Engine water pump leakage detecting device

An engine and water pump technology, applied in the field of engine water pump leak detection devices, can solve the problems of increasing the difficulty of engine sealing performance detection, unable to accurately display the location of leakage, affecting engine assembly efficiency, etc., and achieve accurate and reliable detection results. and reliable, reducing the workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments:

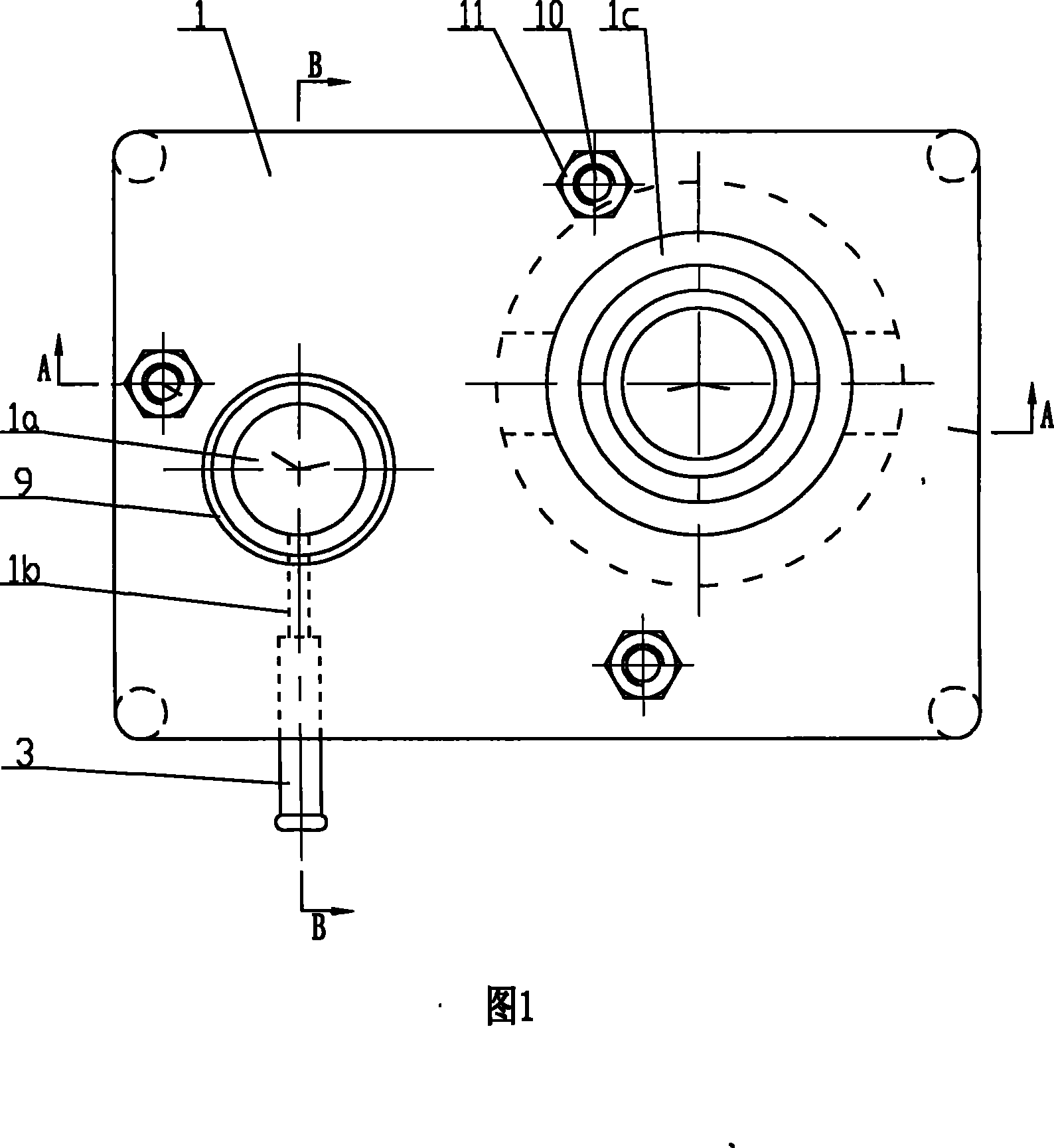

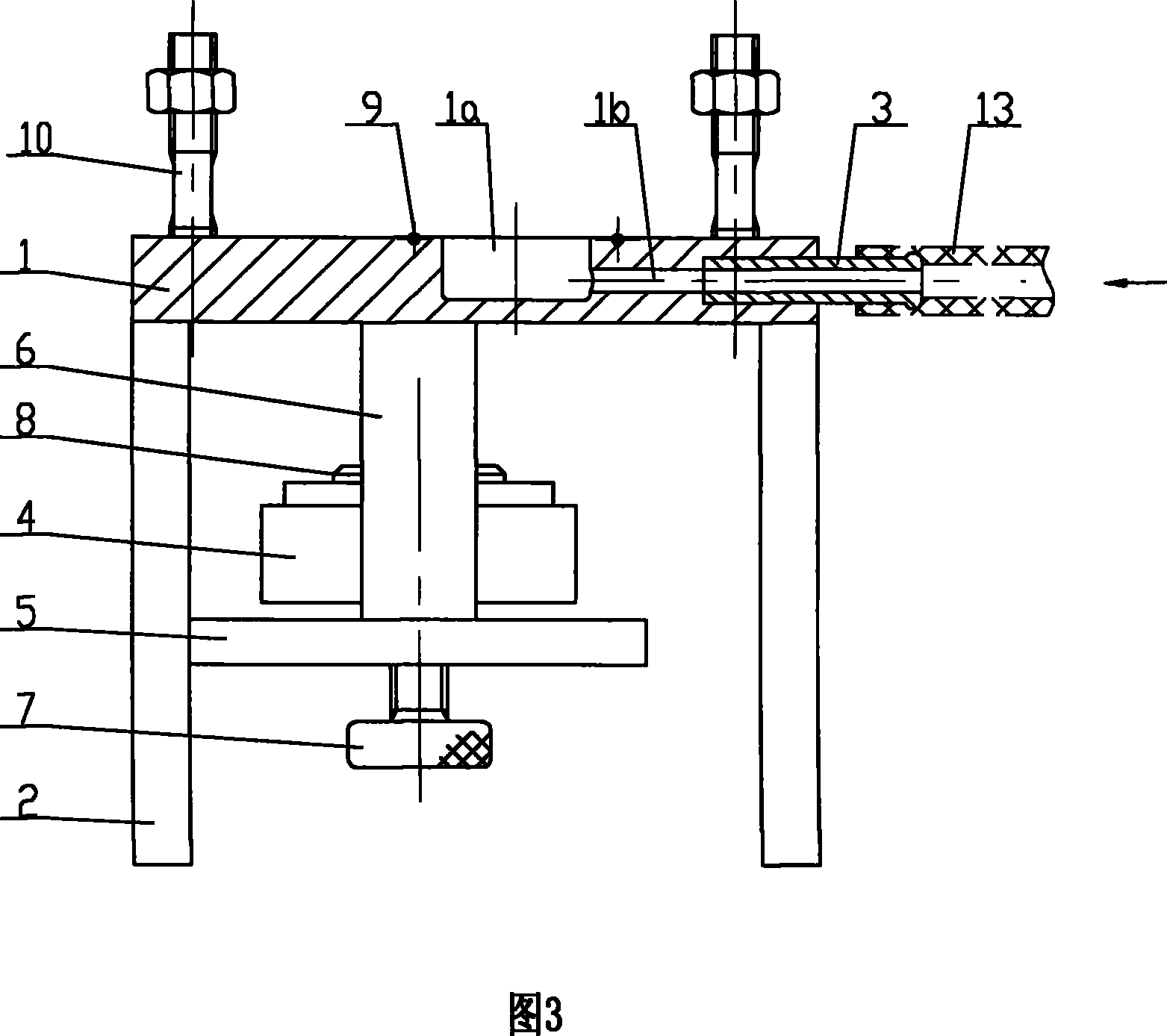

[0018] Such as figure 1 , figure 2 with image 3 As shown, the support platform 1 has a rectangular flat structure, and the four corners are supported by the uprights 2. Three stud bolts 10 distributed in a triangle are installed on the support table 1. The three stud bolts 10 correspond to the three mounting holes of the side water pump. The axis of each stud bolt 10 is perpendicular to the plate surface of the support table 1. The lower end of the bolt 10 is threaded with the support 1 (with threaded fastening glue), and a nut 11 is sleeved on the upper end of the stud bolt 10. A circular deep groove 1a, an annular shallow groove and an air inlet channel 1b are opened on the left part of the support platform 1, wherein the open end of the deep groove 1a is located on the upper surface of the support platform 1. The position and shape of the deep groove 1a And the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com