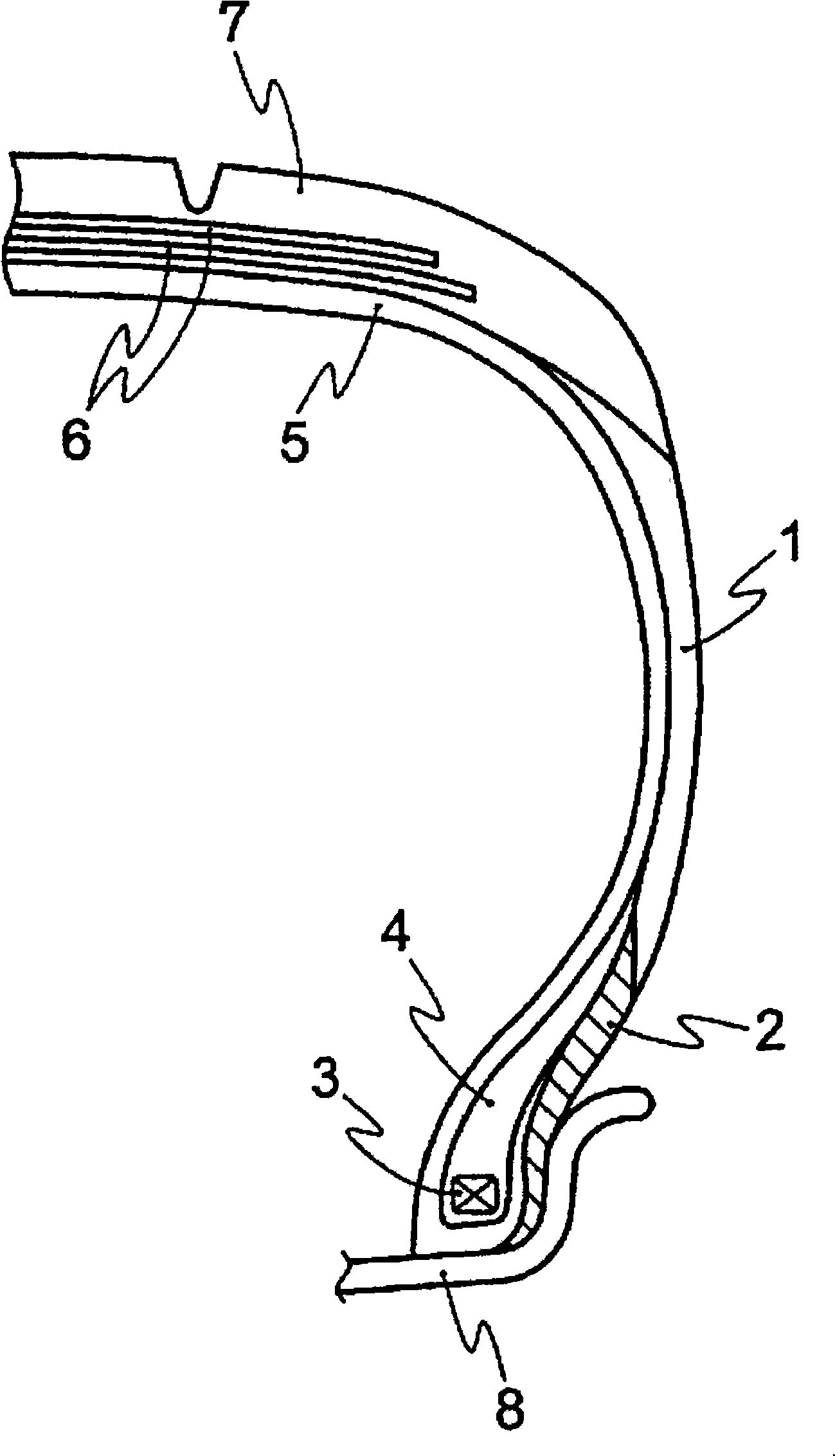

Rubber composition for clinch apex and pneumatic tire with clinch apex utilizing the same

A rubber composition and rubber strip technology, which is applied to tire parts, bead, transportation and packaging, etc., can solve problems such as increased mixing process, difficult processing, edge cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

