Support tie bar for cushion-type protection structure

A technology of support system and cushion, applied in coastline protection, infrastructure engineering, marine engineering, etc., can solve the problems of low quality, deformation, and a lot of manual work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

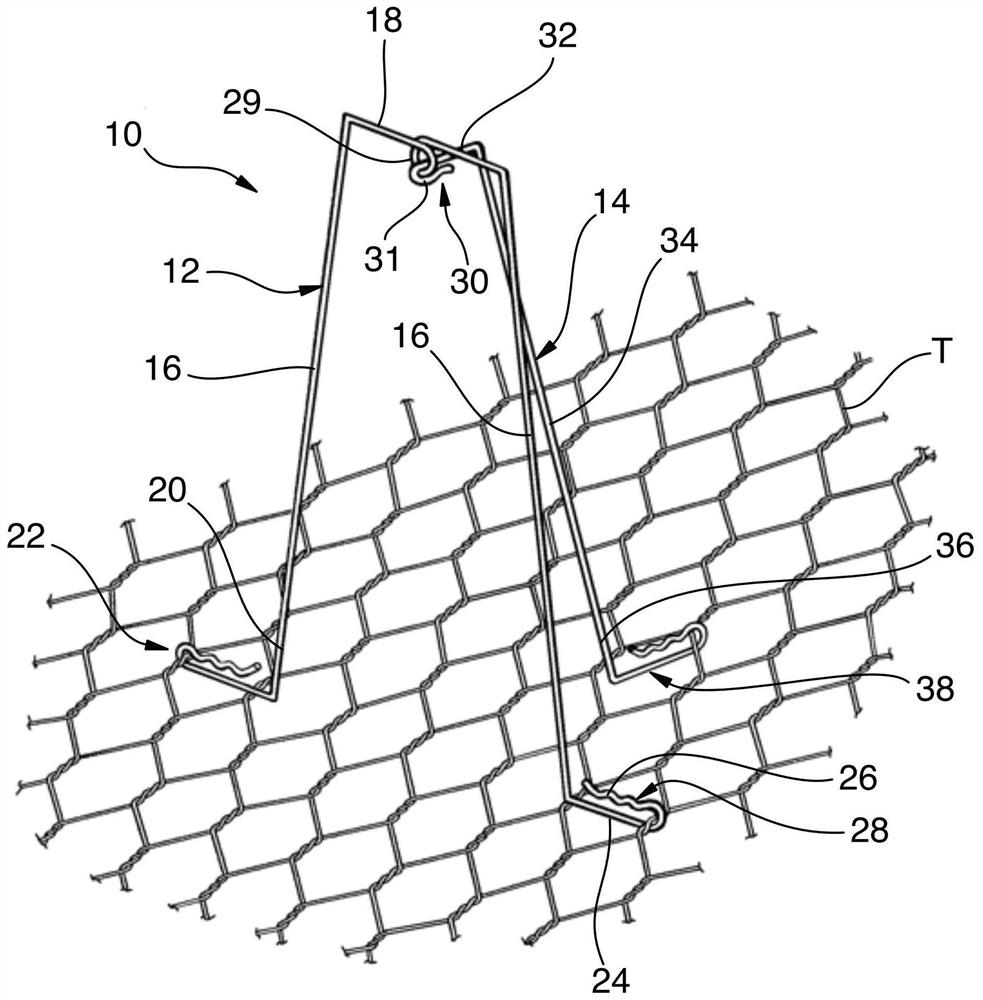

[0026] Refer below figure 1 , shows an embodiment of a support tie bar 10 incorporating aspects of the present invention for a net mat to be used to protect embankments, embankments, etc., as described above. The support tie rods 10 are shown in connection with the mesh T serving as the base of the cushion. For example, this is a sheet of metal wire mesh, such as a double twisted hexagonal mesh type, although the use of support ties for other types of mesh is not excluded.

[0027] figure 1 The support tie rod 10 shown in is shown in its operational state of use, prior to attachment to a mesh sheet serving as a cushion cover (not shown). In such an operating state, the support tie 10 is "self-stabilizing", a term understood to mean the characteristic of the support tie 10 standing independently in the form of a tripod or stand. The self-stabilizing operating state is a feature of the present invention common to all forms of support tie embodiments disclosed, described and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com