Method and system for waste therophyte high-efficiency clean environment-protective cycled comprehensive utilization

A clean, environmentally friendly, plant-based technology, used in biofuels, special forms of dry distillation, petroleum industry, etc., can solve problems such as air pollution and large waste flue gas, and achieve the effects of inhibiting growth, restoring moisture, and purifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is a further detailed description of a method and system for efficient, clean, environmentally friendly, recycling and comprehensive utilization of waste raw plants of the present invention in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

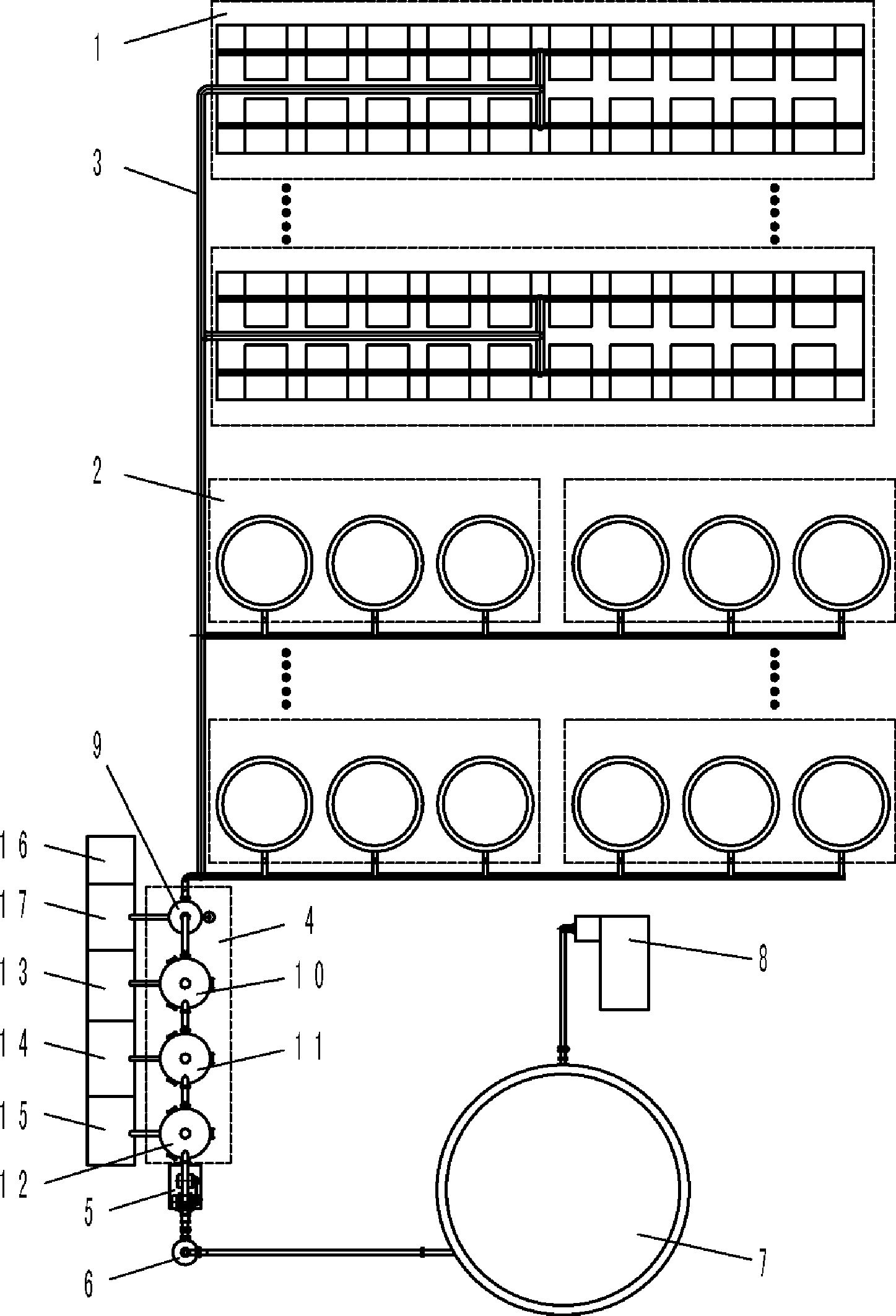

