Co-extruded product

A co-extrusion and product technology, which is applied in baked food, food preparation, food forming, etc., can solve the problems of restricting the degree of expansion and obstruction at the exit of the die, and achieve the effect of stable filler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

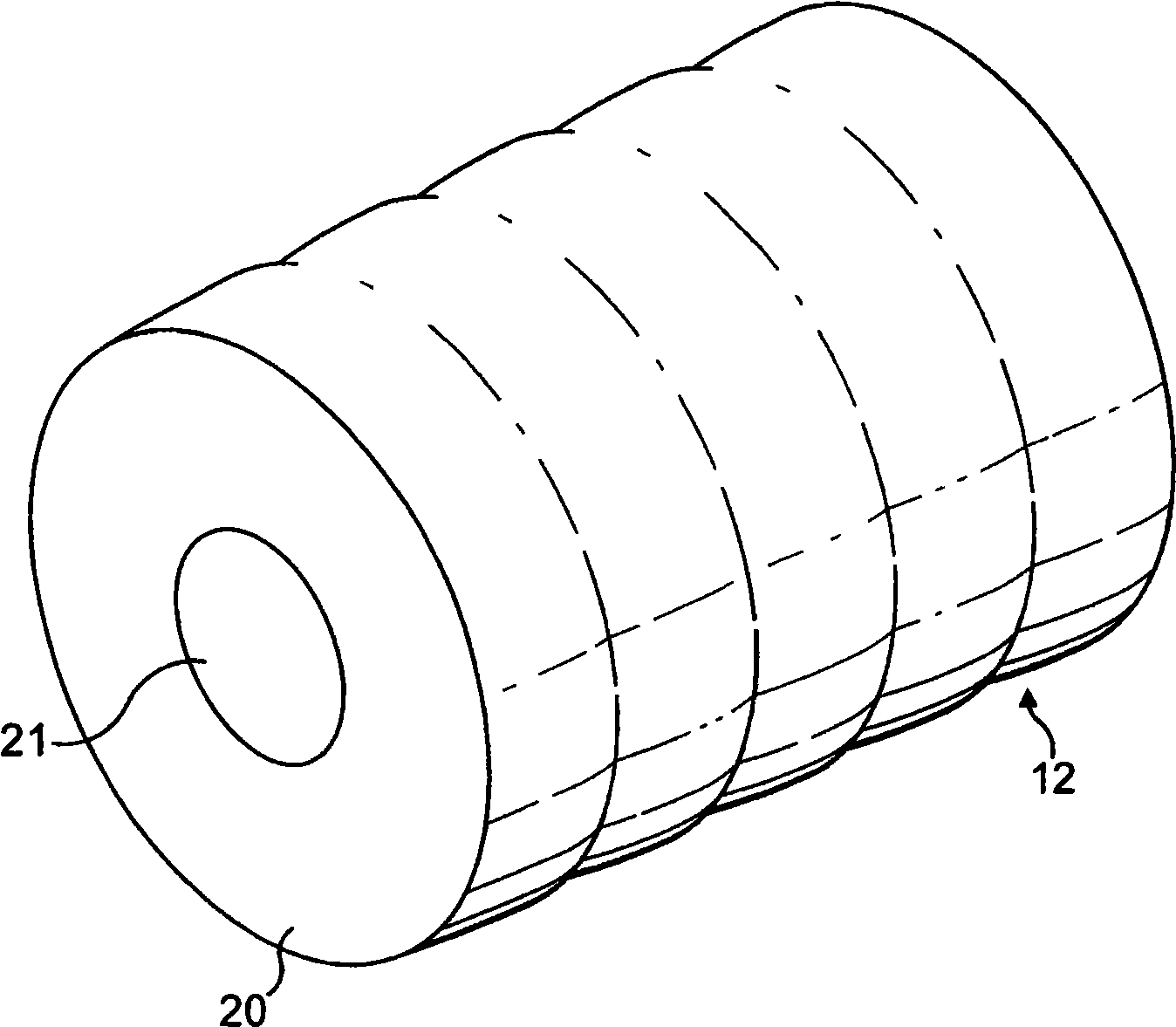

[0060] The corn-based cereal is cooked at a temperature of 150°C and a creamy filling comprising vegetable oil (which is completely liquid at 20°C), cocoa powder, sugar, starch and vanilla flavoring is fed into the cooking extruder. Round super puffed sticks were coextruded and traveled on a conveyor belt at a speed of 80 m / min. The strips were cut and passed through a tube of length 10 cm.

[0061] image 3 and Figure 4 The obtained segments are shown. In this particular example, the segment (12) has a diameter of 18 mm and a length of 35 mm. The filler accounts for 60% of the whole product, and the diameter of the filler is 6.5mm. This product has a density of 75 g / l.

[0062] The product was then dried to a moisture content of 2.5% and coated. This product is stored and sent to the packaging process step.

example 2

[0064] The yield point of the filler samples of Example 1 was measured using the equipment TextureAnalyser HDplus from Stable Micro Systems (Godalming, Surrey, UK) equipped with a 250 kg load cell and extrusion assembly. The extrusion assembly consisted of a cylindrical plastic barrel with an inner diameter of 48 mm and an inner depth of 103 mm, with a circular countersunk orifice, ie, a mold, at the bottom of the barrel with an inner diameter of 14 mm and an outer diameter of 10 mm. The orifice has a depth of 4 mm. The filling is sent to this barrel and the filled barrel is placed in the oven at 80°C for 20 minutes. At the end of this time, the bucket is quickly placed in the testing machine and the filler is forced through the die by the movement of the punch down into the bucket. The punch featured at its point of contact with the filler a transverse disc with a thickness of 5 mm and a diameter of 40 mm. The motion rate employed was 10 mm / s.

[0065] From the variation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com