Developing device and process cartridge

一种显影装置、显影剂的技术,应用在显影剂、仪器、应用电荷图形的电记录工艺等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0146] (Manufacturing example and working example)

[0147] The present invention will be described more specifically below by referring to Production Examples and Examples. It should be noted that the parts of the following compounds represent parts by mass.

[0148] Manufacture of magnetic powder

[0149]

[0150] In an aqueous solution of ferrous sulfate, 1.0 to 1.1 equivalents of caustic soda solution relative to the iron element, 1.5% by mass of sodium hexametaphosphate when the phosphorus element is converted to the iron element, and 1.5% by mass when the silicon element is converted to the iron element 1.5% by mass of sodium silicate hydrate to prepare an aqueous solution containing ferrous hydroxide.

[0151] While maintaining the pH at 9, air was blown into the obtained aqueous solution, and oxidation was performed at 80 to 90° C. to prepare a seeded slurry.

[0152] In this slurry, an aqueous solution of ferrous sulfate is added so that the amount of alkali ini...

Embodiment 1

[0199] The cartridge (1) in Table 3 was used for the developing device for evaluation. A cartridge (1) was filled with the magnetic toner (1) of Table 2, and inserted into a laser beam printer-LBP-1210 (manufactured by Canon Inc.). A printing test of 1000 image output was performed at normal temperature and humidity (23° C., 60% RH). As an image for durability, an A letter (8 dots) image with a coverage rate of 4% was used. Use 75g / m 2 A4 size paper is used as the recording medium.

