Split bus bar and application thereof

A busbar and split technology, applied in coupling devices, structural parts, electrical components, etc., can solve the problems of uneven load, unbalanced current, inconsistent battery life in the battery pack, etc., and achieve the effect of prolonging cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe the present invention in detail below in conjunction with accompanying drawing:

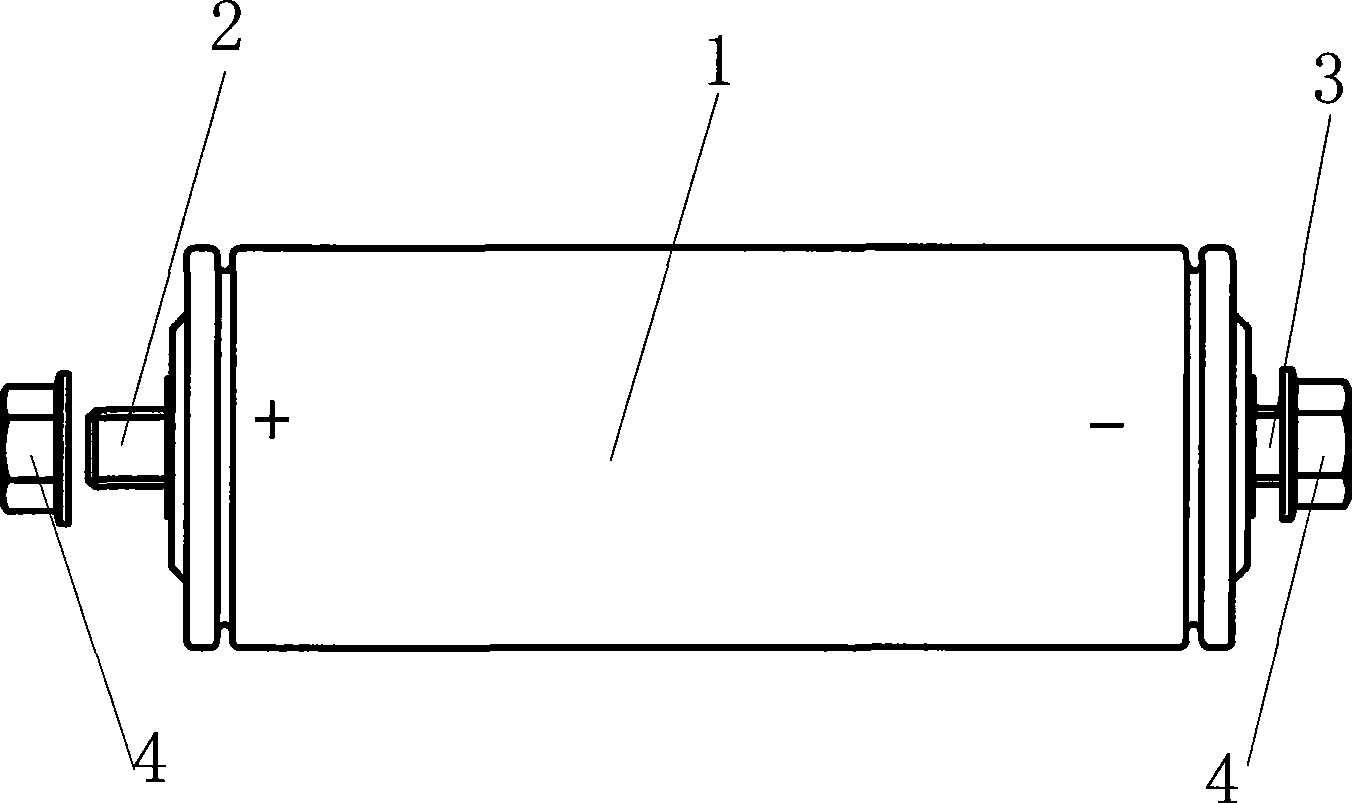

[0020] figure 1 Shown in is the battery 1 connected by the split busbar of the present invention, the positive pole and the negative pole of the battery 1 are made into the connection mode of bolt 2 and nut 4, which is convenient to better connect multiple such batteries 1 in parallel. Split busbars to form a battery pack.

