Lamp tube device with electric connecting sleeve of winding body and light source module

A light source module and electrical connection technology, which is applied to the parts of gas discharge lamps, lighting devices, light source fixing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

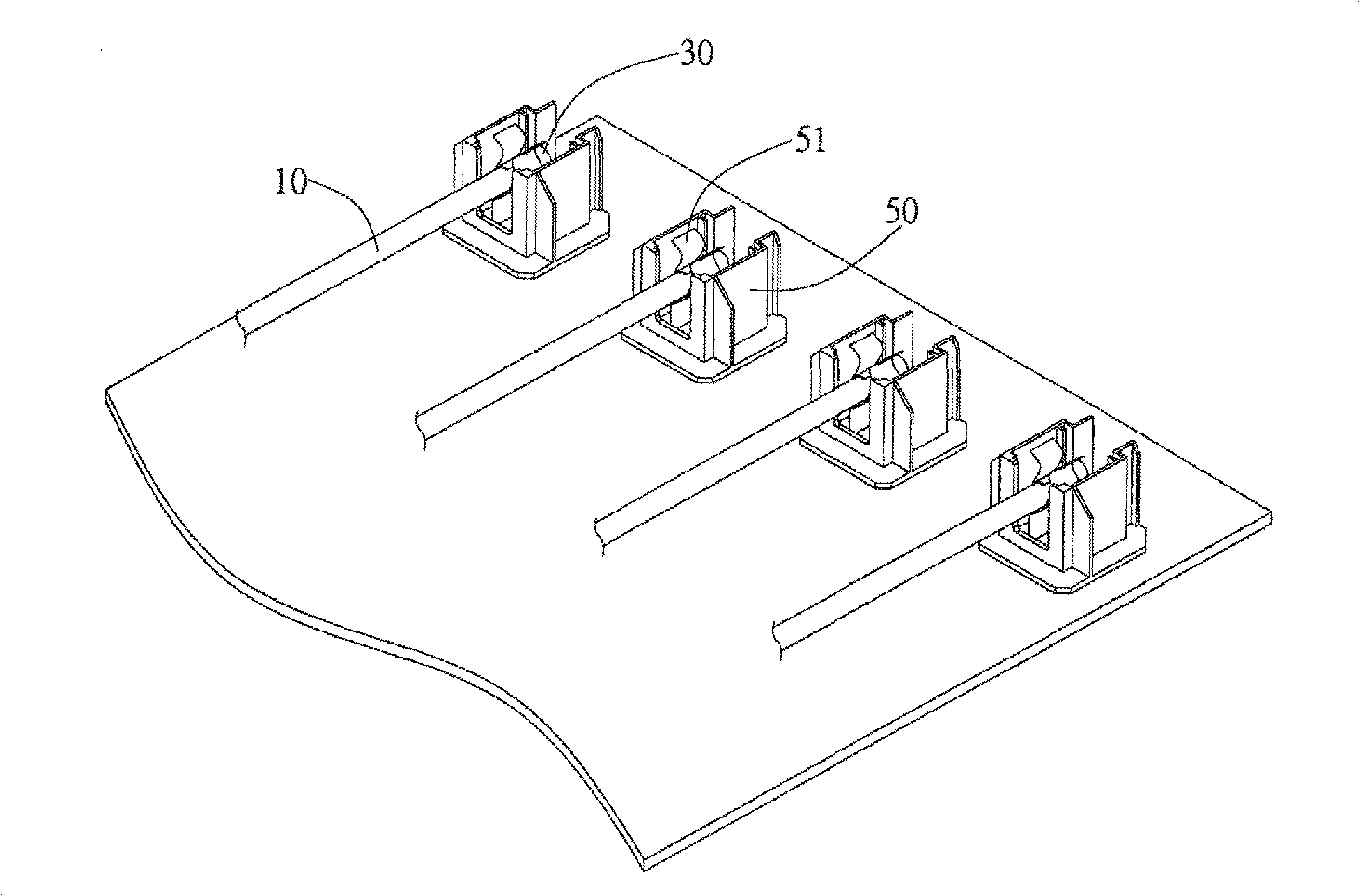

[0052] The invention provides a lamp device and a light source module using the lamp device. In a preferred embodiment, the lamp device and the light source module of the present invention are applied in a backlight module to provide the light source required by the backlight module. However, in different embodiments, the lamp device and the light source module can also be used in other electronic devices as the required light source. In addition, the backlight module using the lamp device and the light source module of the present invention can be applied in liquid crystal displays to provide the light required by the liquid crystal panel.