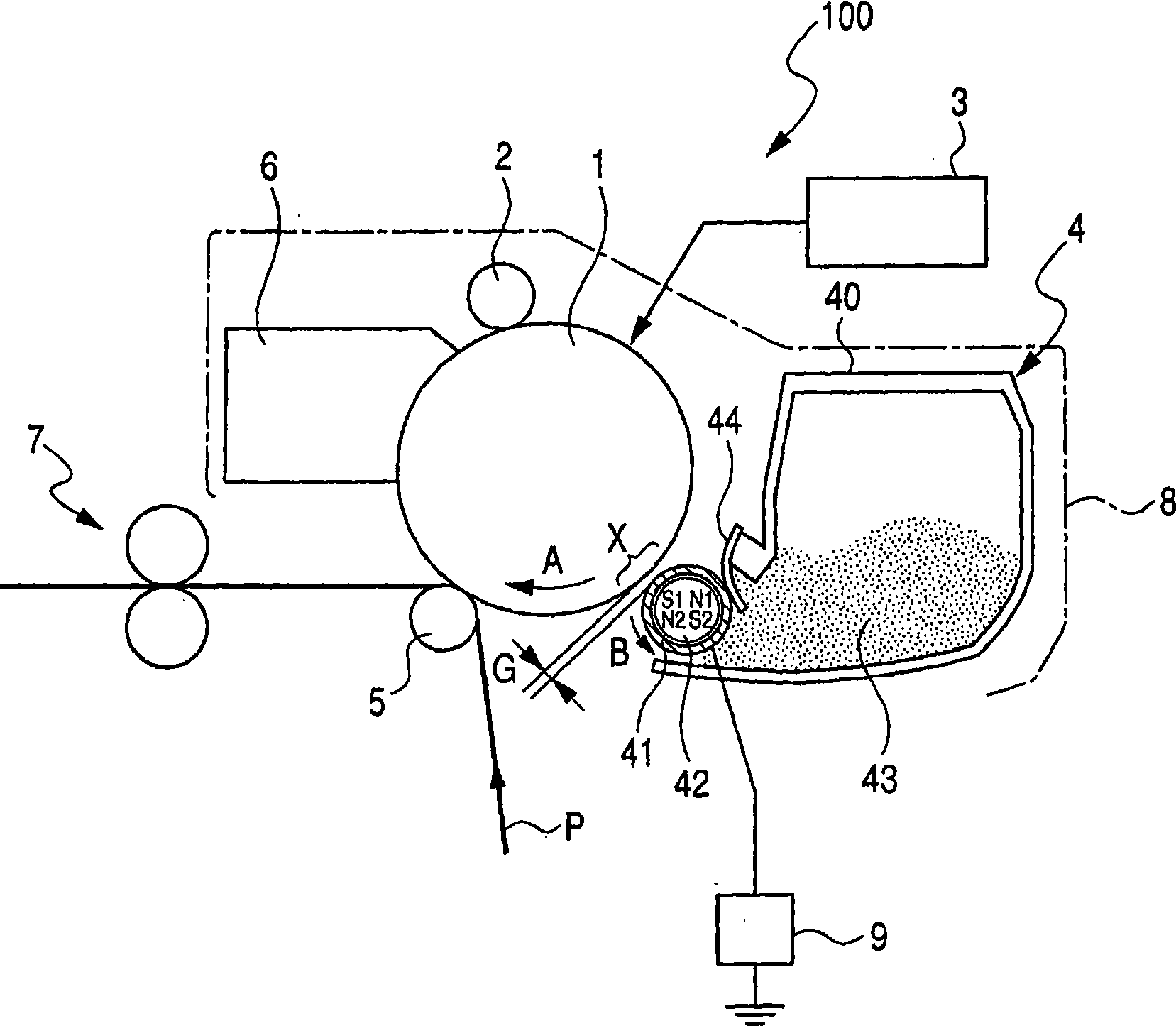

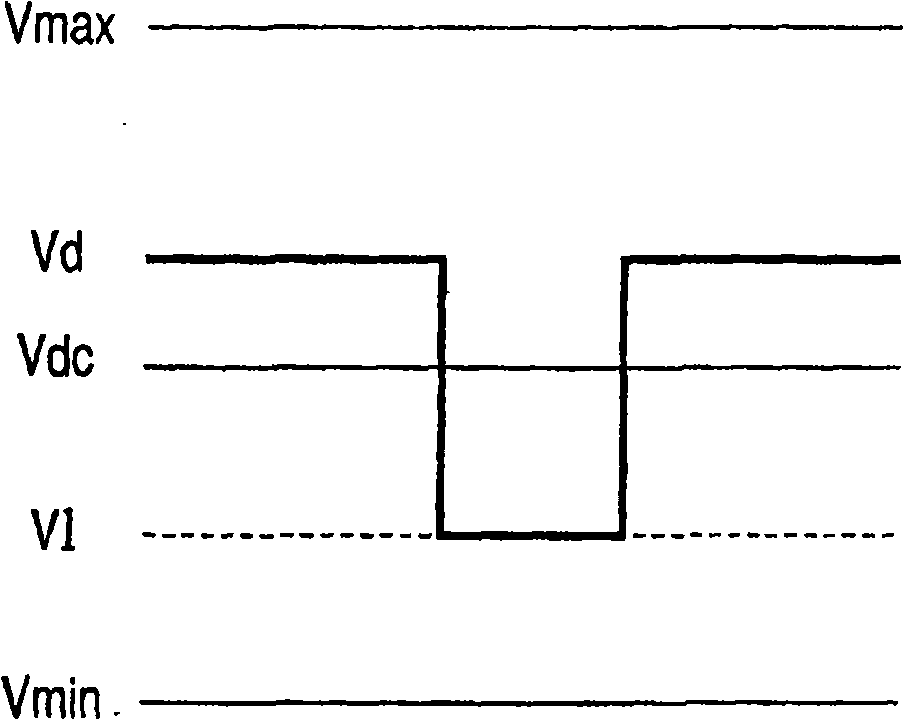

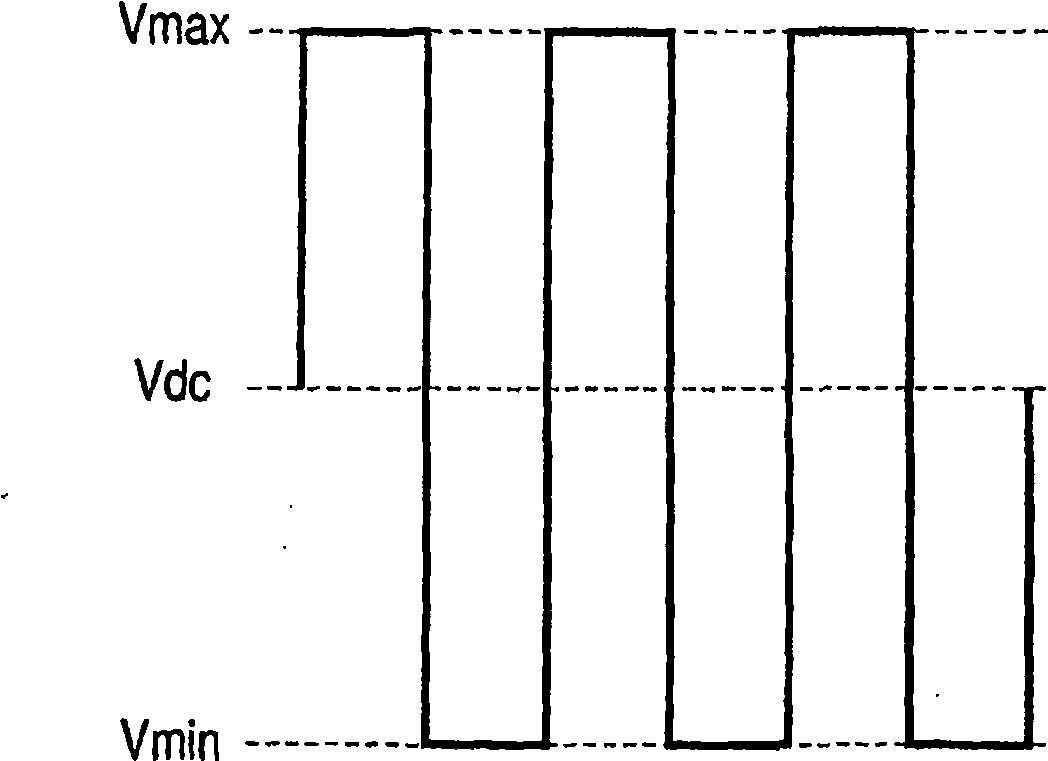

[0200] The latent image potential on the photosensitive drum 1 was set to be Vd = -600 (V) and V1 = -150 (V). The developing bias potential was set to Vpp=1600 (V). As provisional DC bias components, Vdc=-450(V) and (Vmax=-1250(V) and Vmin=+350(V)) are set. Before the printing test of 1000 image output, the Vdc value was adjusted so that the measured value of a 5 mm square black image printed in the center and four corners of the printing paper by a Macbeth reflection densitometer (manufactur...

Embodiment 2 and 3

[0215] As a developing device for evaluation, the cartridge (1) shown in Table 3 was used and filled with the magnetic toners (2) and (5) shown in Table 2 and a printing test was performed as in Example 1. Table 4 shows the results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com