Hydrocracking tail oil ultra-deep adsorbent desulfurizing and denitrifying method

A technology of hydrocracking tail oil and deep adsorption, which is applied in the field of petroleum refining, and can solve problems such as difficulties in industrial promotion and application, increased investment costs, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

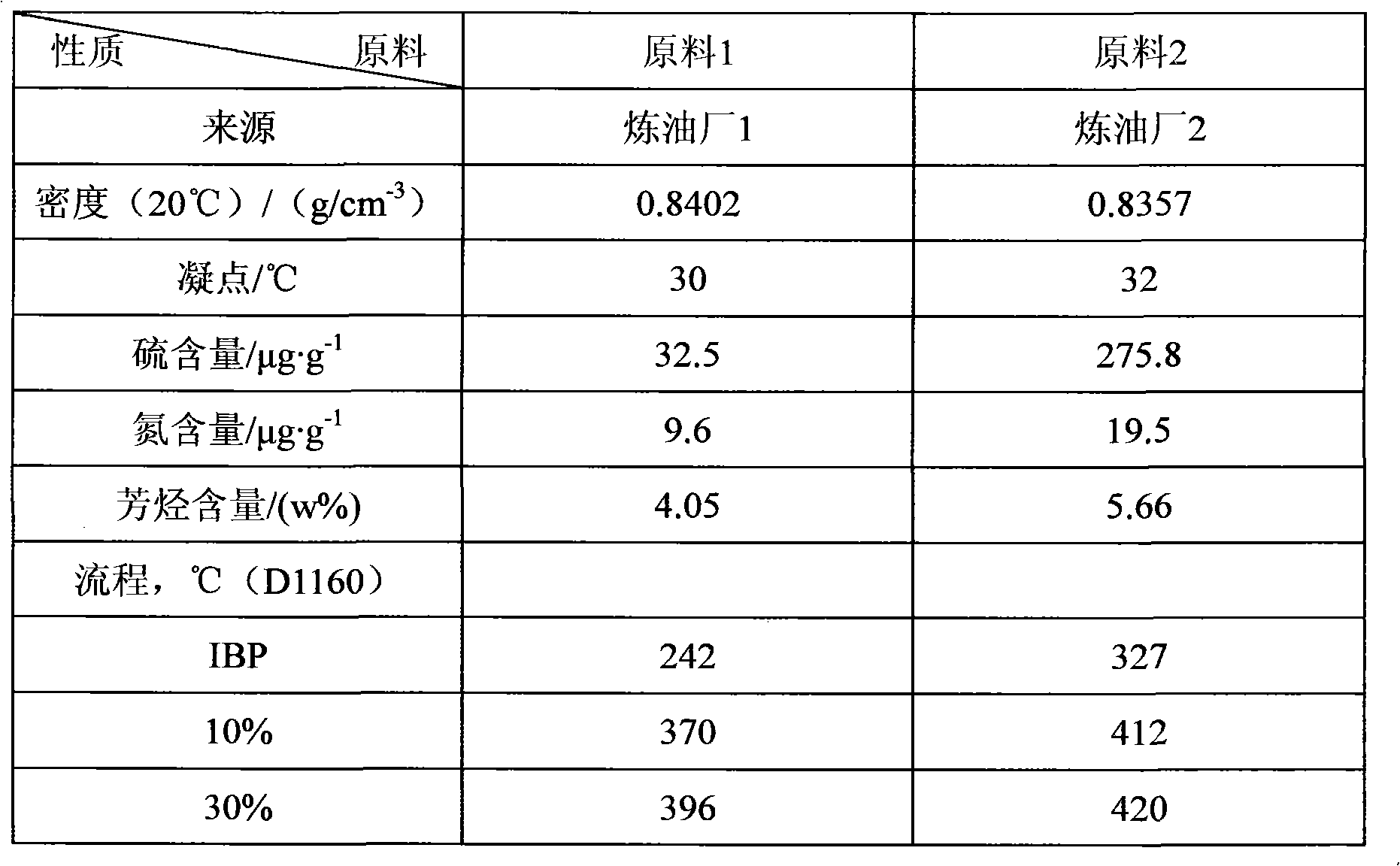

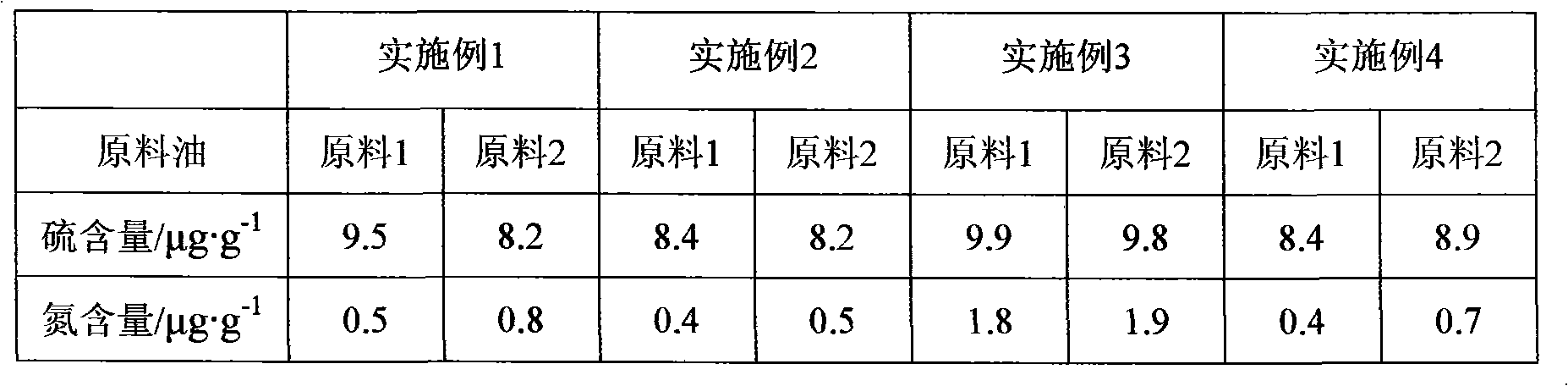

[0018] 10ml adsorption desulfurization agent (mass percentage is composed of: sodium hydroxide 10%, copper nitrate 5%, carrier powder 80%, water 5%) and 10ml adsorption denitrification agent (mass percentage is composed of: sulfuric acid 5%, iron sulfate 10% %, carrier powder 78%, water 7%) were loaded on a 20ml fixed-bed reactor, and a continuous dynamic adsorption experiment was carried out using the hydrocracking tail oil of two domestic oil refineries as raw materials. The adsorption process conditions were adsorption temperature 100°C, Pressure, space velocity 1.0h -1 , properties of hydrocracking tail oil and properties of refined oil after adsorption desulfurization and denitrogenation after reaction for 50h are shown in Table 1 and Table 2.

Embodiment 2

[0020] Same as Example 1, except that the adsorption temperature is changed to 280°C, and the properties of the product oil after adsorption desulfurization and denitrogenation are shown in Table 2.

Embodiment 3

[0022] Same as Example 1, just change the adsorption space velocity to 2.8h -1 , the properties of the product oil after adsorption desulfurization and denitrogenation are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com