Rice cooker and gas-liquid separating method for the steam cylinder of rice cooker

A technology of rice cooker body and rice cooker, which is applied in the direction of pressure cooker, etc., which can solve the problems of increased manufacturing cost, low yield rate, and many parts, and achieve the effects of reducing flow rate and pressure, saving production cost, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

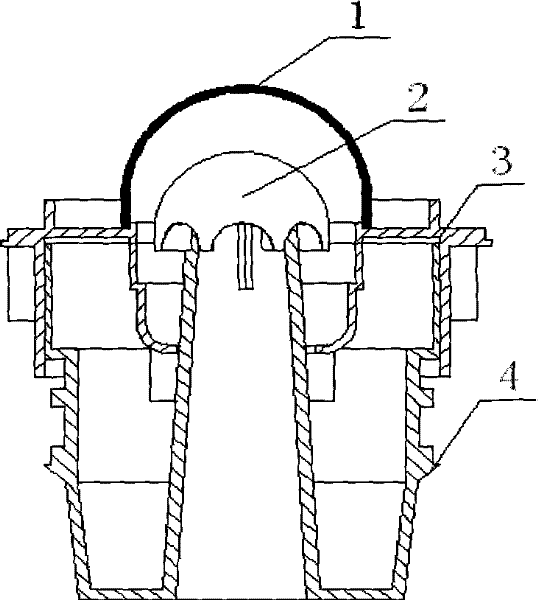

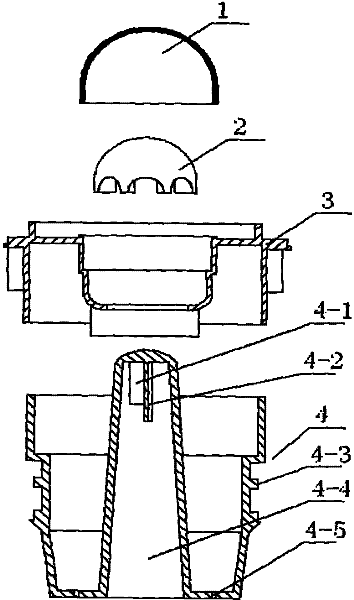

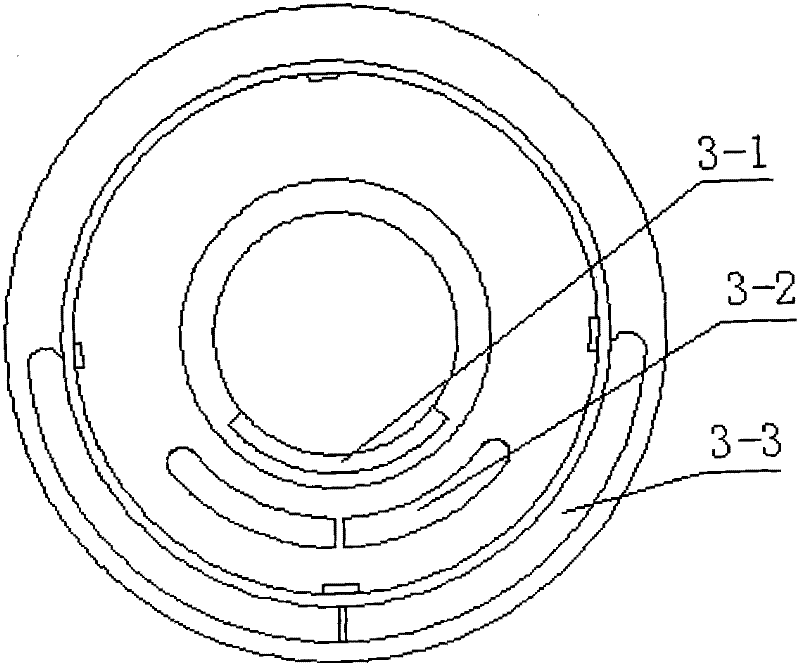

[0015] Embodiment 1: an electric rice cooker, comprising an electric rice cooker body and an outer cover of the electric rice cooker, the upper part of the outer cover of the electric rice cooker is provided with a steam cylinder, the steam cylinder is located in or on the cover of the outer cover of the electric rice cooker, and the middle part of the steam cylinder body 4 is provided with a protrusion for clamping Table 4-3. The steam cylinder body 4 is covered with a cylinder cover 3 and adopts mold injection molding. The cover surface of the cylinder cover 3 is provided with a diffuser window 3-2, and the cylinder cover body below the diffuser window 3-2 is provided with an (arc) air shield 3-1, and the cylinder cover 3 is provided with a semicircular groove along the back side 3-3. The purpose of doing like this is: the air diffuser window 3-2 can dissipate the liquid heat and the air pressure contained in the heat separated by the pneumatic rotary cover 2 through the he...

Embodiment 2

[0019] Embodiment 2: On the basis of Embodiment 1, a transparent cover 1 is provided above the pneumatic rotating cover 2. The transparent cover 1 is molded by injection molding and covered on the pneumatic rotating cover 2. The transparent cover 1 and the cylinder cover 3 are stuck together. It can not only prevent the user's fingers from touching the pneumatic rotating cover, but also facilitate the intuitive observation of the rotating state of the pneumatic rotating cover.

Embodiment 3

[0020] Embodiment 3: On the basis of Embodiment 1, the gas-liquid separation method of the steam cylinder of the electric cooker makes steam and rice water separated at the moment after being damped by the inner top of the steam channel 4-4, so that the rice water is separated by the steam channel 4-4. 4 The inner top damping directly falls back into the pot, so that the steam can push the pneumatic rotating cover 2 on the top of the steam channel 4-4 to rotate through two or more exhaust ports located on both sides of the steam channel 4-4, that is, to push the Pneumatic rotating hood 2 The blades 2-1 are driven by multiple pieces of airflow around the hood. During the rotation of the pneumatic rotating hood, the flow rate and pressure of the steam are further reduced, so that the steam is converted into a gas-liquid mixture, and the gas-liquid mixture is in the pneumatic rotating hood Under the action of the steam, the liquid in the steam is automatically separated and falls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com