Special fixture for clamping thin workpieces

A technology for special fixtures and thin parts, applied in clamping, positioning devices, manufacturing tools, etc., can solve the problems of large processing deformation, reduced processing efficiency, poor workpiece rigidity, etc., to improve process rigidity, processing efficiency and precision. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

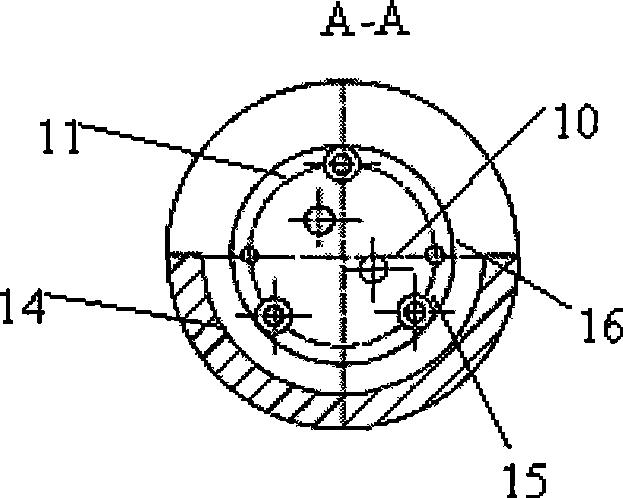

[0016] Figure 1 to Figure 5 As shown, it includes: head tip 1, middle gasket gasket 2, hole plug 3, head stopper 4, low melting point alloy 5, vacuum chamber 6, air guide hole 7, pipe joint 8, tail stopper 9. Tail double top 10, double top positioning plate 11, positioning bushing 12, double top seat 13, clamp body 14, screw 15, positioning pin 16, thin workpiece 17, head cover sealing ring 18, silica gel mud 19, spacer Stopper cover 20, movable baffle plate 21, spring 22, guide post 23, sealed water container 24, cover plate 25, mandrel 26 with swim bladder, anti-slip silicone ring 27, water 28 etc. in the container.

[0017] Such as figure 1 As shown, the clip body 14 is a semicircular tube structure with mounting shafts at both ends. The top tip 1 of the head is installed on the head shaft of the clamp body 14, and the extension length can be adjusted within a certain range. The tail double center point 10 is installed on the double center point seat 13, and can slide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com