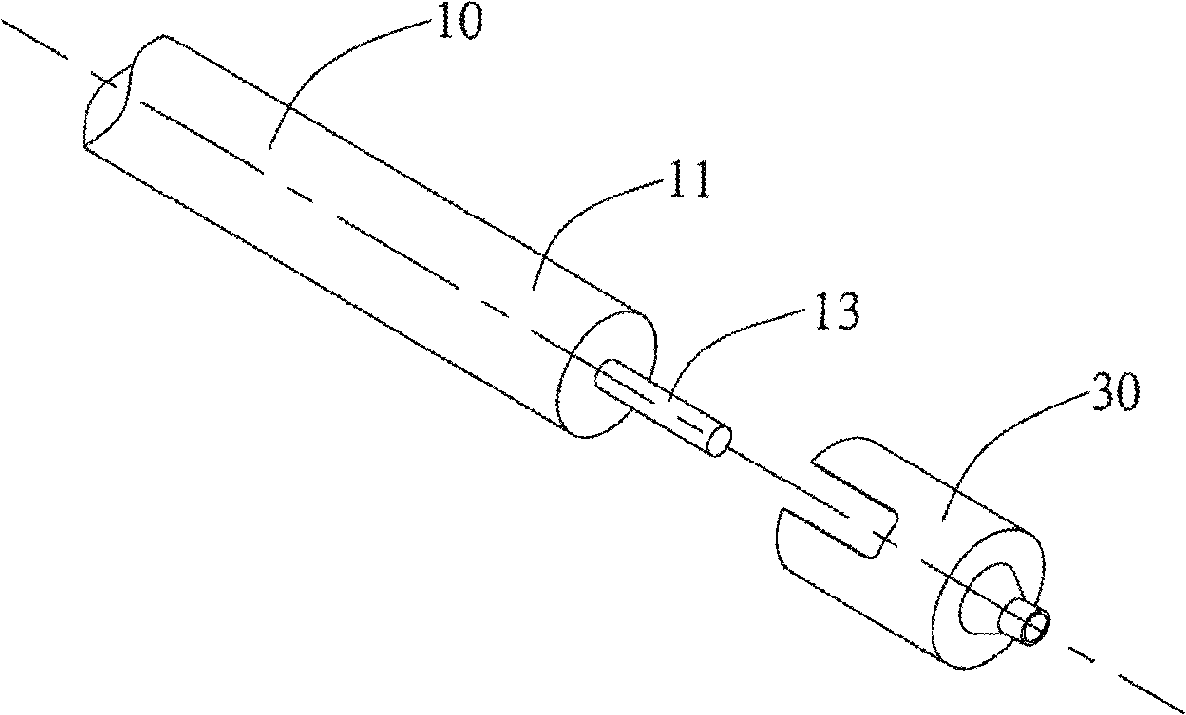

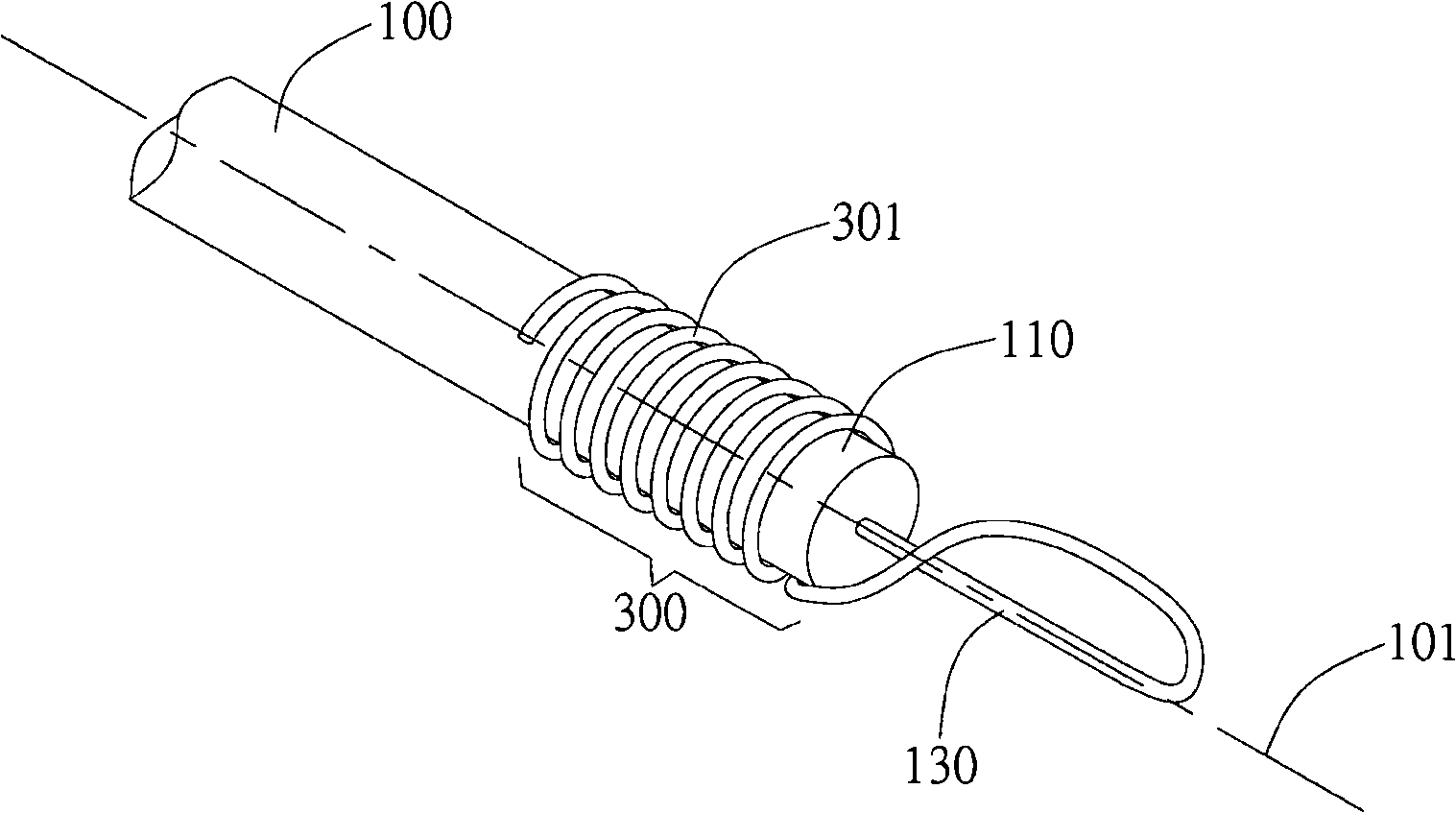

[0053] Such as Figure 2a As shown, the lamp device of the present invention includes a lamp body 100 and an electrical connection sleeve 300 of the wound body. The lamp body 100 preferably comprises a cold cathode lamp (CCFL) or other types of lamps. The winding body electrical connection sleeve 300 is preferably wound with a metal wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com