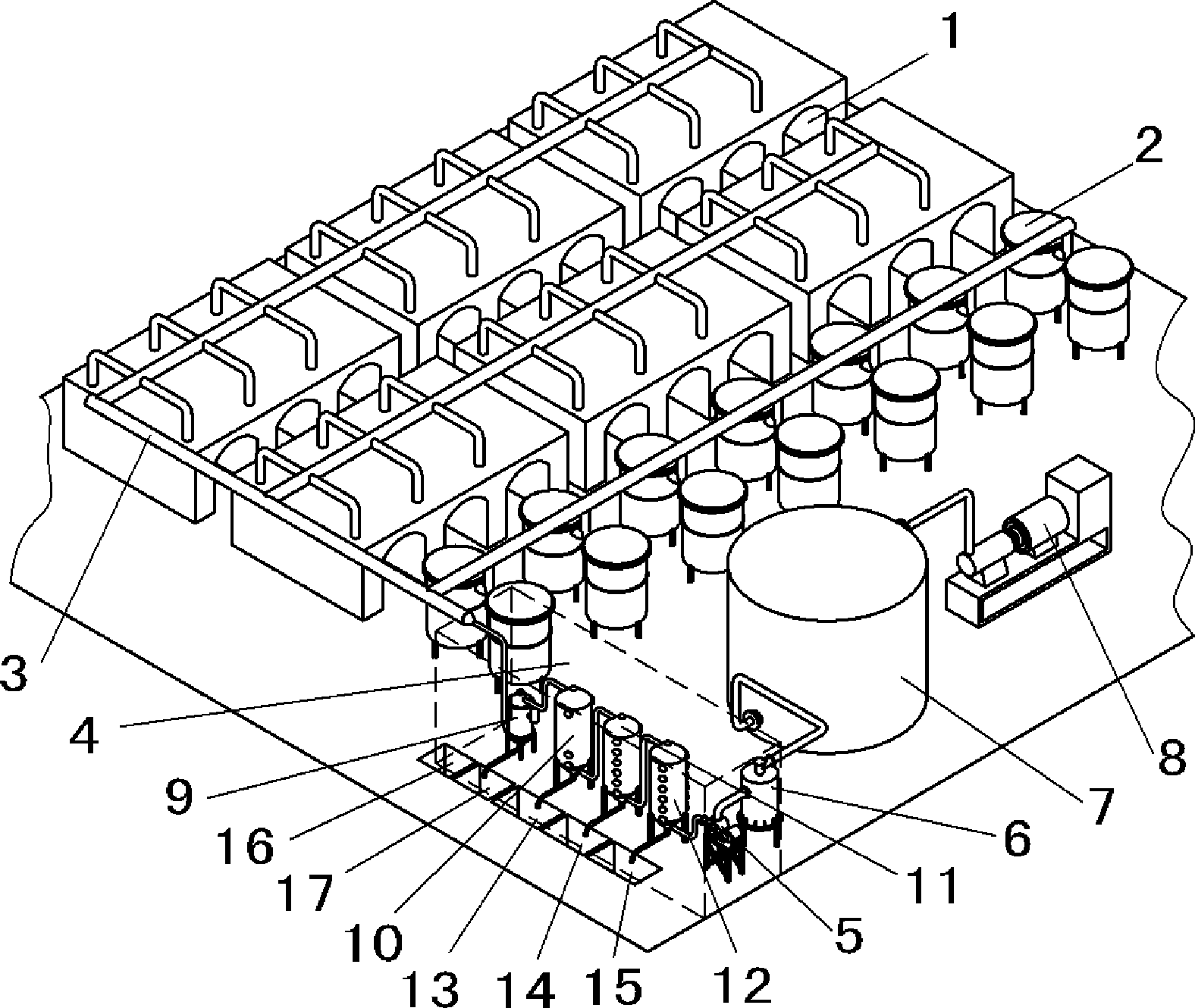

[0017] Example. A high-efficiency, clean, environmentally friendly, and comprehensive utilization method and system for waste raw plants. The method of the present invention is as follows: figure 1 and figure 2 As shown, the method is to use waste raw plants to make mechanism charcoal, and the flue gas generated in the charcoal making process uses separation equipment to separate the wood vinegar and wood tar in the flue gas from the flue gas, and the wood vinegar and wood tar are used as chemical Raw material, the separated flue gas is used as gaseous fuel. The machine-made charcoal made from the waste raw plants adopts a machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com