Efficient two-stage absorption refrigerating device

A technology of absorption refrigeration and high-pressure absorber, which is applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc. It can solve the problems of lower system performance coefficient, low system performance coefficient, and little performance improvement, and achieve a significant performance coefficient , broad application prospects, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

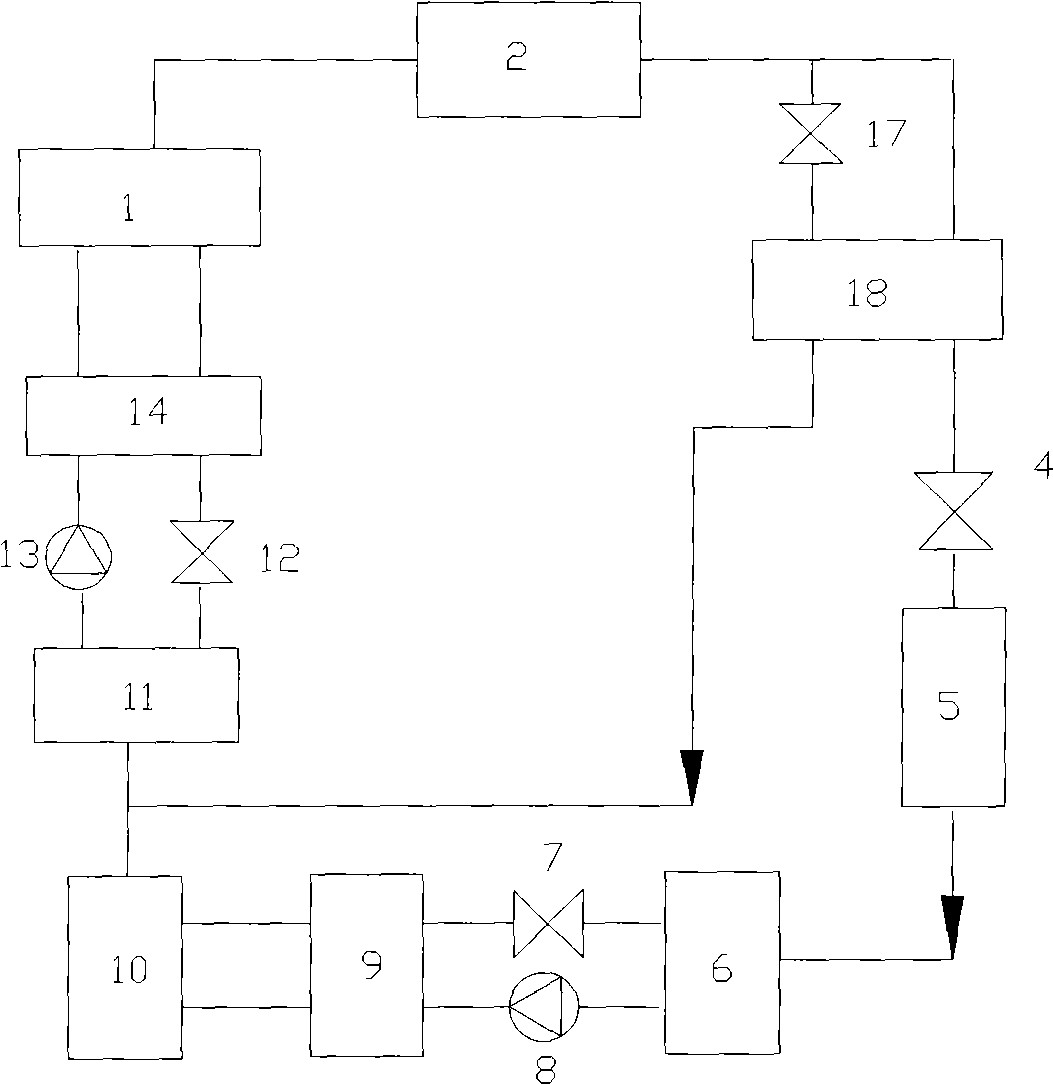

Image

Examples

Embodiment 1

[0019] Example 1 Using ammonia-water working medium as the working medium, the performance of the new device and the traditional device were simulated and calculated. Table 1 is a comparison of the performance of the new and old two-stage absorption refrigeration devices at different evaporation temperatures.

[0020] Table 1 Performance comparison of old and new two-stage refrigeration devices at different evaporating temperatures

[0021] parameter T g T k T e COP t COP n n 1 Q at Q an n 2 unit K K K / / % W W % Condition 1 375 310 238 0.820 0.093 13.5 14382 12928 10.1 Condition 2 375 310 240 0.136 0.152 11.9 9513.4 8720.2 8.33 Condition 3 375 310 242 0.157 0.175 11.2 8480.0 7831.0 7.65 Condition 4 375 310 244 0.174 0.192 10.3 7860.9 7317.6 6.91 Condition 5 375 310 246 0.186 0.204 9.46 7479.7 7009.7 6.28 Condition 6 375 310 248 0.197 0.215 8.73 7165.3...

Embodiment 2

[0029] In Example 2, the ammonia-water working medium pair was used as the assumption that the heat transfer temperature difference at the cold end of the subcooler was 5°C, and the performance of the new device and the traditional device were simulated and calculated. Table 3 shows the old and new devices at different evaporation temperatures. Comparison of the performance of two-stage refrigeration units.

[0030] Table 3 Performance comparison of old and new two-stage refrigeration devices at different evaporating temperatures

[0031] parameter T g T k T e COP t COP n n 1 Q at Q an n 2 unit K K K / / % W W % Condition 1 375 310 238 0.0820 0.0919 12.1 14382 13063 9.16 Condition 2 375 310 240 0.136 0.145 10.6 9513.5 8798.1 7.51 Condition 3 375 310 242 0.157 0.173 9.91 8480.0 7901.1 6.83 Condition 4 375 310 244 0.174 0.189 8.99 7860.9 7381.7 6.09 Condition 5 375 310 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com