Supplementary food weighing and metering control device

A control device and feeding technology, applied in measuring devices, weighing, automatic feeding/discharging weighing equipment, etc., can solve the problems of low measurement control accuracy, and achieve the effect of optimization and amplification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe in detail the structure and characteristics of the present invention, give the following examples and illustrate as follows in conjunction with the accompanying drawings:

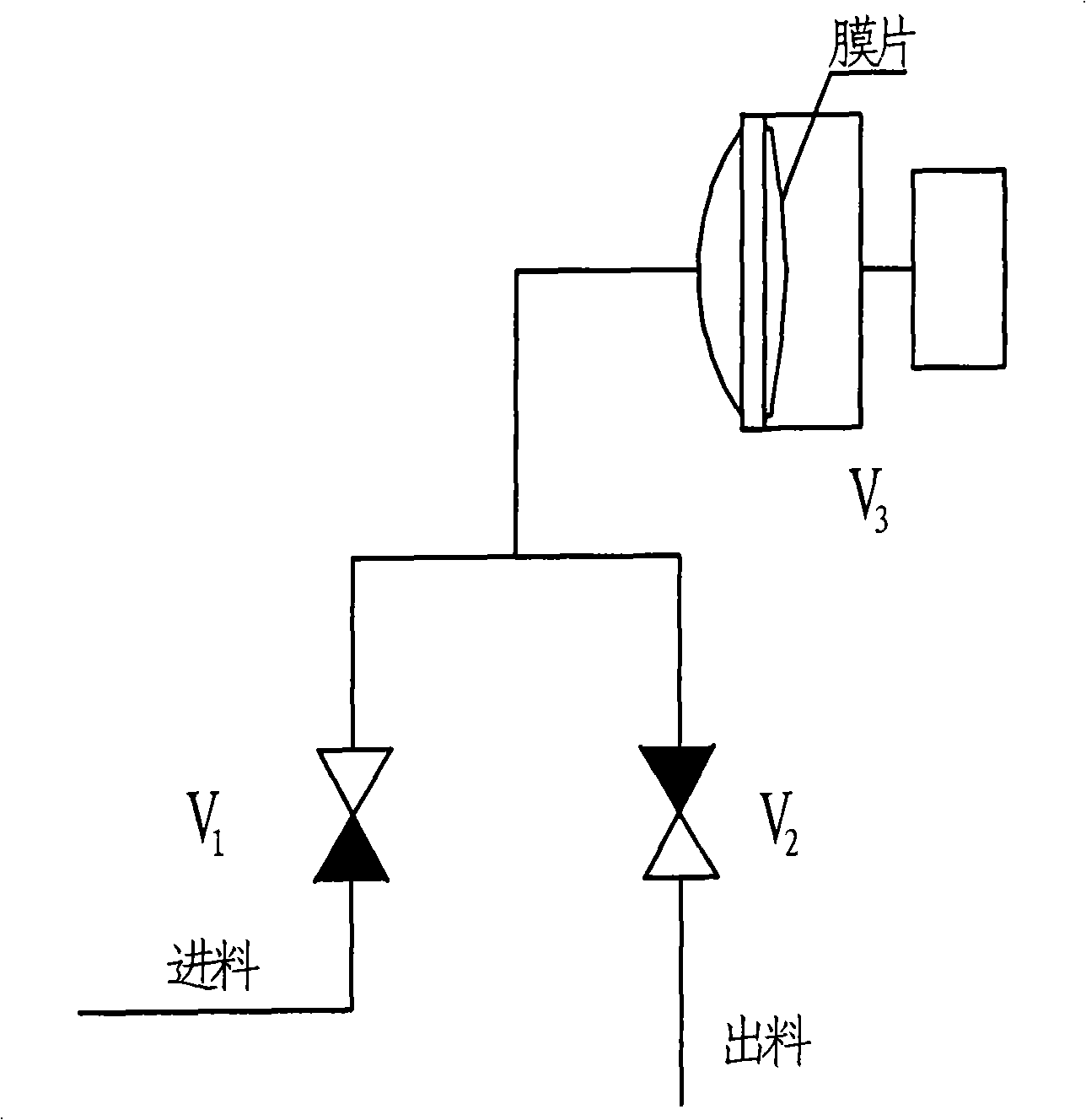

[0018] A feeding weighing metering control device, as attached figure 2 , image 3 As shown, it includes feeding cup 13, valve system, fermenter 1, feeding tank 23, and it is characterized in that it also includes:

[0019] A weighing system, the weighing system includes a load cell 24, a cantilever 25, a fixed support 9, a feed cup 13, the load cell 24 is connected with the support 9 by a cantilever 25, and the feed cup 13 is connected with the load cell 24, Weigh the feed liquid weight in the feeding cup 13 by weighing sensor 24;

[0020] An electronic monitoring system consisting of figure 2 As shown, it includes a controller composed of input / output modules, alarm and display devices, and an industrial computer system composed of keyboard, mouse, touch screen, comparator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com