Separation method of solid fermentation fungal spore

A fungal spore and separation method technology, which is applied in the field of separation of solid fermentation fungal spores, can solve the problems of spore escape, affect the purity of spore powder, and difficult separation, and achieve the effect of simple structure, complete separation, and complete purification and filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

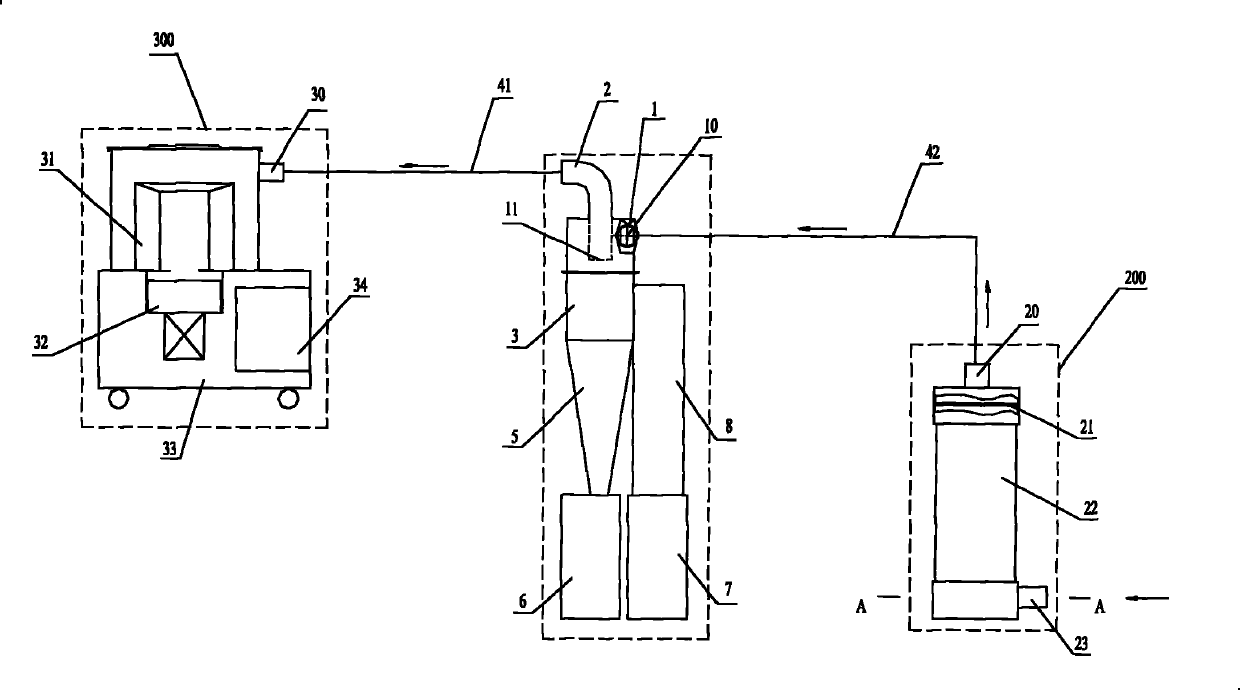

[0025] Embodiment 1, a kind of spore separation device, such as Figure 1 to Figure 4 As shown, the applicant has applied for the invention patent "cyclone separator and spore separation device with the cyclone separator" on the same day, and the details are as follows:

[0026] It includes a cyclone, a cyclone feeder assembly 200 and a fan assembly 300 .