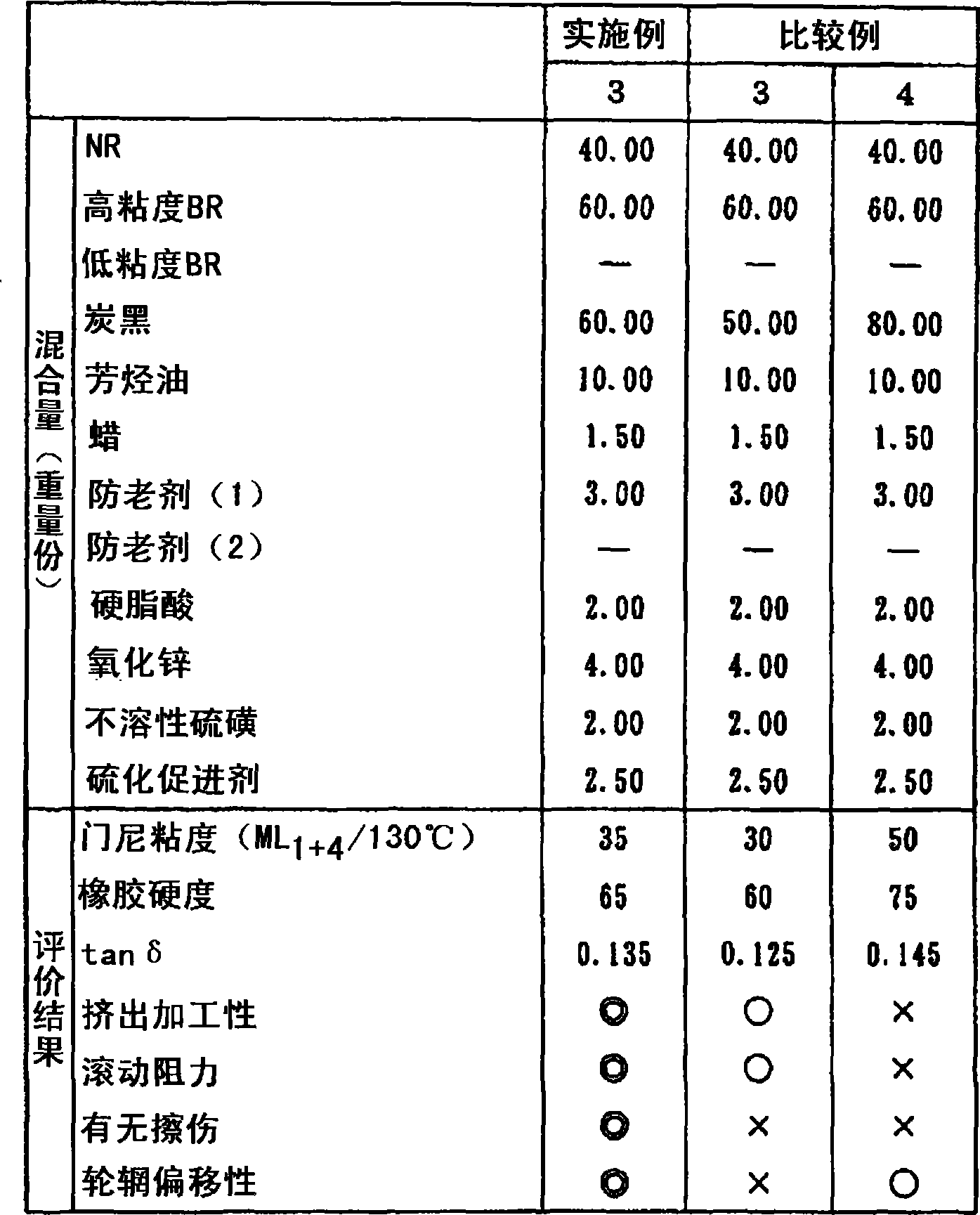

Embodiment 1~3 and comparative example 1~4

[0058] According to the formulations shown in Table 1 and Table 2, the chemical reagents except the insoluble sulfur and the vulcanization accelerator were kneaded for 4 minutes using a Banbury internal mixer under the condition of 160° C. to obtain a kneaded product. Next, insoluble sulfur and a vulcanization accelerator were added to the obtained kneaded product, and kneaded at 100° C. for 5 minutes using an open mill to obtain an unvulcanized rubber composition. Then, under the condition of 170° C., the obtained unvulcanized rubber composition was vulcanized on a plate for 15 minutes to obtain the vulcanized rubber compositions of Examples 1-3 and Comparative Examples 1-4.

[0059] (Mooney viscosity)

[0060] Using the above-mentioned unvulcanized rubber composition, according to JIS K 6300 "Unvulcanized rubber-Physical properties-Part 1: Determination of viscosity and scorch time from Mooney viscosity", using a Mooney viscosity tester, after 1 minute Preheating and heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com