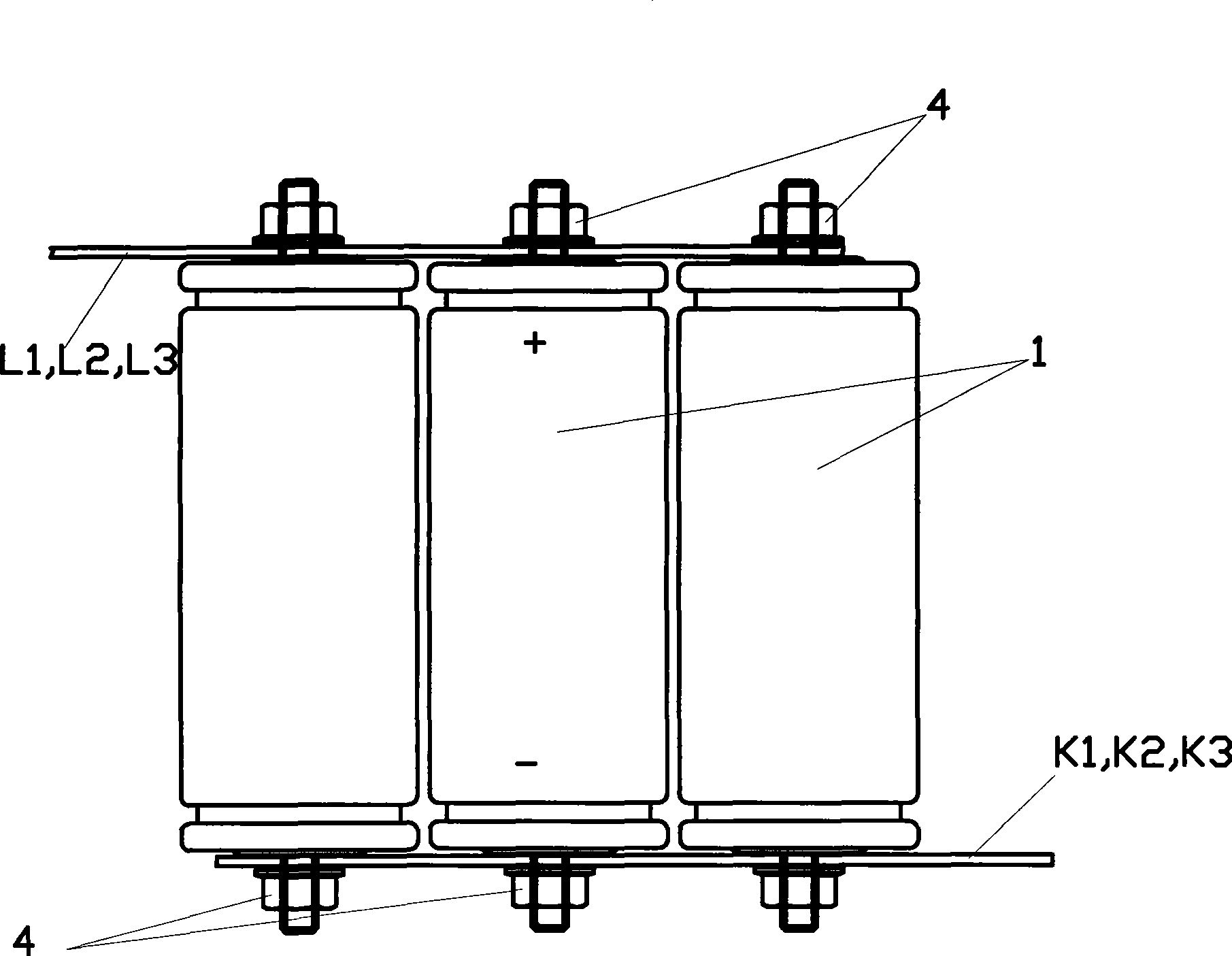

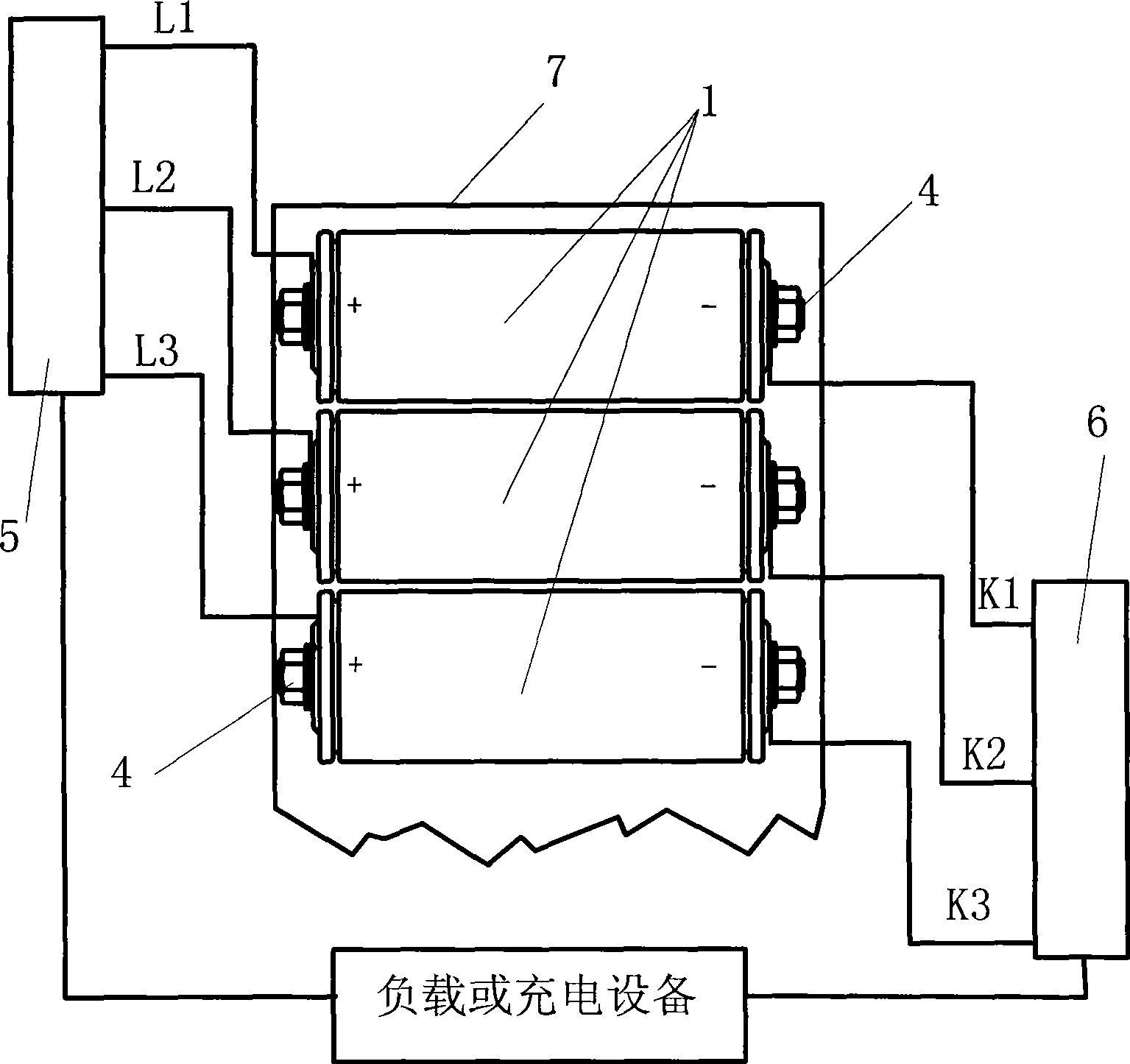

[0021] figure 2 A schematic diagram of a split busbar is shown in . Multiple batteries 1 are arranged side by side, and multiple batteries 1 (only 3 batteries are schematically shown in the figure) are connected in parallel through positive electrode split busbars L1, L2, L3 and negative electrode split busbars K1, K2, K3 , are interconnected through the holes on the busbar and the bolts and nuts 4 of each battery 1 to form a battery pack. Among them, the positive pole split busbars L1, L2, L3 lead out taps from one side, and the negative pole split busba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com