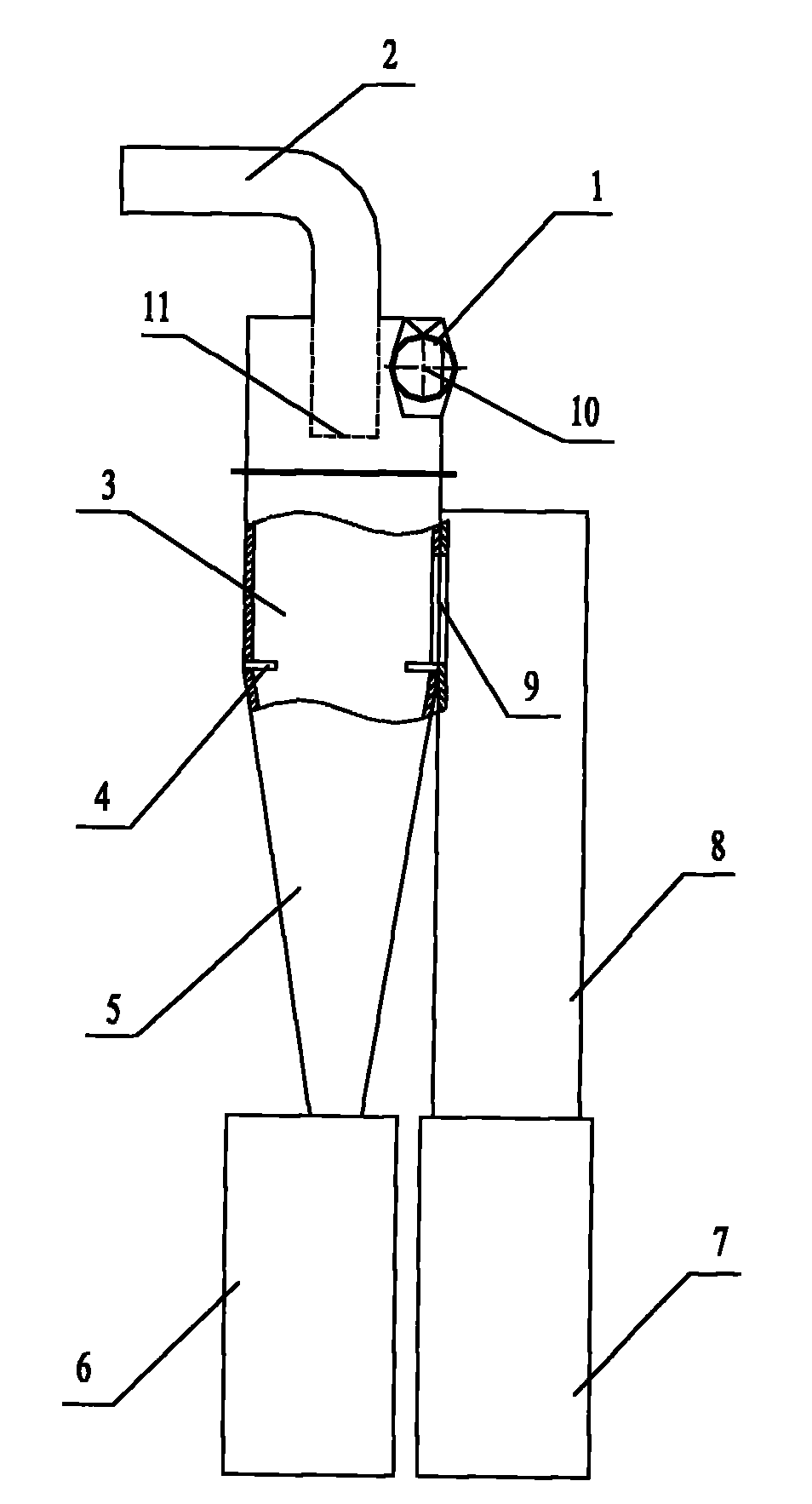

[0027] The cyclone separator includes a hollow main separator and a hollow secondary separator 8 . The main separator includes a connected cylindrical body 3 and a cone 5, the cylindrical body 3 is located directly above the cone 5, that is, the central axis of the cylindrical body 3 and the central axis of the cone 5 overlap; the cone 5 is It is an inverted cone with a big upper and a small lower, and the upper end of the cone 5 is connected with the cylindrical body 3 . The main separator and the secondary separator 8, which are composed of the cylindrical body 3 and the cone 5, are made of stainless steel.

[0028] An...

Embodiment 2

[0032] Embodiment 2, a kind of solid fermentation fungal spore separation method, utilizes the above-mentioned spore separation device, and its working process is as follows:

[0033] 1. Dry the spore-containing solid medium to a moisture content of ≤9% (this percentage is a weight percentage), then disperse it into particles of 1-10 mm size; then put the above-mentioned particles into a clean container to make the container Connected to the feed port 23.

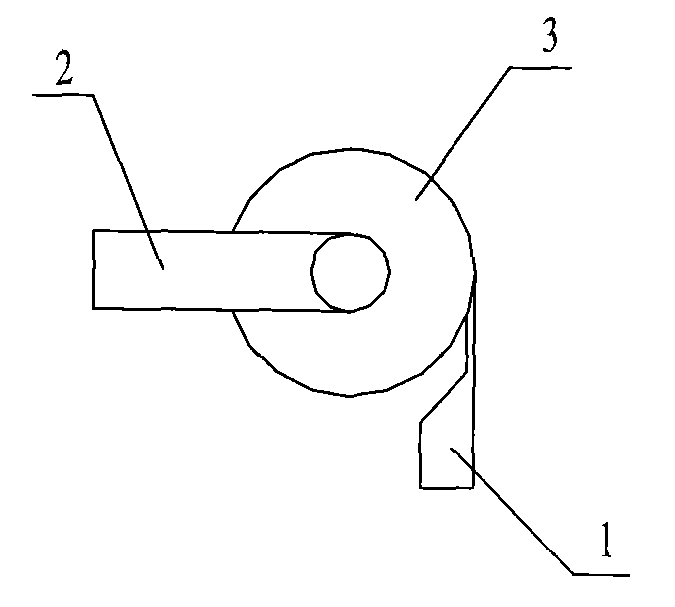

[0034] The fan 32 is activated by the control element 34, and the above-mentioned particles enter the swirl feeder 22 in a tangential direction through the feeding port 23 with the air flow through the suction force generated by the fan 32. The air flow rate can be changed through the air volume regulator 10, and the air flow rate is generally controlled at 8.5-44.5 m / s.

[0035] 2. The particles rotate at high speed along the cylinder wall of the swirl feeder 22 and rub against each other in the swirl feeder 22. After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com