows: Now assemble the cold-rolled steel upper cover, the formed glass billet and the tantalum core column in the graphite mold, put them into the high-temperature sintering furnace, turn on the mechanical pump to vacuum, and the vacuum is pumped to 10 -1 Pa, heat up to 550°C at a heating rate of 10°C / min, and continue vacuuming to make the vacuum degree of the furnace chamber ≤5.0×10 -2 Pa, and keep it warm for 30 minutes. After the heat preservation is over, turn off the vacuum pump and fill the furnace chamber with nitrogen with a purity of 99.99%. When th...

Embodiment 3

[0042] The sealing process of the tantalum upper cover and the tantalum stem glass-sealed insulator for high-energy hybrid tantalum capacitors:

[0043] The expansion coefficient of tantalum is: 6.5×10 -6 / °C, according to the new sealing method, the selected expansion coefficient is: 3.4×10 -6 / °C sealing glass, the specific sintering process is as follows: Now assemble the tantalum upper cover, the formed glass blank and the tantalum core column in the graphite mold, put them into the high-temperature sintering furnace, turn on the mechanical pump to evacuate, and the vacuum is evacuated to 10 -1 Pa, heat up to 600°C at a heating rate of 10°C / min, and continue vacuuming to make the vacuum degree of the furnace chamber ≤5.0×10 -2 Pa, and keep it warm for 30 minutes. After the heat preservation is over, turn off the vacuum pump and fill the furnace chamber with argon gas with a purity of 99.99%. When the pressure in the furnace chamber is 1Pa, turn off the gas filling valve a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of expansion | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com