Packing machine manipulator

A technology of manipulators and cartoning machines, which is applied in the field of packaging, can solve the problems of broken bottles and low production capacity, and achieve the effects of stable packing, high production capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

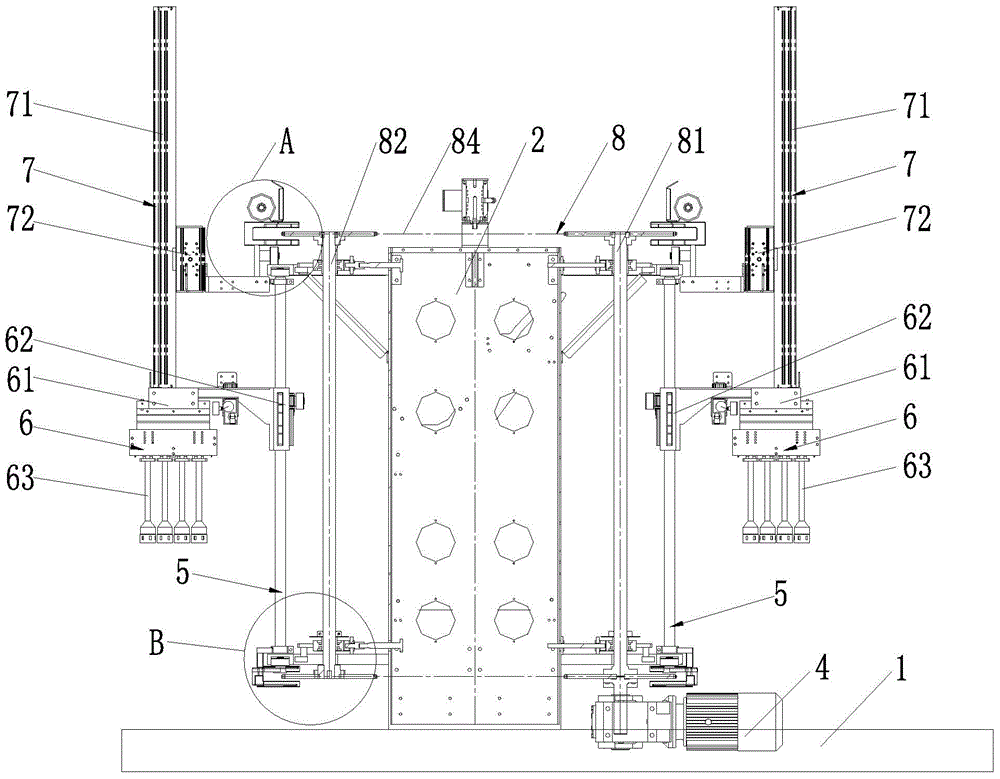

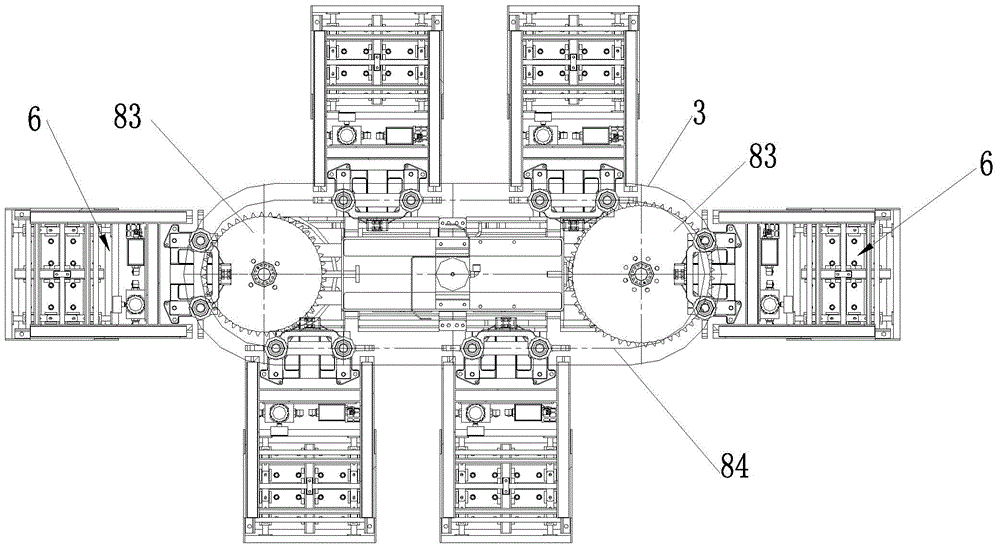

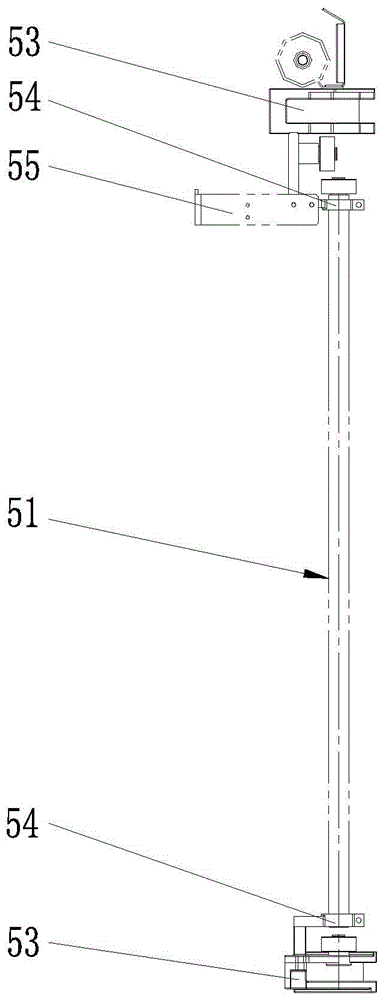

[0021] see picture 1 As shown, a manipulator for a case packing machine is installed on the frame of the case packing machine 1 superior. Includes rack mounted 1 center tower 2 , fixed on the central tower 2 Multiple circular guide rails parallel to each other on the 3 , Installed on the central tower 2 on the circular guide rail 3 Multiple swivel arms sliding on rails 5 , Can be lifted and installed on each swivel arm 5 The gripper assembly used to grab and place the bottle to be packed 6 , the manipulator also includes a rotating arm that can drive 5 Along the circular rail 3 Sliding gear. In this embodiment the ring guide 3 There are two, located in the central tower 2 top and bottom ends. see picture 2 As shown, the swivel arm has 6 strips on two ring rails 3 between, respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com