Lactalbumin polypeptide with antioxidation activity and preparation method thereof

A technology of whey protein peptides and antioxidant activity, which is applied in the fields of hydrolyzed protein components, animal protein processing, peptides, etc., can solve the problems such as no reports of whey protein antioxidant peptides, and achieve an improved level and high free radical scavenging , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

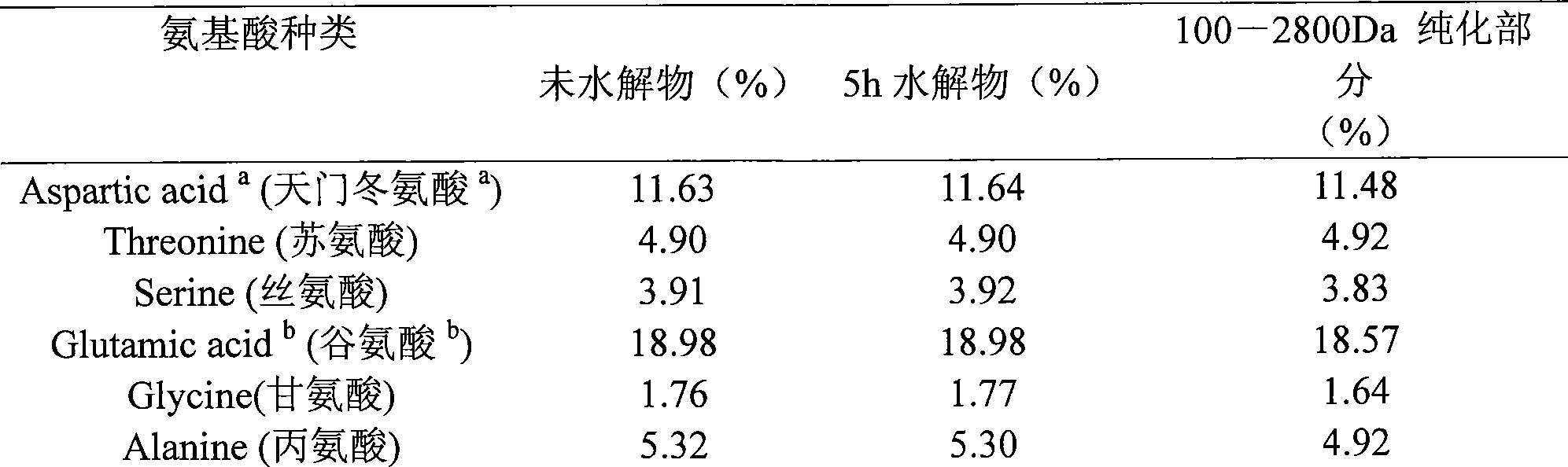

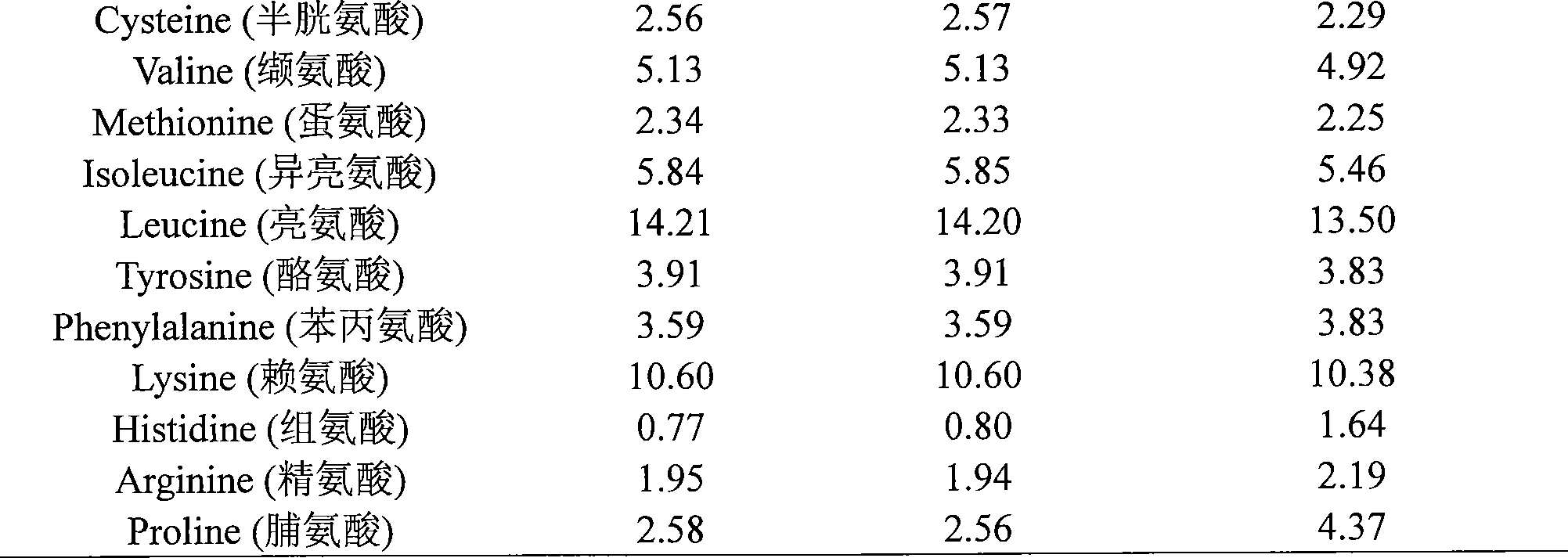

[0029] After the whey protein substrate with a concentration of 5% is heat-treated at a temperature of 95° C. for 5 minutes, the temperature is lowered to 60° C., and alkaline protease is added for hydrolysis. The concentration ratio of alkaline protease to whey protein substrate [ E / S] is 2:100, hydrolyzed for 5 hours at 60°C and pH 8.5 (the degree of hydrolysis (DH) reached 35.30% after testing); the hydrolyzate was boiled to kill the enzyme, cooled and concentrated , freeze-dried, that is. After testing, the prepared whey protein polypeptides are mainly composed of mixed whey protein polypeptides with a molecular weight between 100 and 400,000.

Embodiment 2

[0031] After the whey protein substrate with a concentration of 5% is heat-treated at a temperature of 95° C. for 5 minutes, the temperature is lowered to 60° C., and alkaline protease is added for hydrolysis. The concentration ratio of alkaline protease to whey protein substrate [ E / S] is 2:100, under the conditions of 55 ℃ temperature and pH value 8.5, hydrolyze for 5 hours (after testing, the degree of hydrolysis (DH) reaches 35.30%); the hydrolyzate is boiled, cooled, concentrated, after Sephadex G-10 gel chromatography separation and purification obtained a group of antioxidant peptide products with a molecular weight between 100-2800Da; After purification by reverse-phase high-performance liquid chromatography, a single peak of a peptide with higher activity was obtained, and the mass spectrometry (MS) measurement result showed that it was a mixed peptide composed of peptides with a molecular weight of 592.0; the peptide sequence is: Val-His- Leu-Lys-Pro.

[0032] The u...

Embodiment 3

[0037] After the whey protein substrate with a concentration of 5% is heat-treated at a temperature of 95° C. for 5 minutes, the temperature is lowered to 55° C., and alkaline protease is added for hydrolysis. The concentration ratio of alkaline protease to whey protein substrate [ E / S] is 3:100, hydrolyzed for 6 hours at a temperature of 55°C and a pH value of 8.0; the hydrolyzate is boiled, cooled, concentrated, and freeze-dried to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com