The manufacturing method of construction materials using waterworks sludge

A technology for sewage treatment plants and building materials, which is applied in the production of ceramic materials, sustainable waste treatment, and applications. It can solve the problems of high raw material costs and impractical use, and achieve good sound insulation, strong resistance, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

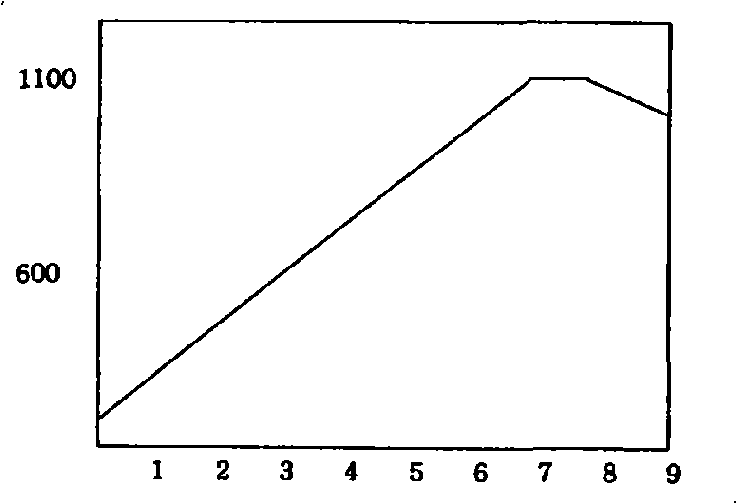

Image

Examples

specific Embodiment approach

[0041] [38] Next, the present invention will be described in detail with reference to examples.

[0042] [39] Examples

[0043] [40] The first process (treatment of primary processing water purification sludge)

[0044] [41] put 1 ton of sludge produced in a sewage purification plant in a rotary kiln and fired it at 800°C-850°C for 3-5 hours in order to completely remove water and organic matter in the sludge to produce 80- 500 kg of primary processing water purification sludge.

[0045] [42] The second process (preparation of green body)

[0046] [43] 22 kg of primary processing water purification sludge, 18 kg of clay, 36 kg of gypsum powder, 14 kg of wax stone and 10 kg of dolomite were mixed, then ground by a ball mill and passed through a 200-mesh sieve to produce a residual amount Less than 1% green body.

[0047] [44] The third process (manufacturing building materials)

[0048] [45] Mix 31.5 kg of green body prepared in the second process above, 2.3 kg of calcined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com